Manitowoc Published 03-29-17, Control # 064-23 3-69

14000 OPERATOR MANUAL OPERATING CONTROLS AND PROCEDURES

Control Calibration

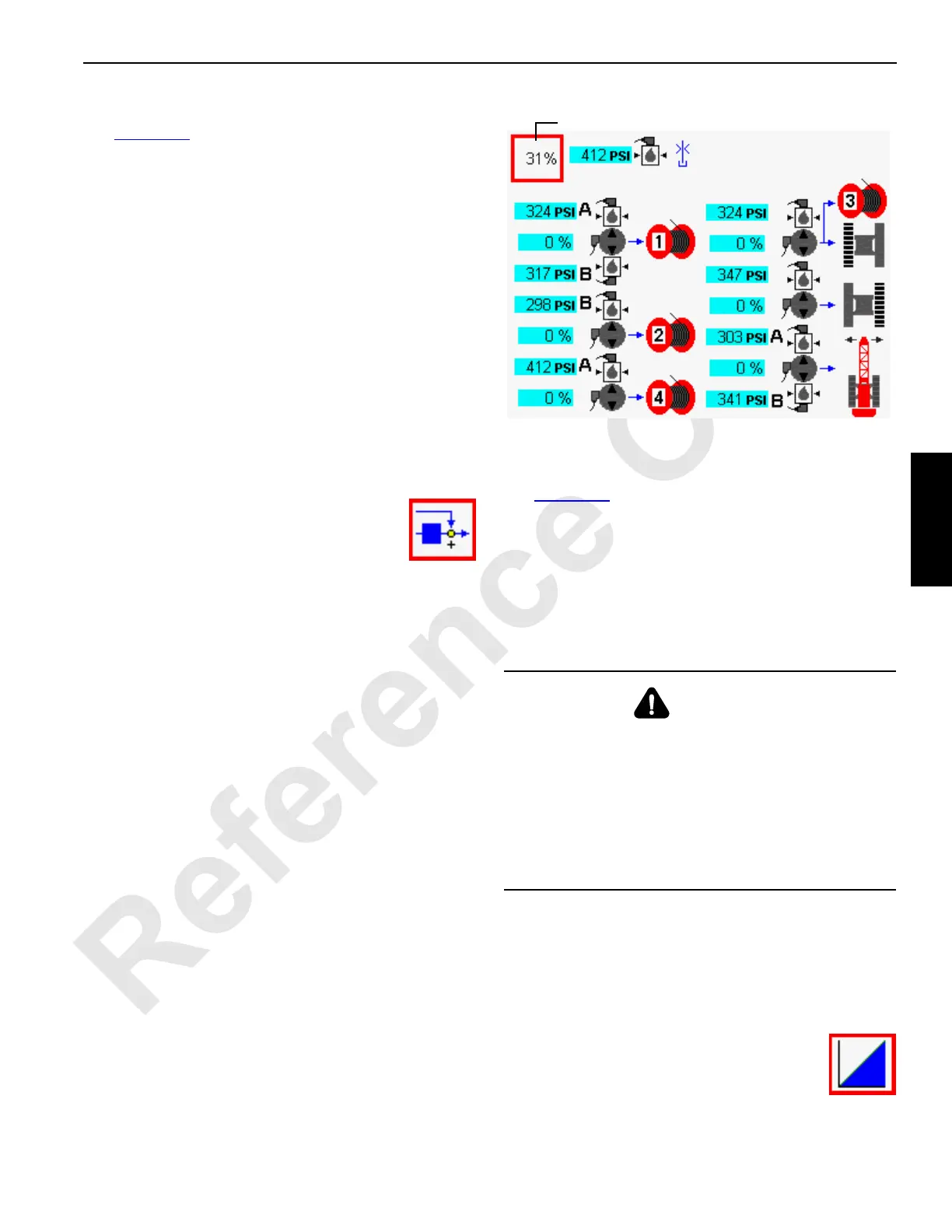

See Figure 3-68 for the following procedure.

Control calibration calculates pump threshold command

level for all drum and swing functions.

Perform this calibration when:

- A new pump or motor is installed in a drum or swing

- A new master node or software is installed

- Operation indicates threshold is in error

- Excessive handle motion or time required to

initiate motion

- Inability to smooth start motion

Calibrate controls as follows:

1. Apply all park brakes with switches on control console.

2. Start and run engine at high idle.

3. Press Enter button to go to Pressure Test and

Calibration screen from Menu screen.

4. Press Enter button to go to level 2. Use

Select buttons to show CONTROL

CALIBRATION icon in data box.

5. Press Confirm button to start test.

6. Calibration starts and percent of completion is displayed

in data box.

7. When calibration is complete, control calibration icon

reappears in data box.

Pump threshold command levels must be within a

specified range during this test. Any pump requiring a

threshold command level outside this range is

highlighted yellow. Troubleshoot failed circuit to

determine cause of fault.

High Pressure Test

See Figure 3-69 for the following procedure.

The high pressure test checks ability of all primary crane

functions to reach and hold high pressure. This test generally

is used only as a shop procedure on new cranes. It can also

be used as a quick way to test hydraulic components in

primary hydraulic circuits.

CAUTION: Only perform this high pressure test when

absolutely necessary and by a qualified service technician.

Test high pressure as follows:

1. Apply all park brakes with switches on control console.

2. Start and run engine at high idle.

3. Press Enter button to go to Pressure Test and

Calibration screen from Menu screen.

4. Press Enter button to go to level 2. Use

Select buttons to show HIGH PRESSURE

icon in data box.

5. Press Confirm button to start test.

WARNING

High Pressure Hazard!

This test generates maximum pressure in the main

hydraulic circuits. Defective brakes may allow unintended

motion during test. Move crane to an area where such

motion is not a hazard.

We recommend an observer to monitor functions the

operator cannot see.

Be prepared to stop engine if unintended motion occurs.

FIGURE 3-68

14COM3-52

Data BoxData BoxData Box

Loading...

Loading...