sent.

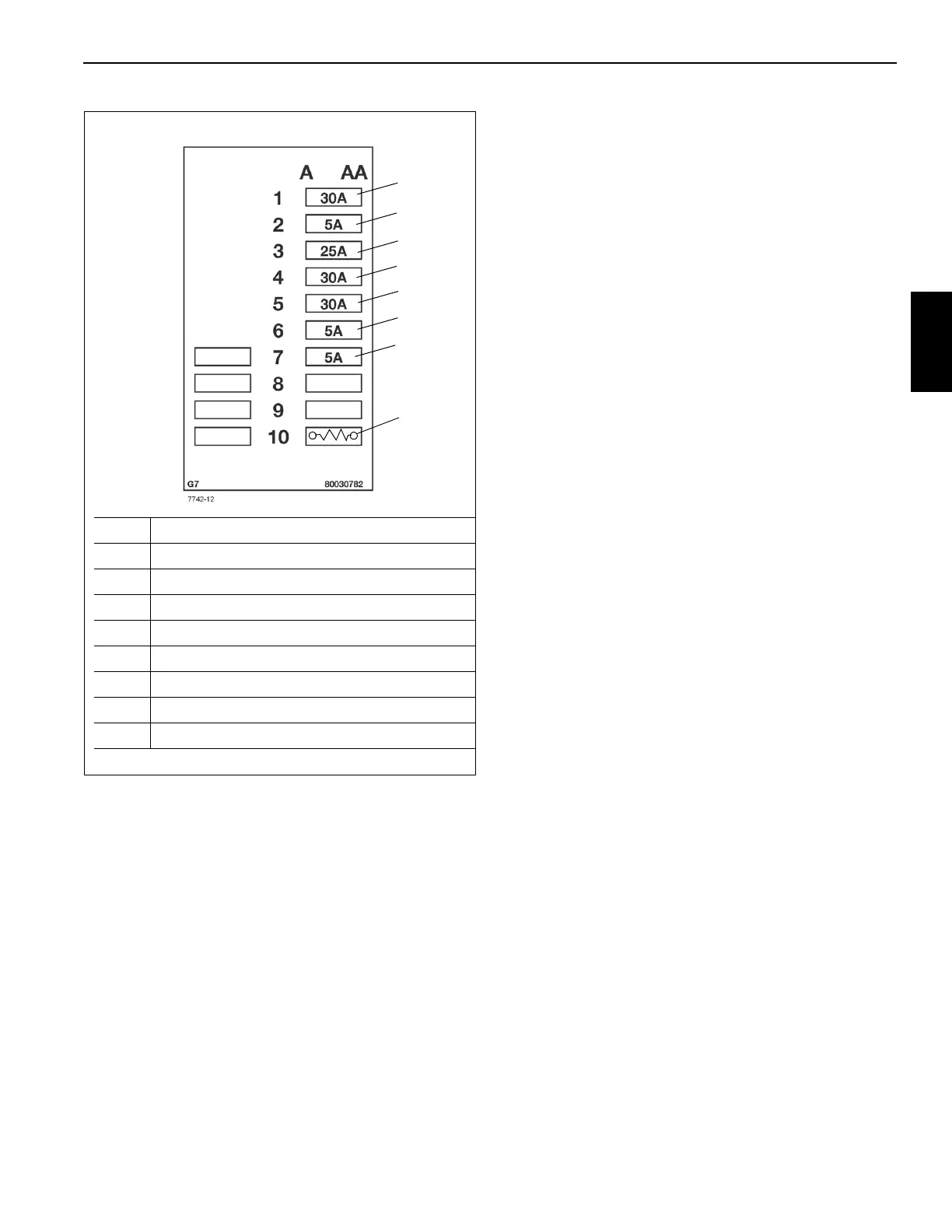

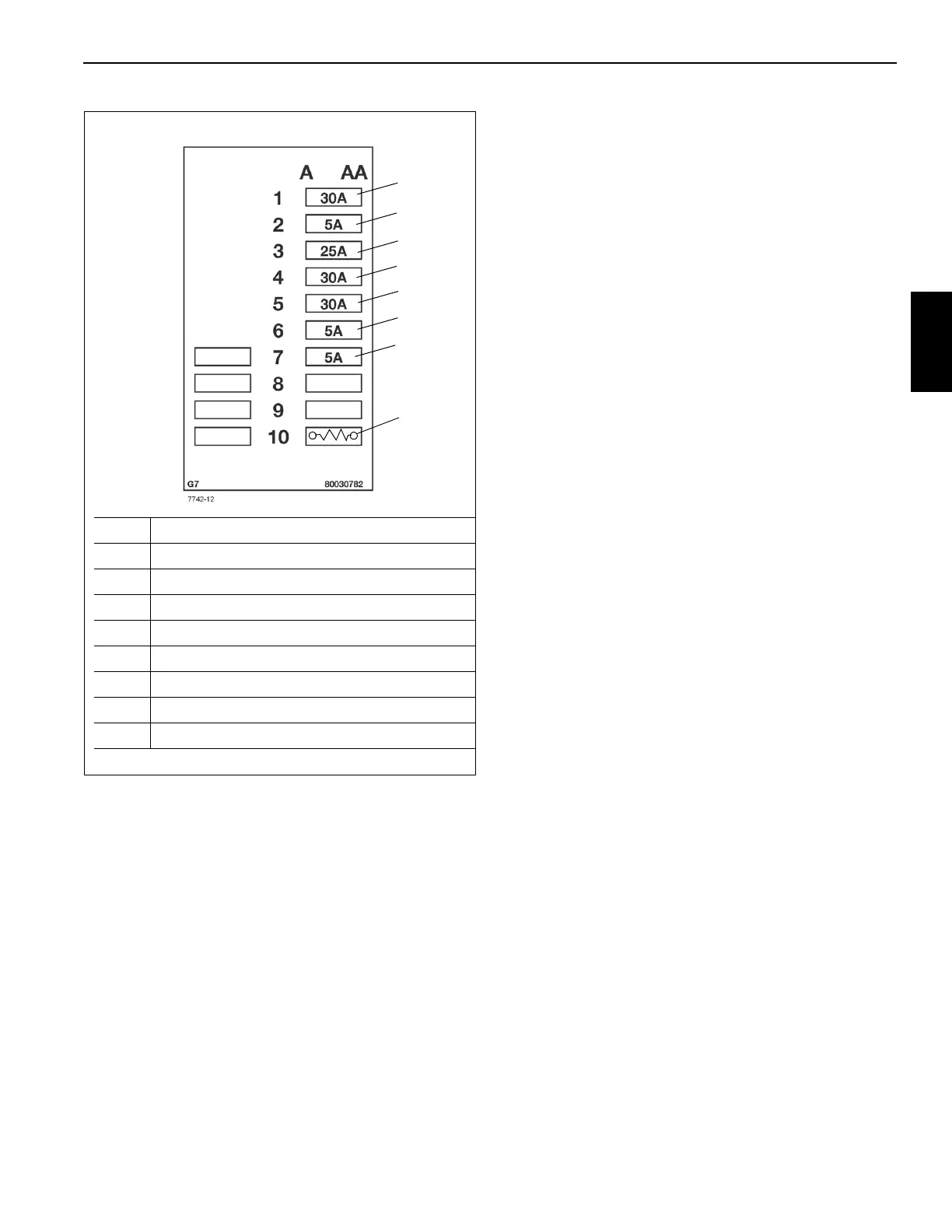

FIGURE 3-6

5

6

7

10

4

3

2

1

Item Description

1 ECM, 30 Amp Fuse (F1)

2 Swivel, 5 Amp Fuse (F2)

3 Carrier, Center Module, 25 Amp Fuse (F3)

4 Carrier, Center Module, 30 Amp Fuse (F4)

5 Carrier, Front Module, 30 Amp Fuse (F5)

6 Diagnostic Connector, 5 Amp Fuse (F6)

7 Power Control Relay, 5 Amp Fuse (F7)

10 120 Ohm Resistor, Starter Lockout Circuit

Loading...

Loading...