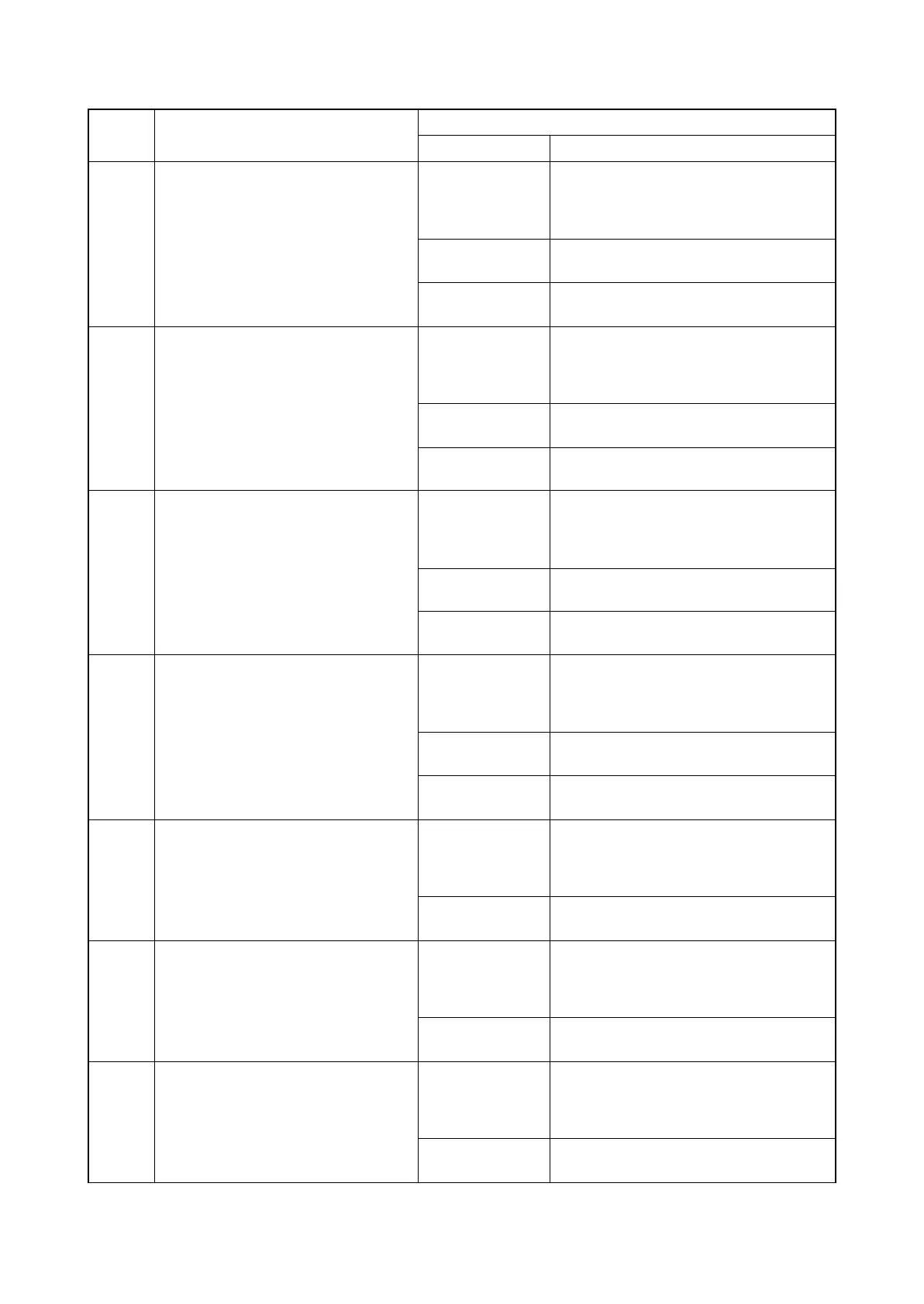

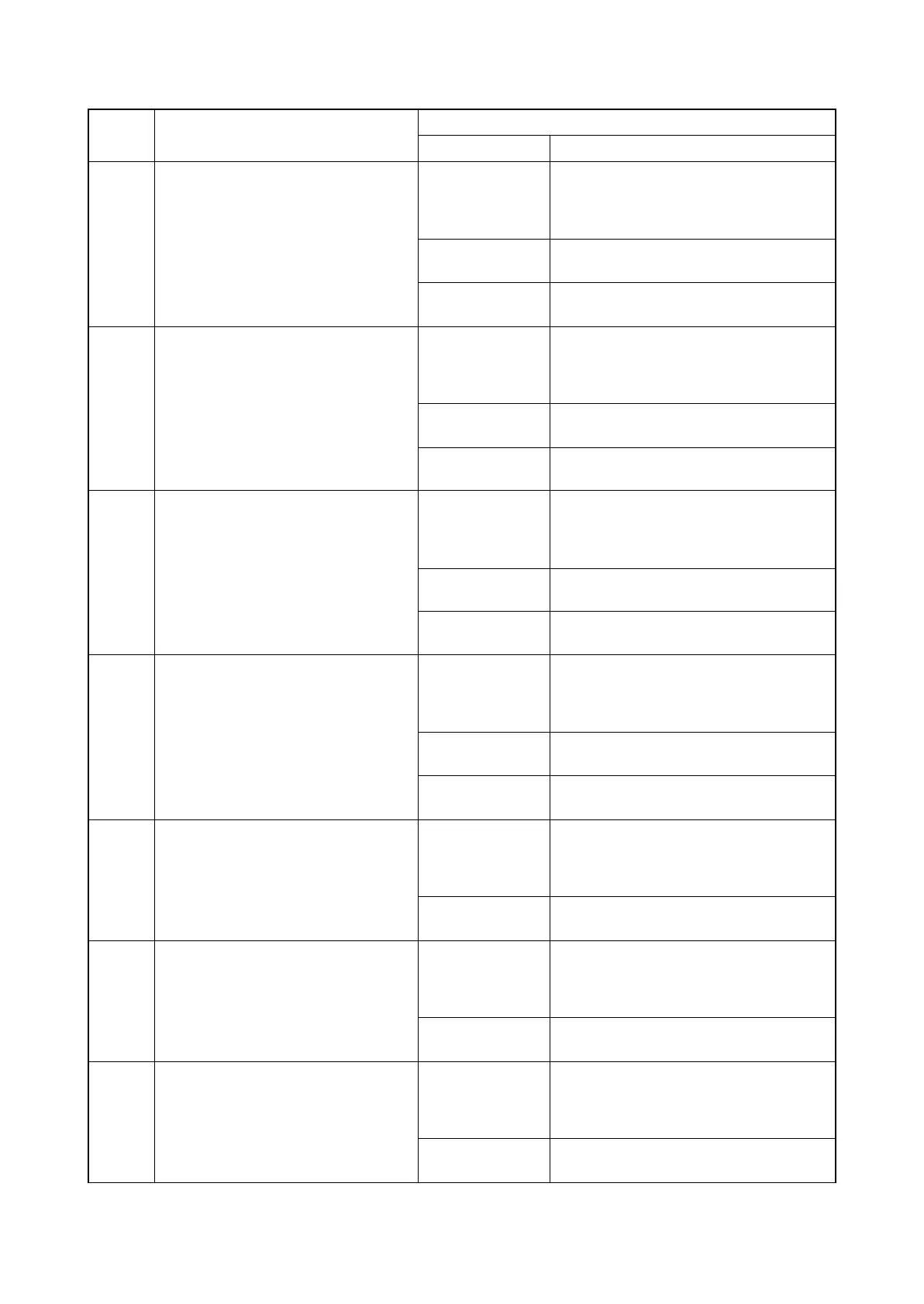

2KA

1-4-36

C4000 Polygon motor synchronization prob-

lem

The rated speed achievement signal

won’t turn to L in 48 s since the polygon

motor is activated.

Poor contact in the

connector termi-

nals.

Check the connection of connector YC13 on

the engine PWB and laser scanner unit, and

the continuity across the connector termi-

nals. Repair or replace if necessary.

Defective polygon

motor.

Replace the laser scanner unit (see page 1-

5-11).

Defective engine

PWB.

Replace the engine PWB and check for cor-

rect operation.

C4010 Polygon motor steady-state problem

The rated speed achievement signal

turns to H every other 24 s after the poly-

gon motor is stabilized.

Poor contact in the

connector termi-

nals.

Check the connection of connector YC13 on

the engine PWB and laser scanner unit, and

the continuity across the connector termi-

nals. Repair or replace if necessary.

Defective polygon

motor.

Replace the laser scanner unit (see page 1-

5-11).

Defective engine

PWB.

Replace the engine PWB and check for cor-

rect operation.

C4100 BD initialization problem

When power is turned on, ASIC of

engine PWB detects a BD error for 1 s

after the polygon motor is activated.

Poor contact in the

connector termi-

nals.

Check the connection of connector YC13 on

the engine PWB and laser scanner unit, and

the continuity across the connector termi-

nals. Repair or replace if necessary.

Defective laser

scanner unit.

Replace the laser scanner unit (see page 1-

5-11).

Defective engine

PWB.

Replace the engine PWB and check for cor-

rect operation.

C4200 BD steady-state problem Poor contact in the

connector termi-

nals.

Check the connection of connector YC13 on

the engine PWB and laser scanner unit, and

the continuity across the connector termi-

nals. Repair or replace if necessary.

Defective laser

scanner unit.

Replace the laser scanner unit (see page 1-

5-11).

Defective engine

PWB.

Replace the engine PWB and check for cor-

rect operation.

C5101 Main high-voltage K error

Abnormality of charger roller K is

detected when Vpp adjustment.

Installation defec-

tiveness on

charger roller unit

K.

Check the mounting state of the charger

roller unit K. If any problem is found, repair

or replace the unit.

Defective charger

roller unit K.

Replace the charger roller unit K (see page

1-5-27).

C5102 Main high-voltage C error

Abnormality of charger roller C is

detected when Vpp adjustment.

Installation defec-

tiveness on

charger roller unit

C.

Check the mounting state of the charger

roller unit C. If any problem is found, repair

or replace the unit.

Defective charger

roller unit C.

Replace the charger roller unit C (see page

1-5-27).

C5103 Main high-voltage M error

Abnormality of charger roller M is

detected when Vpp adjustment.

In

st

allation defec-

tiveness on

charger roller unit

M.

Check the mounting state of the charger

roller unit M. If any problem is found, repair

or replace the unit.

Defective charger

roller unit M.

Replace the charger roller unit M (see page

1-5-27).

Code Contents

Remarks

Causes Check procedures/corrective measures

Loading...

Loading...