– 49 –

Procedures of assembling and adjustment procedures

1. Push the needle thread clamp device

❸

in the direction of A and x it with the three (LK-1900BB,

1903BB, 1900BNB, 1903BNB : four) setscrews

❷

. Tighten the hinge screw

❶

.

2. Attain "07 Needle thread clamp motor origin adjustment" of the check program.

3. Try to tread on the pedal for origin retrieval.

4. Keep pressing the [+] key and move the needle thread clamp release plate

❹

to the most advanced

position.

At that time, conrm that the needle thread clamp motor does not suffer from step-out (position shift).

If step-out should occur, slightly move the needle thread clamp device

❸

behind (in the direction of the

arrow A) and make readjustment from step "3." above.

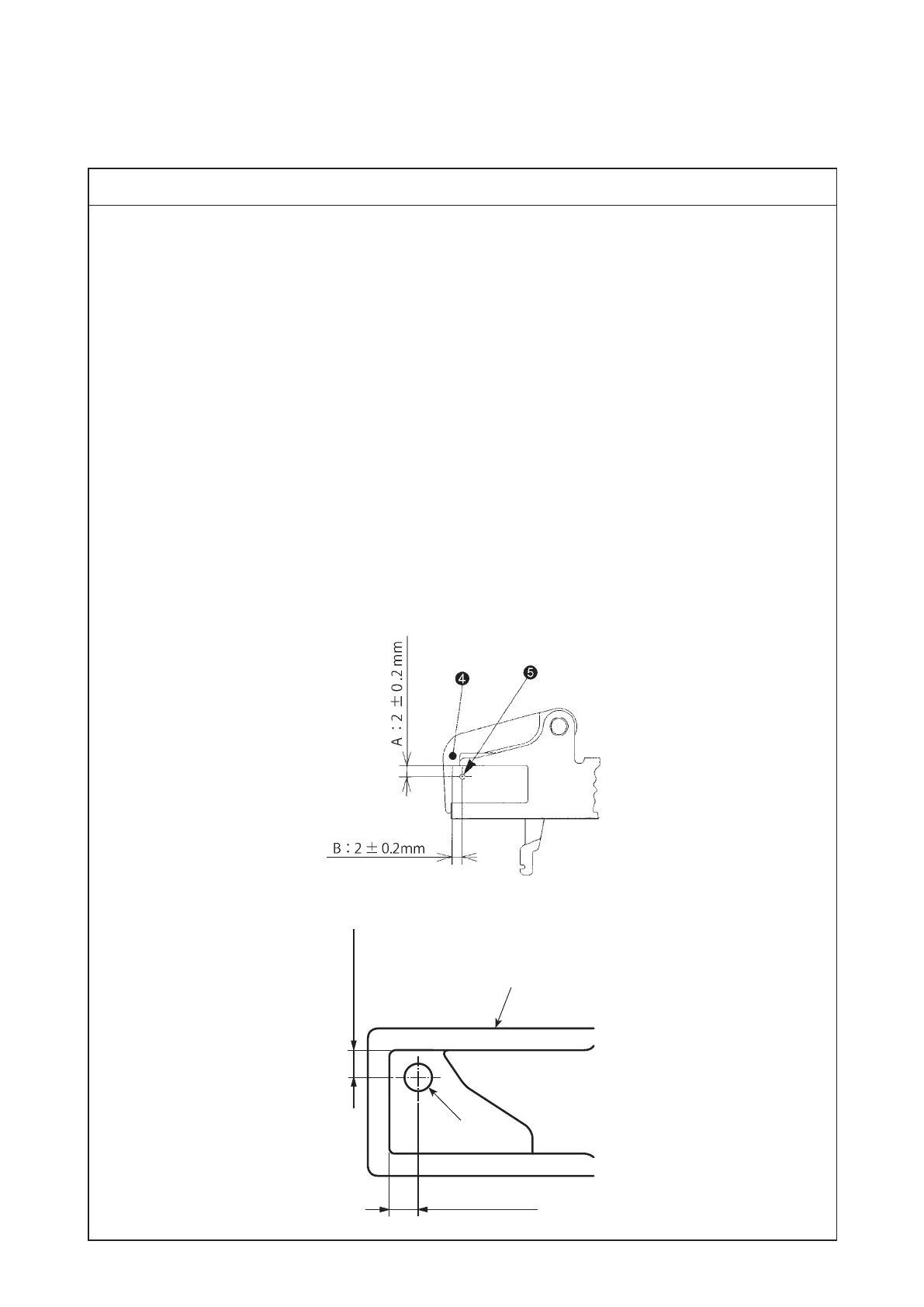

5. Conrm that the distance between the needle thread clamp release plate

❹

and center of the needle

❺

is A : 2 ± 0.2 mm and B : 2 ± 0.2 mm (LK-1900BB, 1903BB, 1900BNB, 1903BNB → A : 2 ± 0.3 mm, B :

2 ± 0.5 mm), respectively.

6. If the distance seems to be inadequate, loosen the three setscrews

❷

and move the needle thread

clamp device

❸

for adjustment.

(Caution) For the prevention of injury, the distance should be checked in the check program 07.

7. After the completion of the above-mentioned reassembly, make adjustments according to "3.-(36) Ad-

justment of the needle thread clamp reference position".

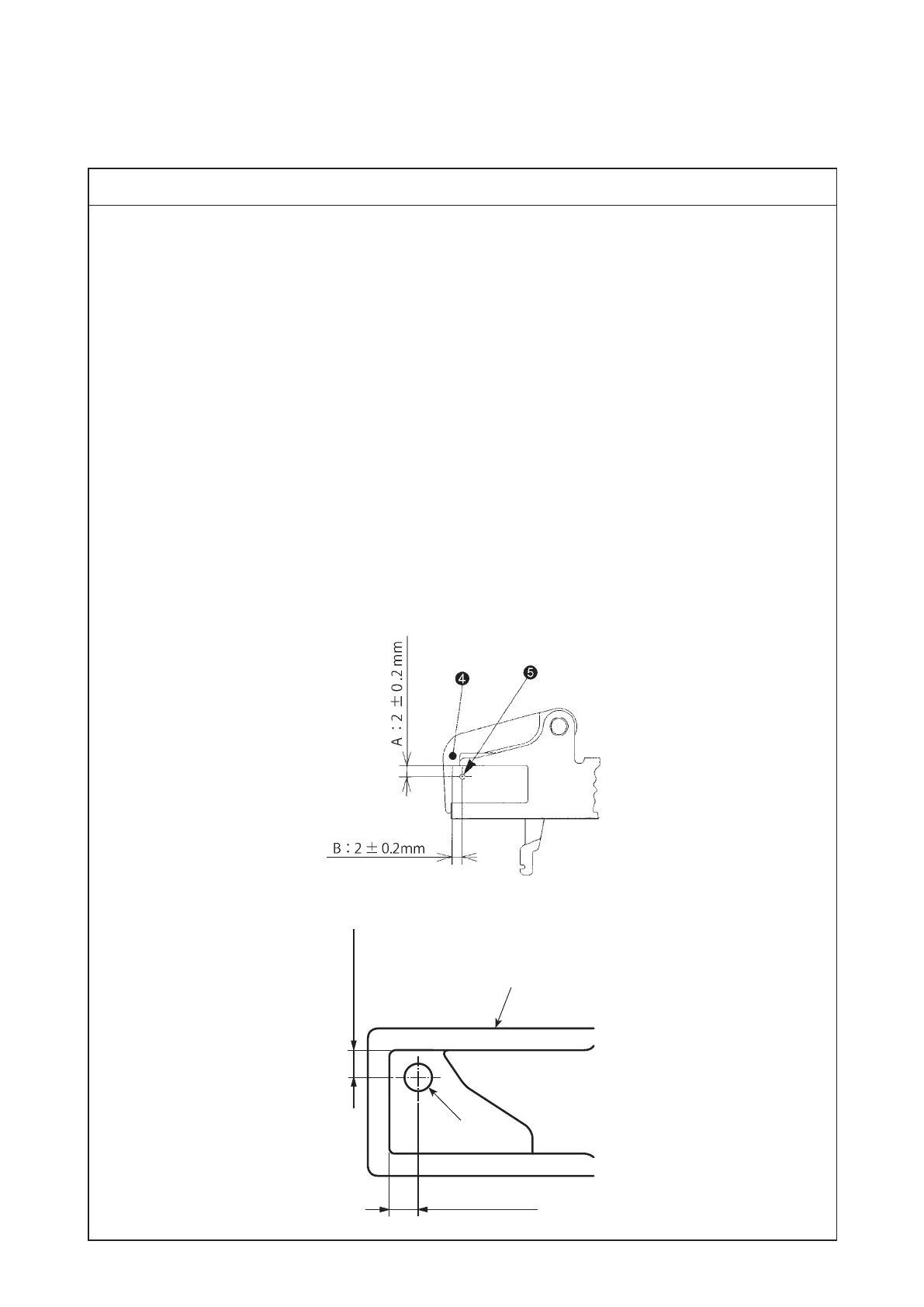

B : 2 ± 0.5 mm

A : 2 ± 0.3 mm

❺

❹

[LK-1900BB, 1903BB (Short tail application]]

Loading...

Loading...