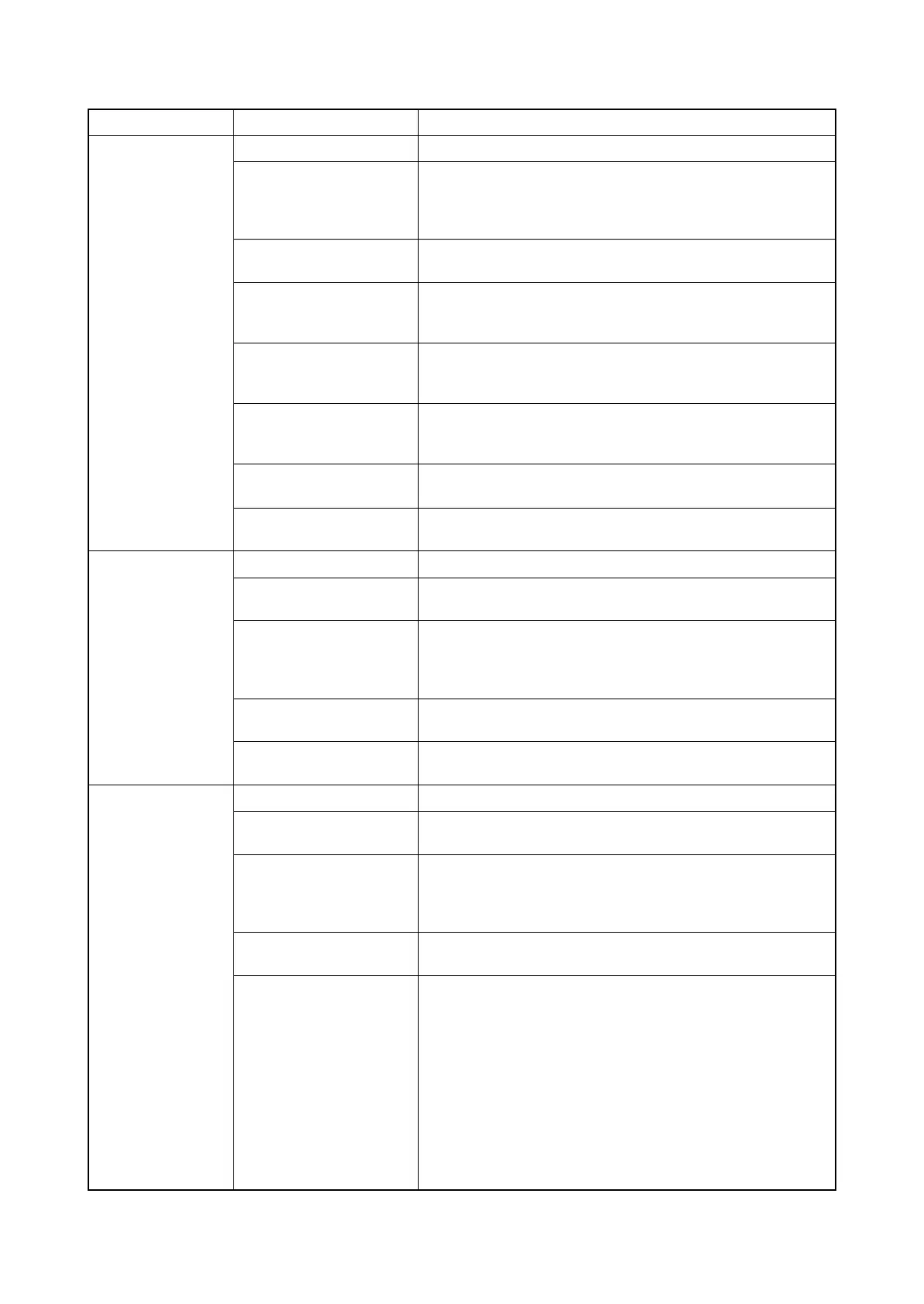

2KA

1-4-12

(6)

A paper jam in the

paper feed section is

indicated during

copying (no paper

feed from MP tray).

Jam code 14

Paper is extremely curled. Change the paper.

Check if the MP paper feed

pulley, MP forwarding pulley

and MP separation pulley

are deformed.

Check visually and replace any deformed pulleys (see page 1-5-

8).

Broken MP paper feed

switch actuator.

Check visually and replace switch.

Defective MP paper feed

switch.

Run maintenance item U031 and turn MP paper feed switch on

and off manually. Replace the switch if indication of the corre-

sponding switch is not displayed in reverse.

Check if clutch malfunc-

tions.

Run maintenance item U032 and select MP paper feed clutch or

MP paper conveying clutch to be turned on and off. Check the sta-

tus and remedy if necessary.

Electrical problem with MP

paper feed clutch or MP

paper conveying clutch.

Check (see page 1-4-63).

Defective MP solenoid. Run maintenance item U033 and select MP solenoid to be turned

on and off. Check the status and remedy if necessary.

Electrical problem with MP

solenoid.

Check (see page 1-4-64).

(7)

A paper jam in the

paper feed section is

indicated during

copying (misfeed in

3000-sheet paper

feeder horizontal

paper conveying sec-

tion).

Jam code 15

Paper is extremely curled. Change the paper.

Check if the paper side

guides are deformed.

Check visually and replace.

Defective paper path sen-

sor 3.

With 5 V DC present at CN6-12 on the PF main PWB, check if

CN6-11 on the PF main PWB remains low or high when paper

path sensor 3 is turned on and off. If it does, replace paper path

sensor 3.

Check if PF paper feed

clutch 2 malfunctions.

Run maintenance item U247 and select PF paper feed clutch 2 to

be turned on and off. Check the status and remedy if necessary.

Electrical problem with PF

paper feed clutch 2.

Check (see service manual of 3000-sheet paper feeder).

(8)

A paper jam in the

paper feed section is

indicated during

copying (misfeed in

3000-sheet paper

feeder horizontal

paper conveying sec-

tion).

Jam code 16

Paper is extremely curled. Change the paper.

Check if the paper side

guides are deformed.

Check visually and replace.

Defective paper path sen-

sor 2.

With 5 V DC present at CN6-9 on the PF main PWB, check if

CN6-8 on the PF main PWB remains low or high when paper path

sensor 2 is turned on and off. If it does, replace paper path sensor

2.

Check if PF paper feed

clutch 1 malfunctions.

Run maintenance item U247 and select PF paper feed clutch 1 to

be turned on and off. Check the status and remedy if necessary.

Electrical problem with PF

paper feed clutch 1.

Check (see service manual of 3000-sheet paper feeder).

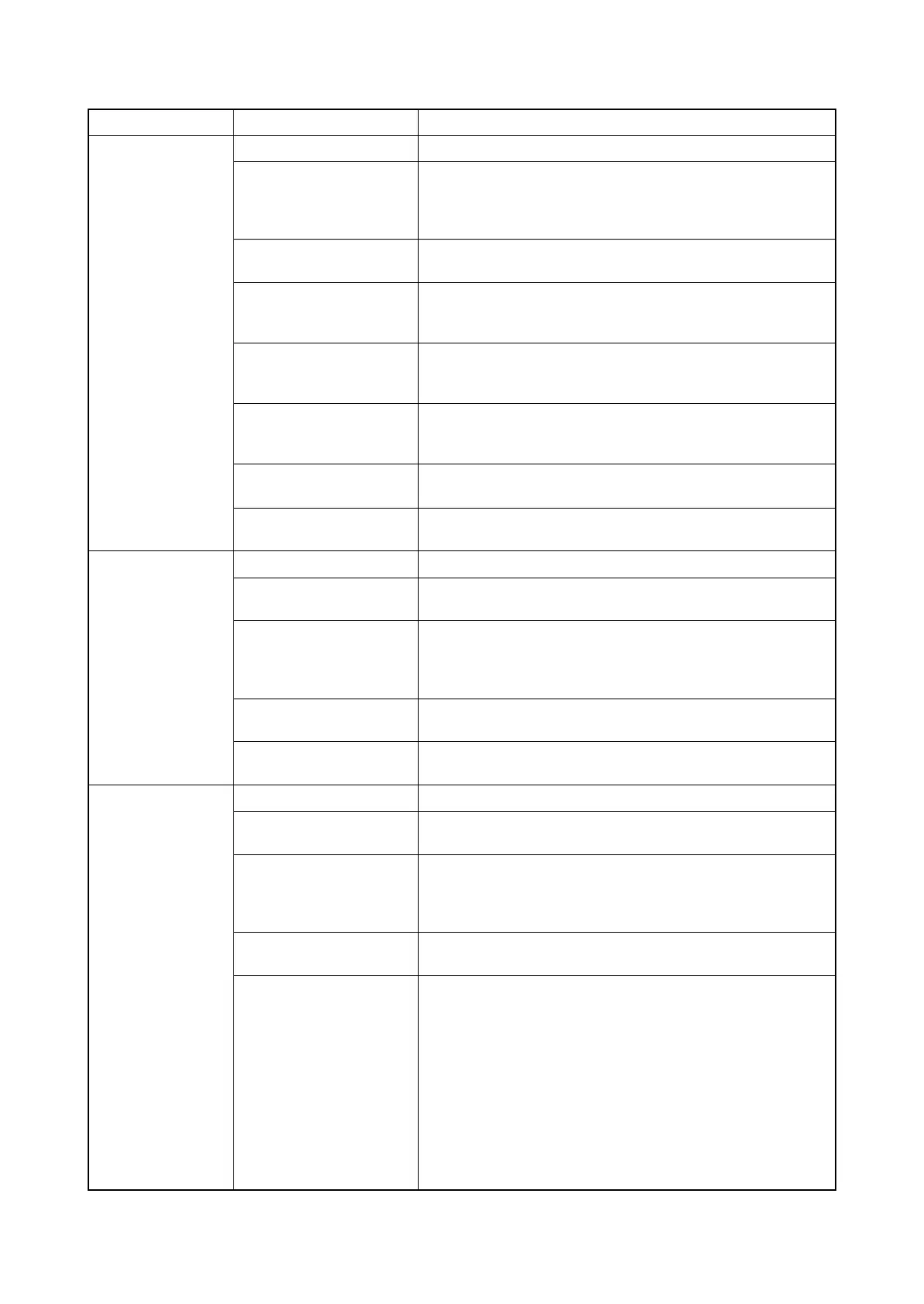

Problem

Causes/check procedures

Corrective measures

Loading...

Loading...