Manitowoc Published 03-29-17, Control # 064-23 v2 4-3

14000 OPERATOR MANUAL SETUP AND INSTALLATION

SELF-ERECTING EQUIPMENT

The 14000 is equipped with the following self-erect

components for assembly and disassembly (see Figure 4-1

):

• Carbody jacks with pads for lifting the crane onto and off

a trailer. The jacks are controlled by handles on front of

the carbody.

• Hydraulically actuated pins for connecting and

disconnecting the crawlers to and from the carbody. The

pins are controlled by handles on front of the carbody.

• Hydraulic cylinders for raising and lowering the gantry.

The cylinders are controlled by switches on a remote

control.

• Hydraulically actuated pins for engaging and

disengaging the gantry backhitch pins. The pins are

controlled by switches on a remote control.

• Hydraulically actuated mast arms for raising the mast to

the operating position and lowering it to the transport

position. The arms are controlled by a switch on the

overhead console in the operator’s cab.

• Mast which can be used as a boom to handle the crane’s

crawlers and counterweights and to assemble and

disassemble the boom and jib. The mast is controlled by

the boom hoist control handle in the operator’s cab

• Hydraulically actuated pins for connecting the boom butt

to the rotating bed. The pins are controlled by a switch

on the overhead console in the operator’s cab.

• Assembly block — 30 USt (27 t) — and 4-leg chain sling

with hooks for handling components

ASSEMBLY AND DISASSEMBLY NOTES

The crane, boom, and jib shall be assembled and

disassembled by experienced personnel trained in erection

and operation of construction cranes.

Before attempting to assemble, operate, or disassemble the

crane, read and become thoroughly familiar with the

instructions in this section and in the boom and jib assembly

drawings at end of this section.

Contact your Manitowoc dealer for assistance if any

procedure is not fully understood.

ASSEMBLY AND DISASSEMBLY AREA

Select an assembly/disassembly area that has a firm, level,

uniformly supporting surface. Make sure the area is large

enough to accommodate the crane and the selected boom

length, movement of trucks with trailers, and movement of an

assist crane (if used).

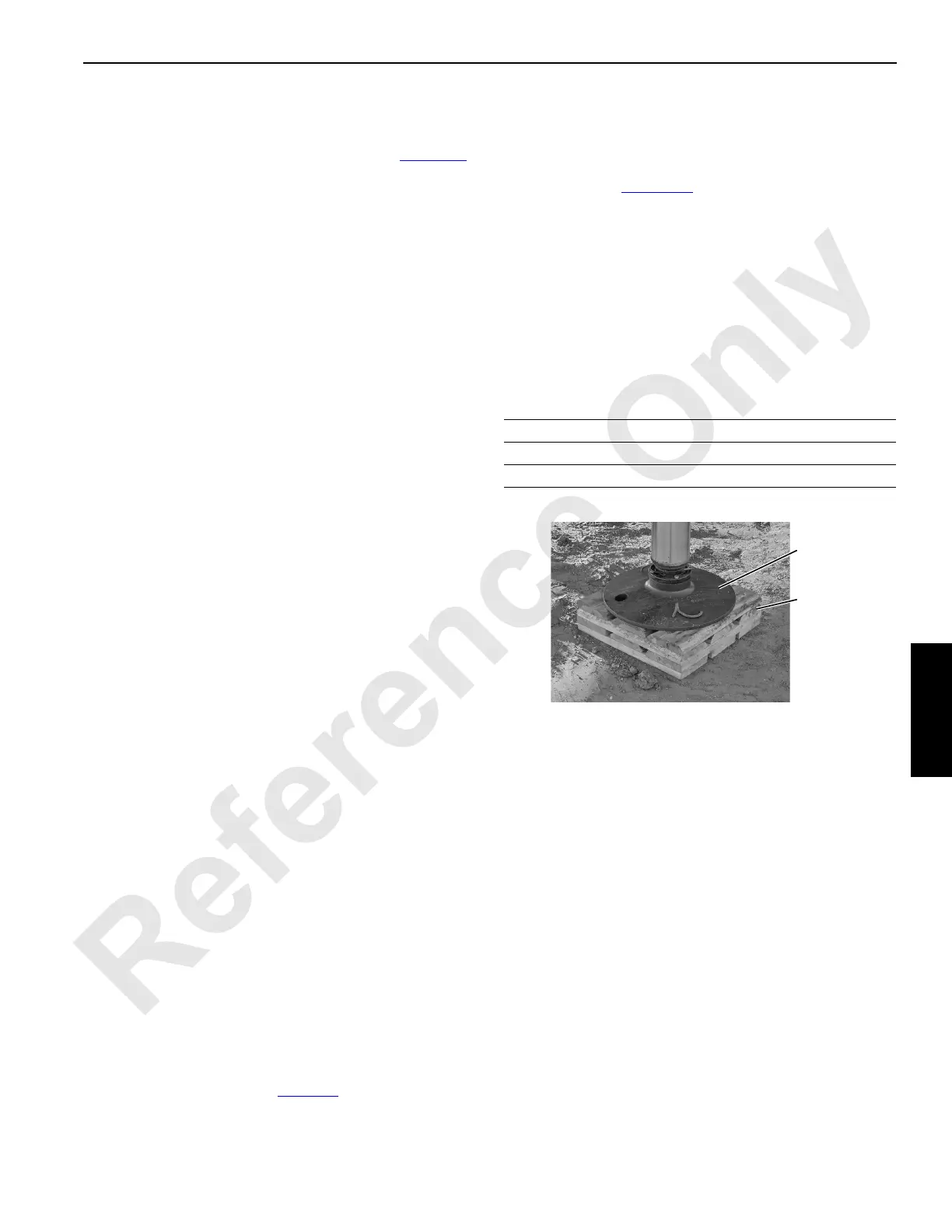

Set the jack pads on a flat, firm foundation that will support

the load placed on them. See Table 4-1

for loadings.

Do not set the jack pads in holes, on rocky ground, or on

extremely soft ground. Jack pads could break.

If necessary, use wood blocking or steel plates under the

jack pads to properly distribute loading and to provide a

smooth surface (Figure 4-2

). The wood blocking or steel

plates must be:

• Free of defects

• Strong enough to prevent being crushed or bent

• Of sufficient length and width to prevent settling under

load

Contact your Manitowoc dealer for ground bearing

information.

Table 4-1

Load Data for Carbody Jacks

ACCESSING PARTS

Some parts of the crane, boom, and jib cannot be reached

from the ground. Take necessary precautions to prevent

slipping and/or falling off the crane or boom during assembly

disassembly, maintenance, or other work. Falling from any

height could result in serious injury or death.

Owner/user must provide workers with approved ladders or

aerial work platforms to access those areas of the crane,

mast, boom, and jib that cannot be reached from ground or

from steps, ladders, catwalks, and platforms provided by

Manitowoc.

Adhere to local, state, and federal regulations for handling

personnel and for personnel fall protection.

Do not use top of mast, boom inserts, and boom top as

walkways.

Catwalks and platforms are provided on the boom butt for

accessing the boom butt wire rope guide.

Maximum Load on each Jack — 72,000 (32 659 kg)

Jack Pad Diameter —24 in (610 mm)

Jack Pad Weight — 50 lb (23 kg)

Jack Pad

Blocking

P2474

FIGURE 4-2

Loading...

Loading...