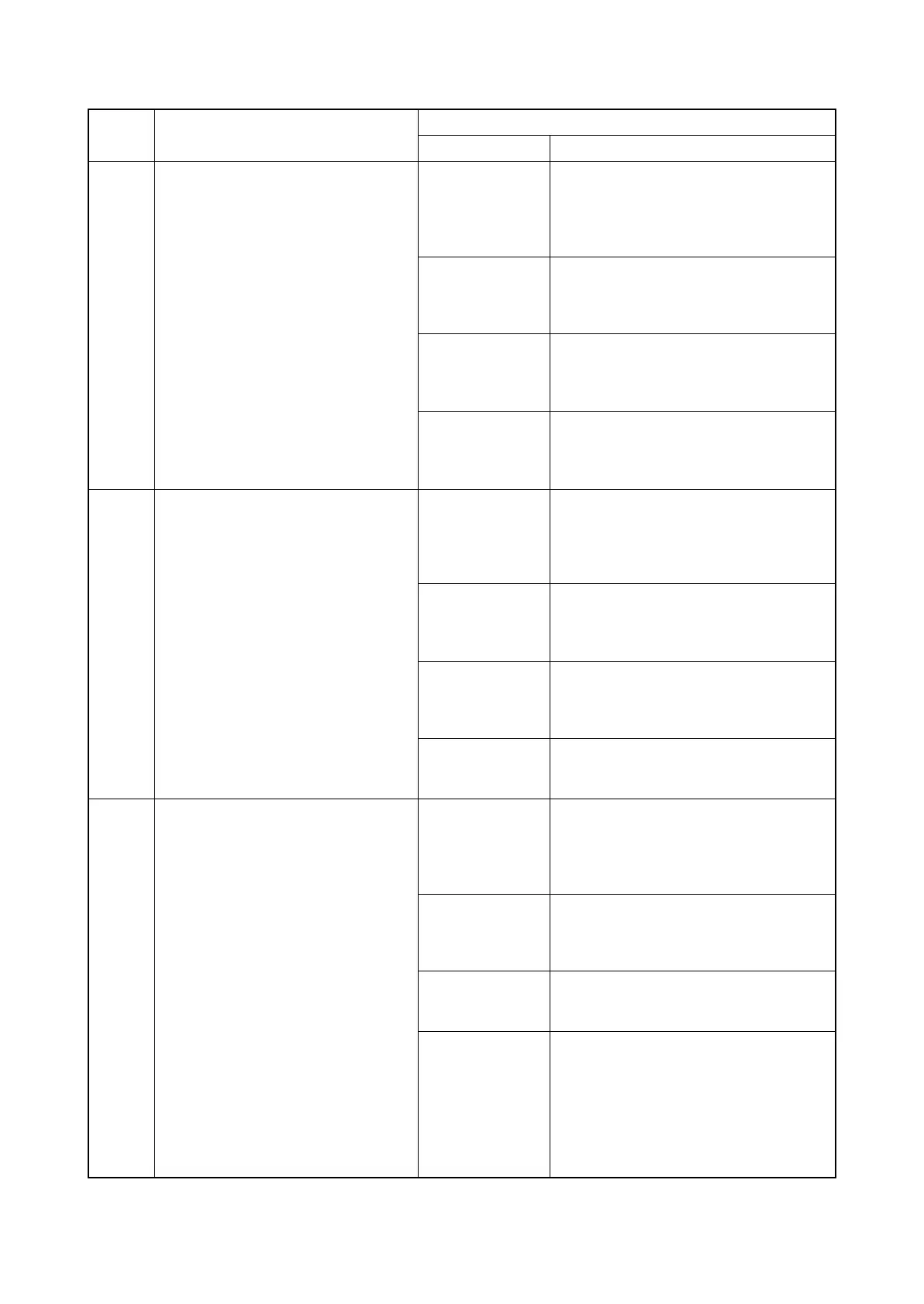

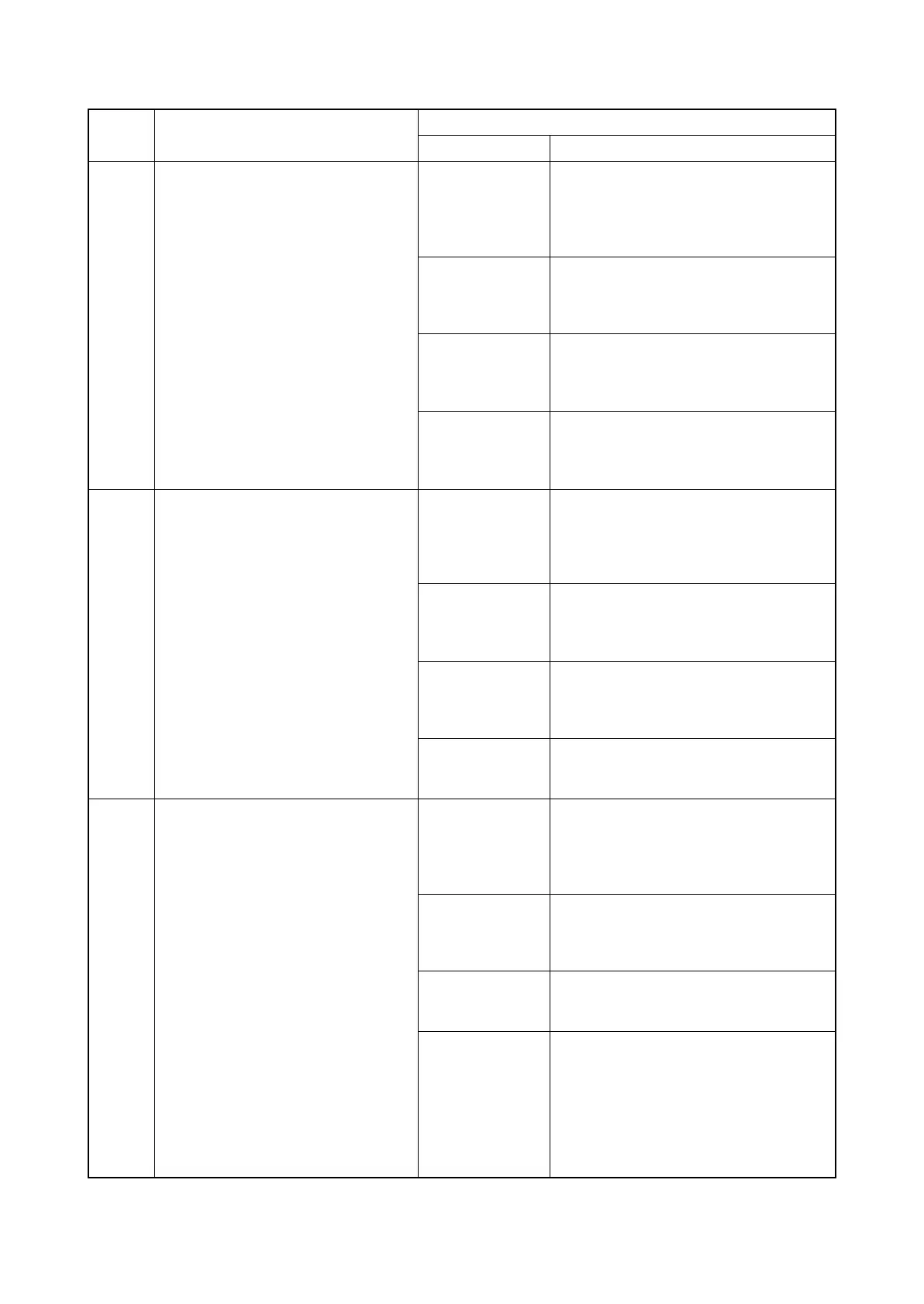

2KA

1-4-34

C2400 Eject motor error

After the motor drive ON signal is output

and 2 s elapses, the rated speed reach

signal is not input continuously for 1 s.

Poor contact in the

connector termi-

nals.

Check the connection of connector YC25 on

the engine PWB and the connector on the

eject motor, and the continuity across the

connector terminals. Repair or replace if

necessary.

Defective drive

transmission sys-

tem.

Check if the rollers and gears rotate

smoothly. If not, grease the bushings and

gears. Check for broken gears and replace if

any.

Defective eject

motor.

Run maintenance item U030 and check if

the eject motor operates when YC25-A5

(remote signal) on the engine PWB goes

low. If not, replace the eject motor.

Defective engine

PWB.

Run maintenance item U030 and check if

YC25-A5 (remote signal) on the engine

PWB goes low. If not, replace the engine

PWB.

C2500 MP motor error

After the motor drive ON signal is output

and 2 s elapses, the rated speed reach

signal is not input continuously for 1 s.

Poor contact in the

connector termi-

nals.

Check the connection of connector YC24 on

the engine PWB and the connector on the

MP motor, and the continuity across the con-

nector terminals. Repair or replace if neces-

sary.

Defective drive

transmission sys-

tem.

Check if the rollers and gears rotate

smoothly. If not, grease the bushings and

gears. Check for broken gears and replace if

any.

Defective MP

motor.

Run maintenance item U030 and check if

the MP motor operates when YC24-2

(remote signal) on the engine PWB goes

low. If not, replace the MP motor.

Defective engine

PWB.

Run maintenance item U030 and check if

YC24-3 (remote signal) on the engine PWB

goes low. If not, replace the engine PWB.

C2550 Paper conveying motor error

After the motor drive ON signal is output

and 2 s elapses, the rated speed reach

signal is not input continuously for 1 s.

Poor contact in the

connector termi-

nals.

Check the connection of connector YC2 on

the feed PWB and the connector on the

paper conveying motor, and the continuity

across the connector terminals. Repair or

replace if necessary.

Defective drive

transmission sys-

tem.

Check if the rollers and gears rotate

smoothly. If not, grease the bushings and

gears. Check for broken gears and replace if

any.

Defective paper

conveying motor.

Run maintenance item U030 and check if

the motor operates. If not, replace the paper

conveying motor.

Defective PWB. Replace the feed PWB or engine PWB and

check for correct operation.

Code Contents

Remarks

Causes Check procedures/corrective measures

Loading...

Loading...