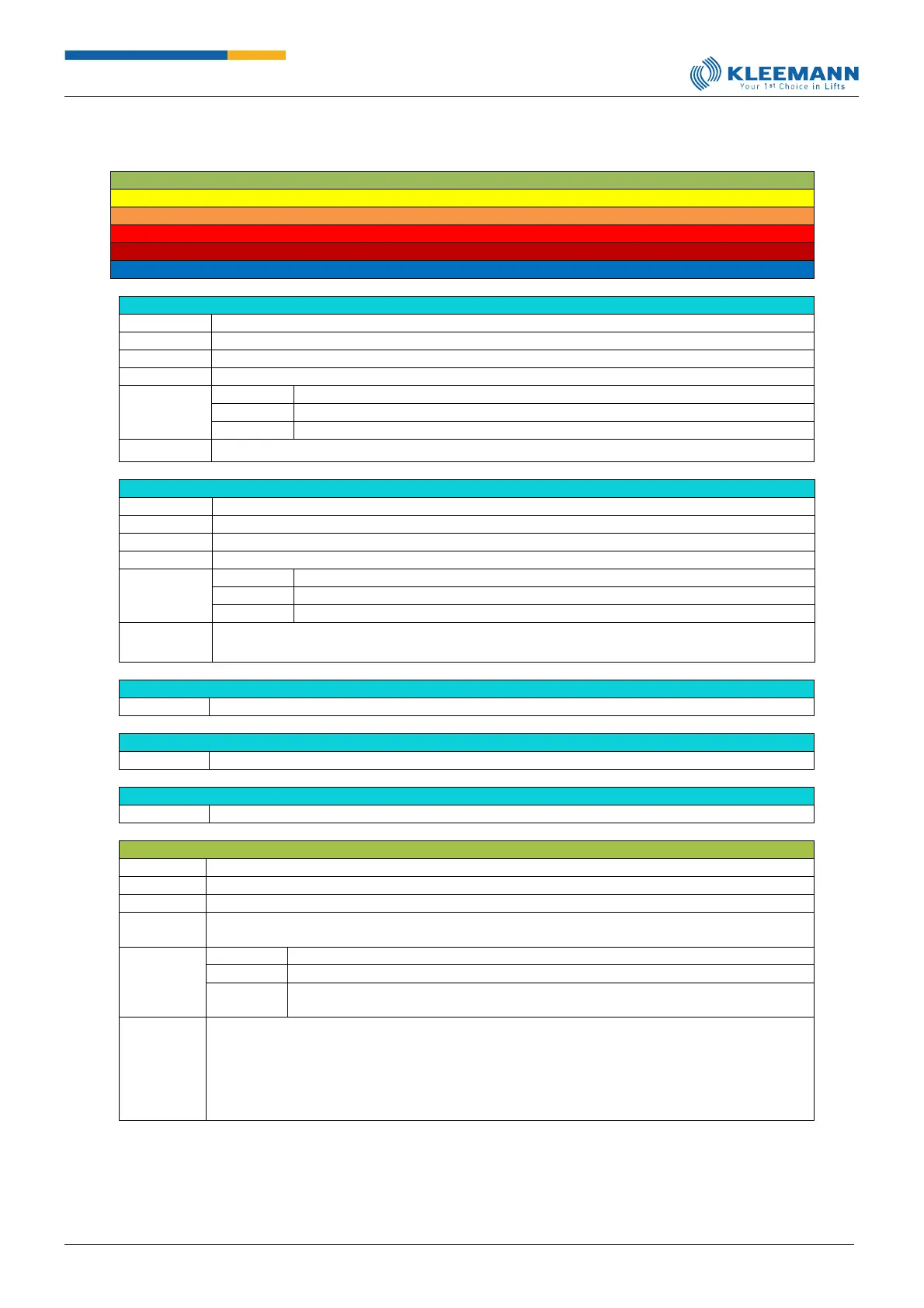

Errors that are reset automatically.

Errors that are reset both manually and automatically.

Errors which need to be reset manually by entering 800+OK.

Errors which need to be reset manually by entering 700+OK.

Errors which require a reset procedure.

Notifications which are reset automatically.

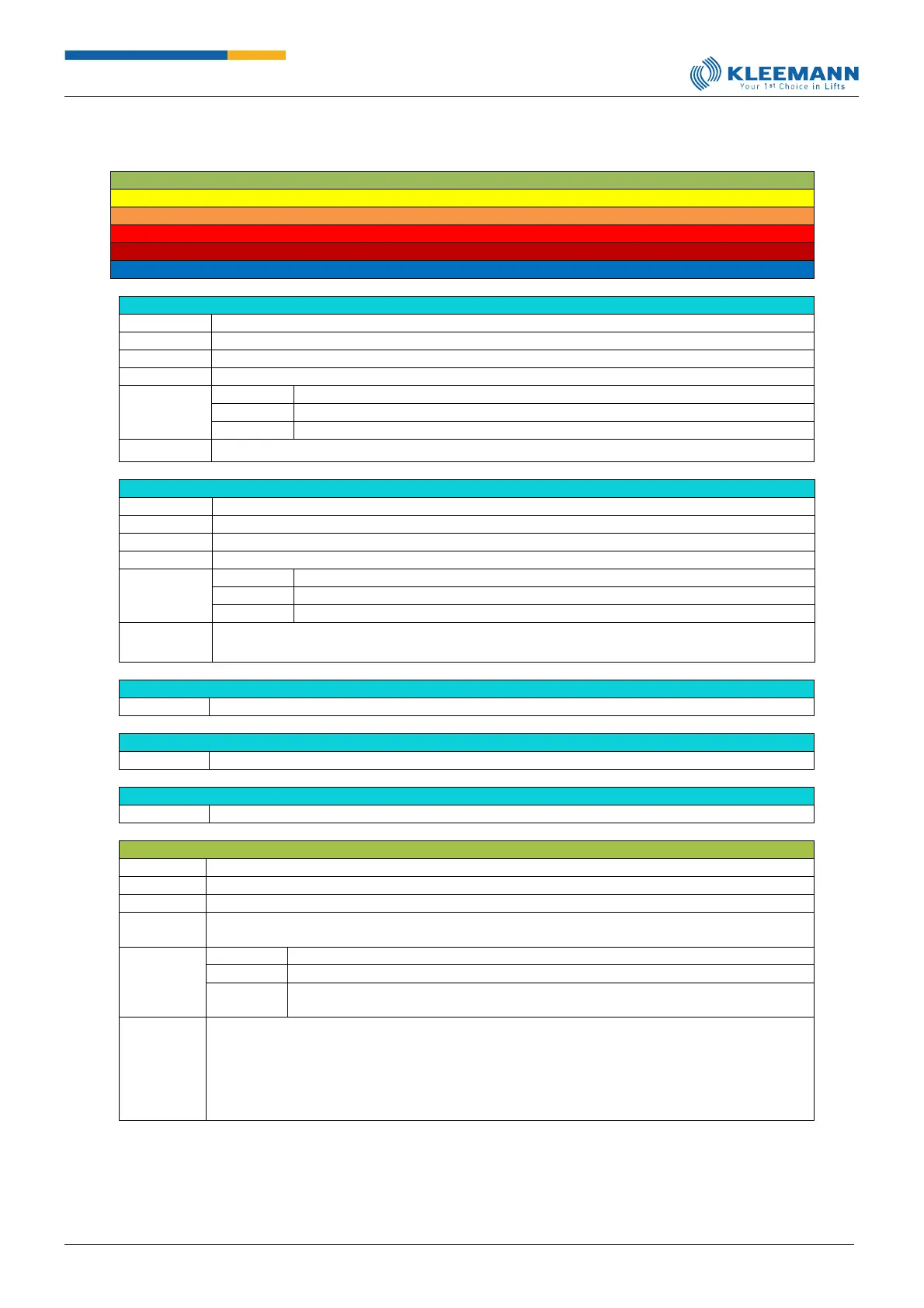

Critical module not\alive!

A function was programmed to a non-existing Bus-module.

The control switches into “out-of-order” mode.

- Install the missing module

- Re-programm the desired function on an existing module

800 + Ok / Recall / Reset

The control contact of safety relay K5 reports a permanently deenergized relay despite the zone being

approached or travelled through.

The control switched into “out of operation 5“

The control stops in the next possible landing.

The control stops in the next possible landing and descends into the lowest landing from

there.

- Check selection signals SM/SZ (First SZ and then SM must turn active when approaching the

zone).

- Check selection signals for voltage (When a signal is active one should be able to measure a

24V voltage between the signal and +24V).

- Check the DIL switch “S1“ on the KMREL board (All switches must be positioned on “off”)”

- Check the jumper “J3“(refer to the wiring diagram)

Loading...

Loading...