KW Aufzugstechnik GmbH OPERATING MANUAL DAVID-613

DAVID-D613-V125-E 13.04.2021 Page - 22 -

2. Perfomance description

2.1 Range of services oft he micrprocessor system DAVID-613

The highly flexible microprocessor control system DAVID-613 enables the realization of rope, hydraulic,

chain, rack, stationary & traveling drives, passenger and goods lift systems also with pin placement

device of all kinds according to EN81-20, EN81-1 / 2, MRL & ATEX, with up to eight group lifts, and a

maximum floor space of 64 stops and up to 3 door sides. This type diversity is included extensively in

the standard software.

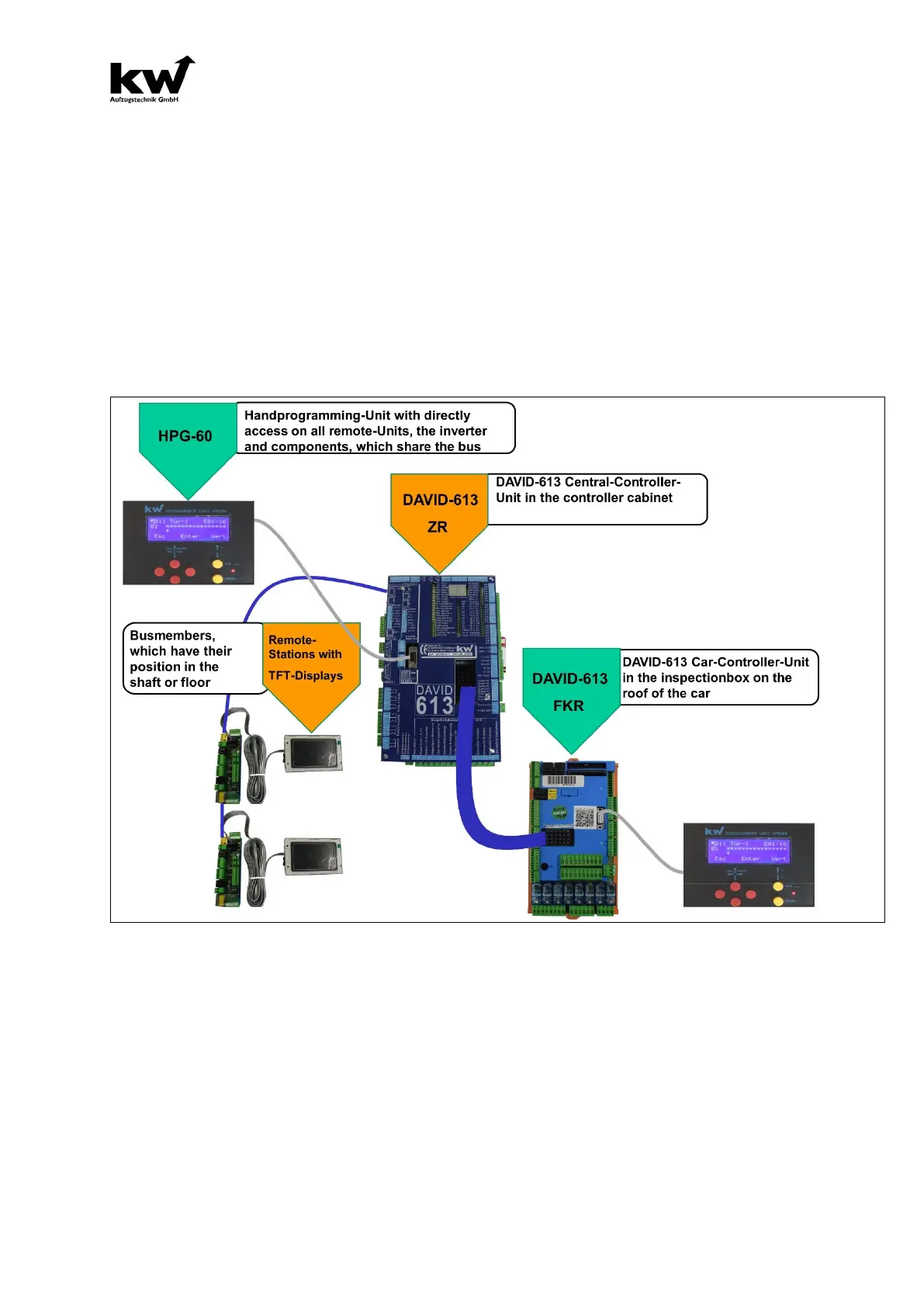

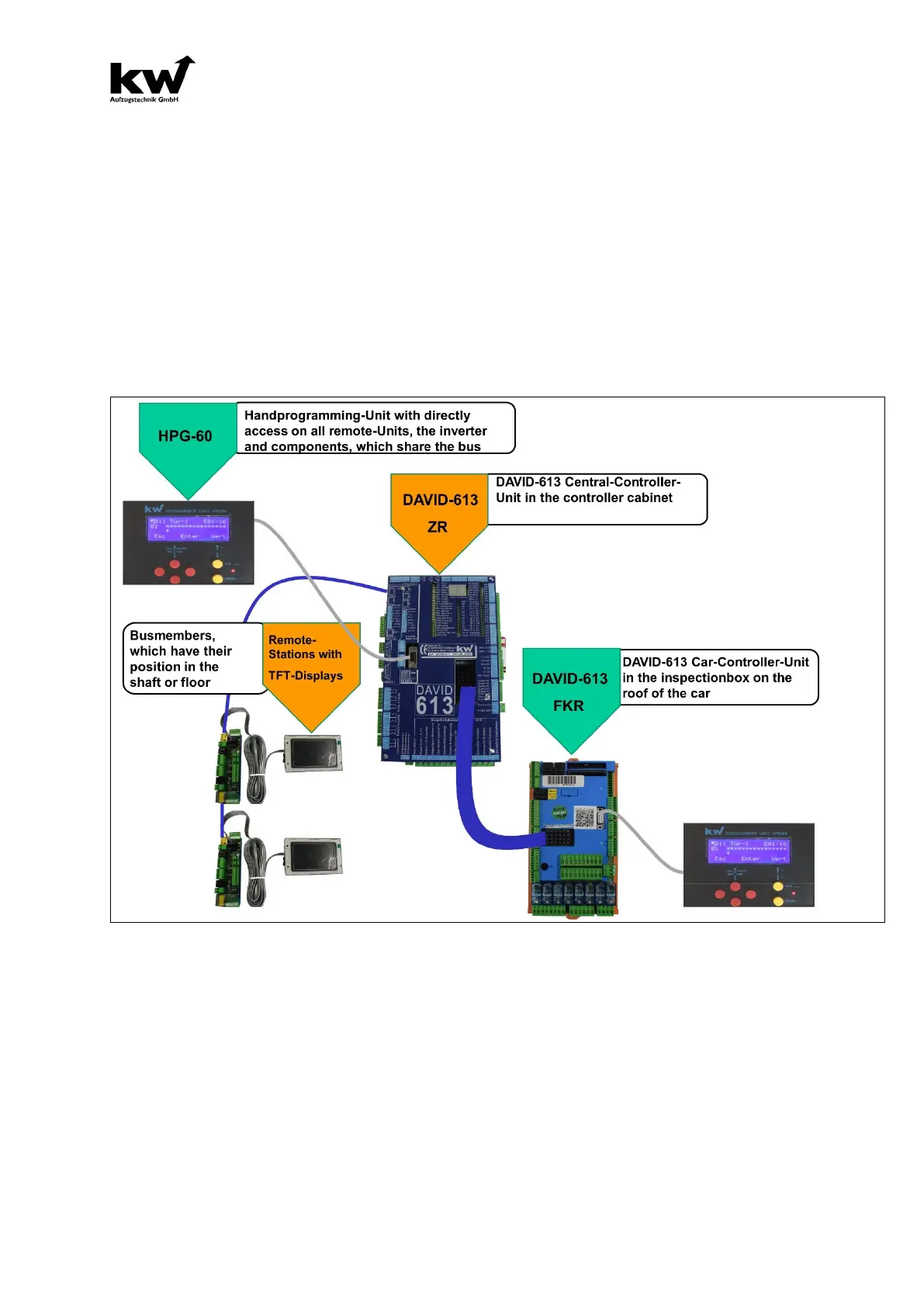

The control concept of the DAVD-613 is a decentralized topology that lets its members communicate

via the bus connections. The master structure is located in the central controller (ZR) which communi-

cates with the car controller (FKR) via the bus on the car and in the individual floors via the remote-

stations in the floors (ER).

Topologie of the DAVID-613 Controller-System

2.2 Device description Central Controller ZR

The standard software included in the control computer includes the setting of all types of elevators. All

functions such as selective door controls, evacuations, FW controls, priority retries, group operation,

energy management, lift warden function, access management ... can be set on site.

All inputs and outputs are freely programmable and can be assigned with over 2000 input and output

functions. The function library is part of the control system.

The control system DAVID-613, as well as its predecessors, have 12 information taps from the safety

circuit of the elevator system to perform an accurate and fast safety circuit diagnosis.

The control computer has a metal housing to fully encapsulate the internal electronics. The radiation

emissions of the device are extremely low, but the device has a high resistance to external radiation.

The emission complies with EN 55011 Level B, with the control cabinet open.

All printed circuit boards are coated with insulating varnish on both sides (coating). As a result, the

overall system gains in stability against condensation in the case of strong temperature fluctuations and

dielectric strength when foreign bodies penetrate.

Loading...

Loading...