44 BA052301-en

3.2.2 Exhaust Suction System

The exhaust quantity depends upon the test vehicle.The factors which are most influential are

the engine cubic capacity and RPM as well as the combustion process (spark or compression

ignition).

As a safety precaution it is recommended that a CO warning device be installed in the test

room.

Equation for dimensioning of exhaust suction systems (see also TRGS 554, section 4.7.4.3,

paragraph 2).

V = V

h

x n x 0.0363 x 1.2

V = necessary suction volume flow (m³/h)

V

h

= cubic capacity of the test vehicle (l)

n = engine speed of the test vehicle (rpm)

0.0363 = approximate value

1.2 = fresh air share of 20 %

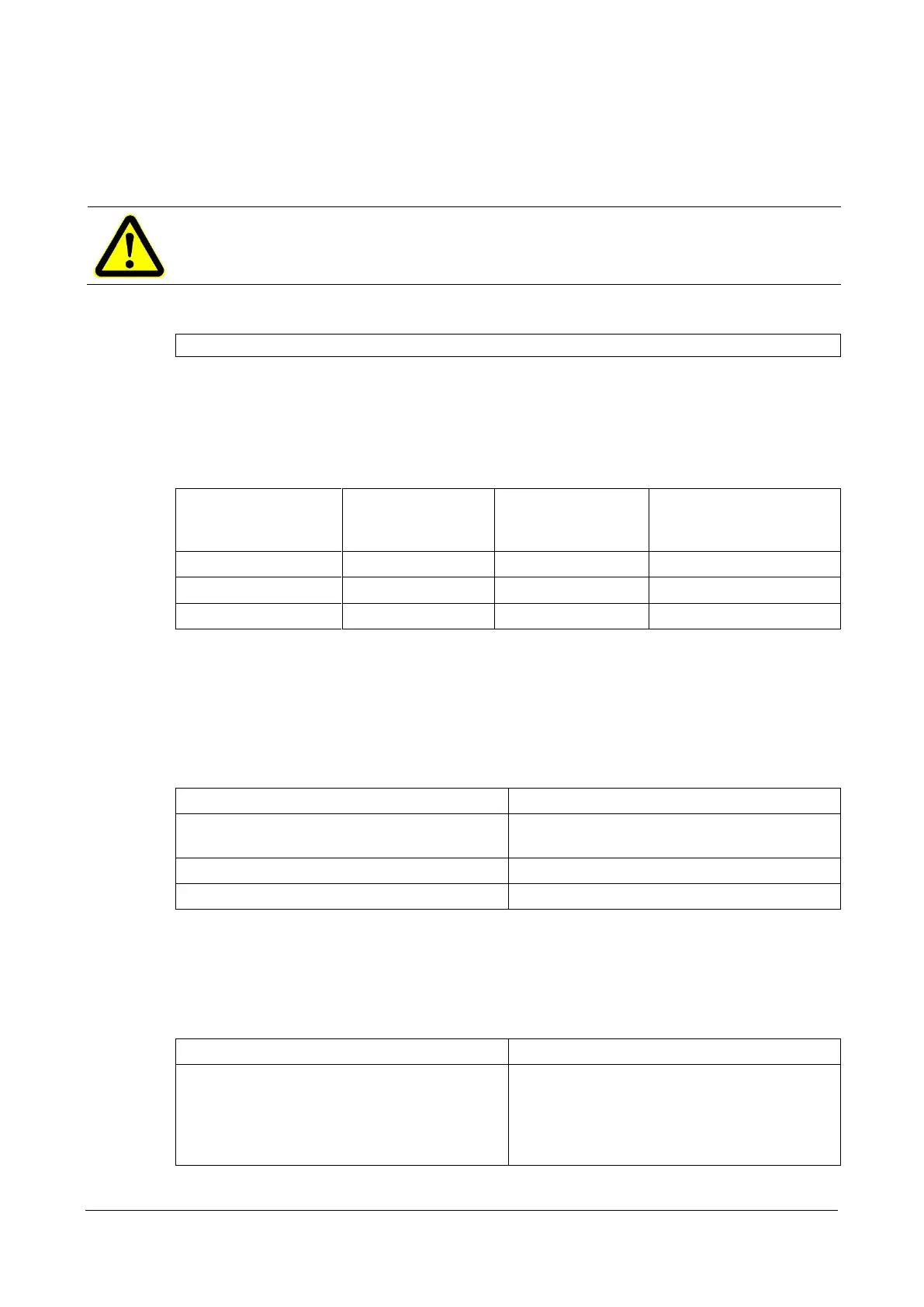

Experimental values based on BG-BIA / ASA-recommendations *:

Car workshop

Service/Repair

Car workshop

Test room + AU

Truck workshop

Service/Repair

Truck workshop

Test room + Emission

test

* Measurement point: Interface recording element-exhaust hose

Pay attention to temperature consistency. The respective exhaust suction system must be

adapted to the needs of the operator.

It is recommended that the exhaust suction system not be combined with a welding smoke

suction system and then connected to a ventilator. It is possible that a combustible or explosive

mixture may be created based (see ZH 1/454 vehicle maintenance guideline).

Example for calculation based on the equation V = V

h

x n x 0.0363 x 1,2

Car with 3.0 liter cubic capacity, service work

with average speed of 3000 rpm

TRUCK 12.0 Liter cubic capacity, service work

with average speed of 1500 rpm

V = 3.0 x 3000 x 0. 0363 x 1.2

V = 12.0 x 1500 x 0. 0363 x 1.2

The exhaust discharge for the auto exhaust can be done with suction hoses (air flow rate

> 3000 m³/h) or with suction flaps (air flow rate approx. 10000 m³/h) .

Example for calulation at dynamometers V

t

= V

h

x (t in °C:273 Kelvin) x

= Supply degree of 0.85 (without Turbocharger)…approx. 1.9 (depending on engine and

manufacturer)

Car dyno,

Engine 5.547 liter,

Engine speed 5000 rpm,

Temperature 500°C,

= 1.0

Truck dyno,

Engine 18.273 liter,

Engine speed 2300 rpm,

Temperature 500 °C,

= 1.5

Loading...

Loading...