Maintenance overview

5.2 Maintenance plans

07.12.2017

Maintenance manual 3 302 649 en 5 - 15

GMK4090

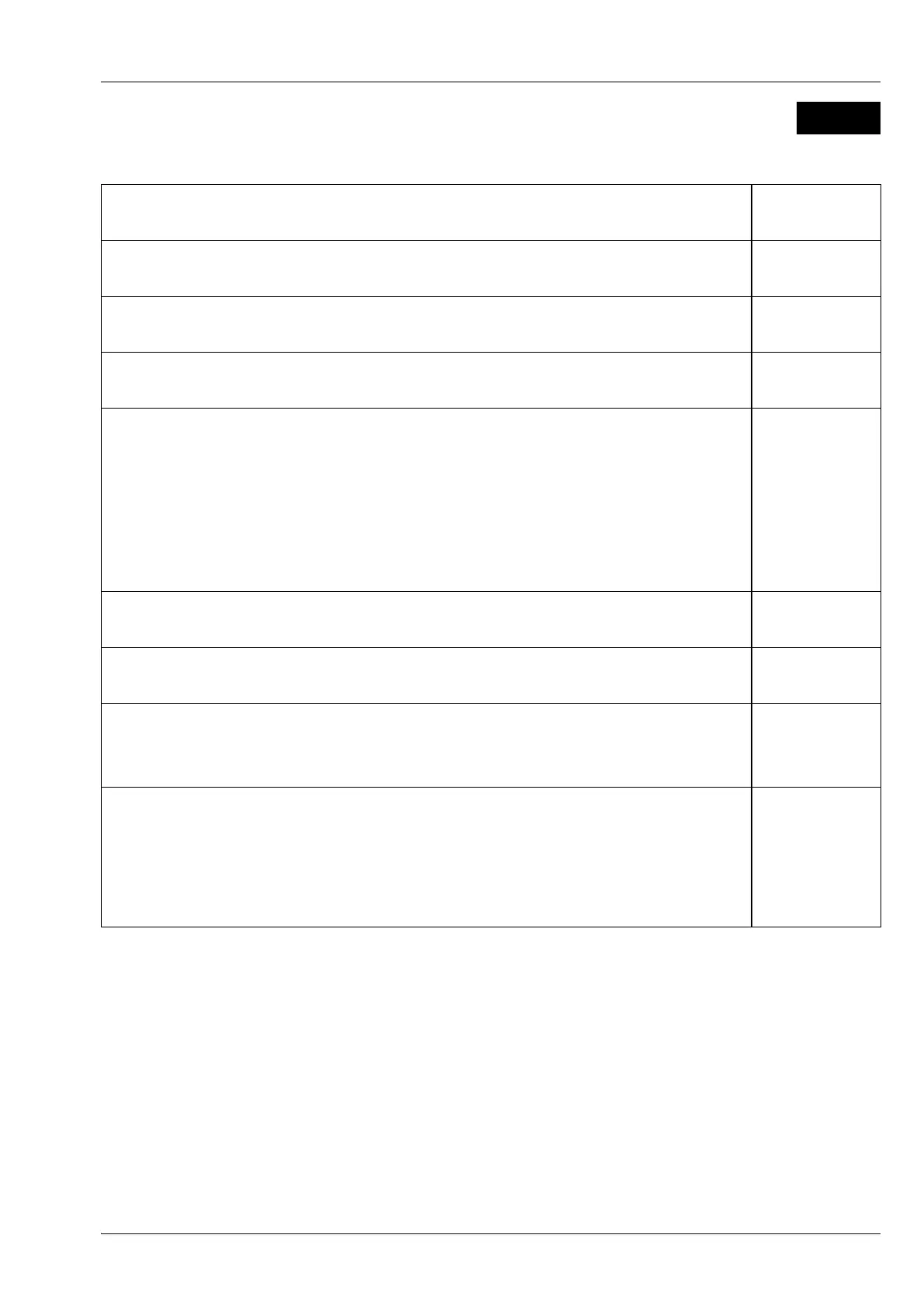

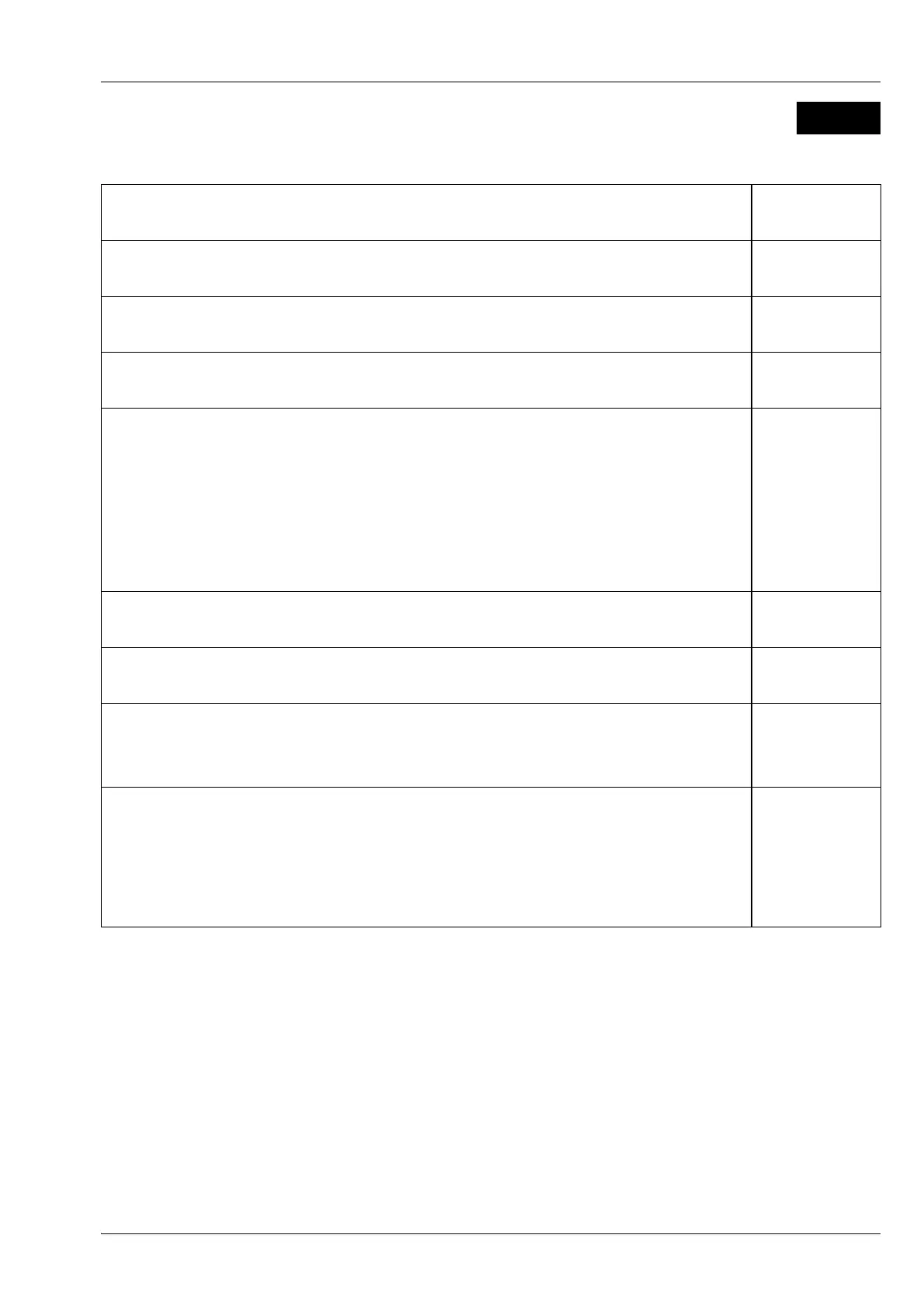

Maintenance work on the SUPERSTRUCTURE:

Every twelve months / after 1,000 oper. hrs.

Hoists

– Changing the oil/checking the oil à p. 8 - 11

Slewing gear

– Changing the oil/checking the oil à p. 8 - 19

Slewing bearing

– Lubricating the locking of turntable à p. 8 - 30

Hydraulic system

– Changing the ventilation filter à p. 8 - 36

– Pressure accumulator – checking the gas pressure à p. 8 - 37

– Taking oil samples:

depending on the oil sample test results:

– Changing the hydraulic oil

à p. 8 - 37

à p. 8 - 42

– Changing the hydraulic oil filter à p. 8 - 39

Main boom

– Checking the locking system à p. 8 - 50

Hook blocks

– Lubricating hook blocks à p. 8 - 69

Air conditioning system

– Checking the entire air conditioning system à p. 8 - 76

– Changing the pollen filter à p. 8 - 78

Other maintenance work

– Lubricating the crane cab door à p. 8 - 81

– Lubricating the step à p. 8 - 82

– Lubricating the connecting and socket pins à p. 8 - 83

– Renewing the corrosion protection à p. 8 - 84

Loading...

Loading...