3030226 Rev. D 2-14 Installation And

Initial System Start-Up

3. Operate the RO with product line connected between the product and return

ports on the RO and waste flow to drain for at least 15 minutes (minimum 30

minutes for new machine or after membrane replacement), after the product

water quality has stabilized and before drawing the water sample.

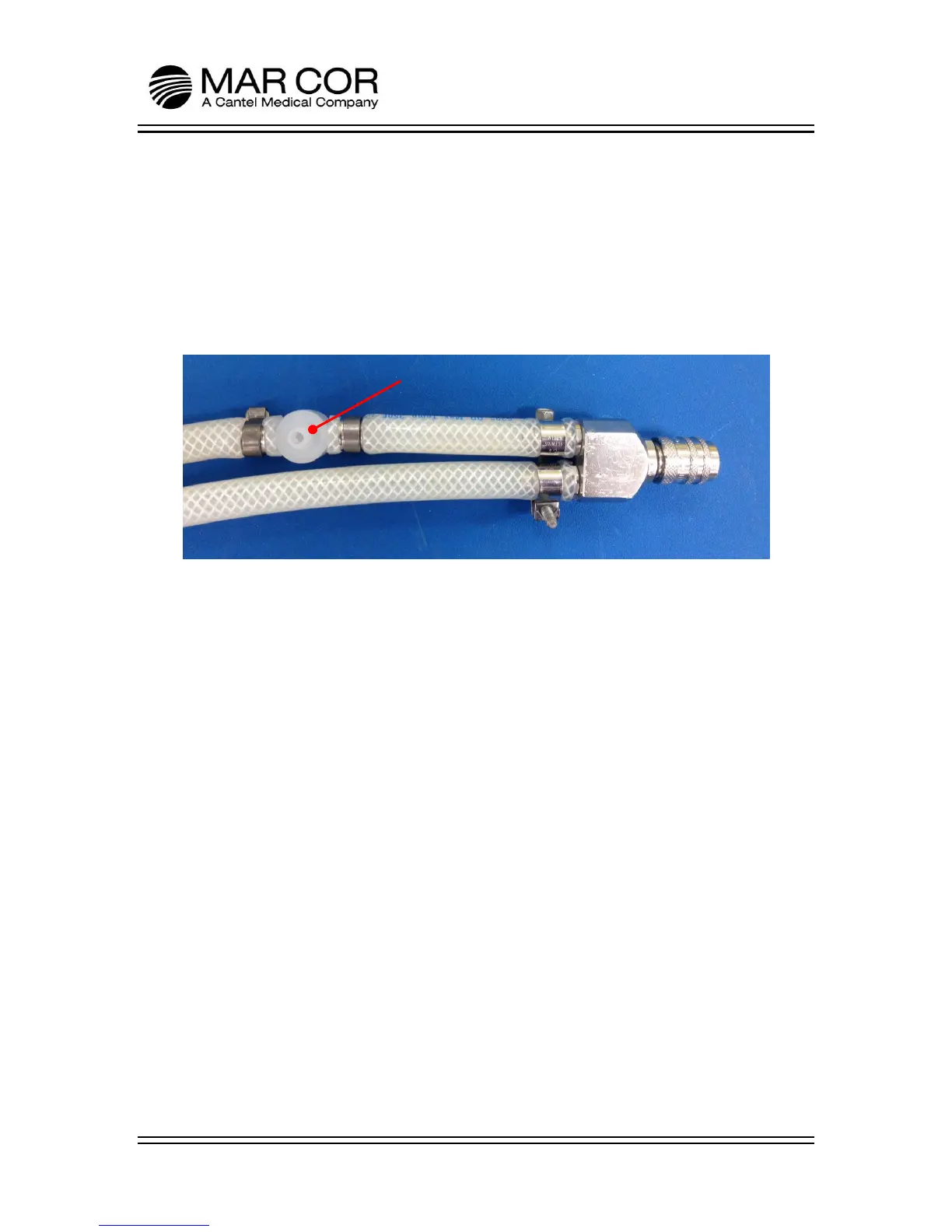

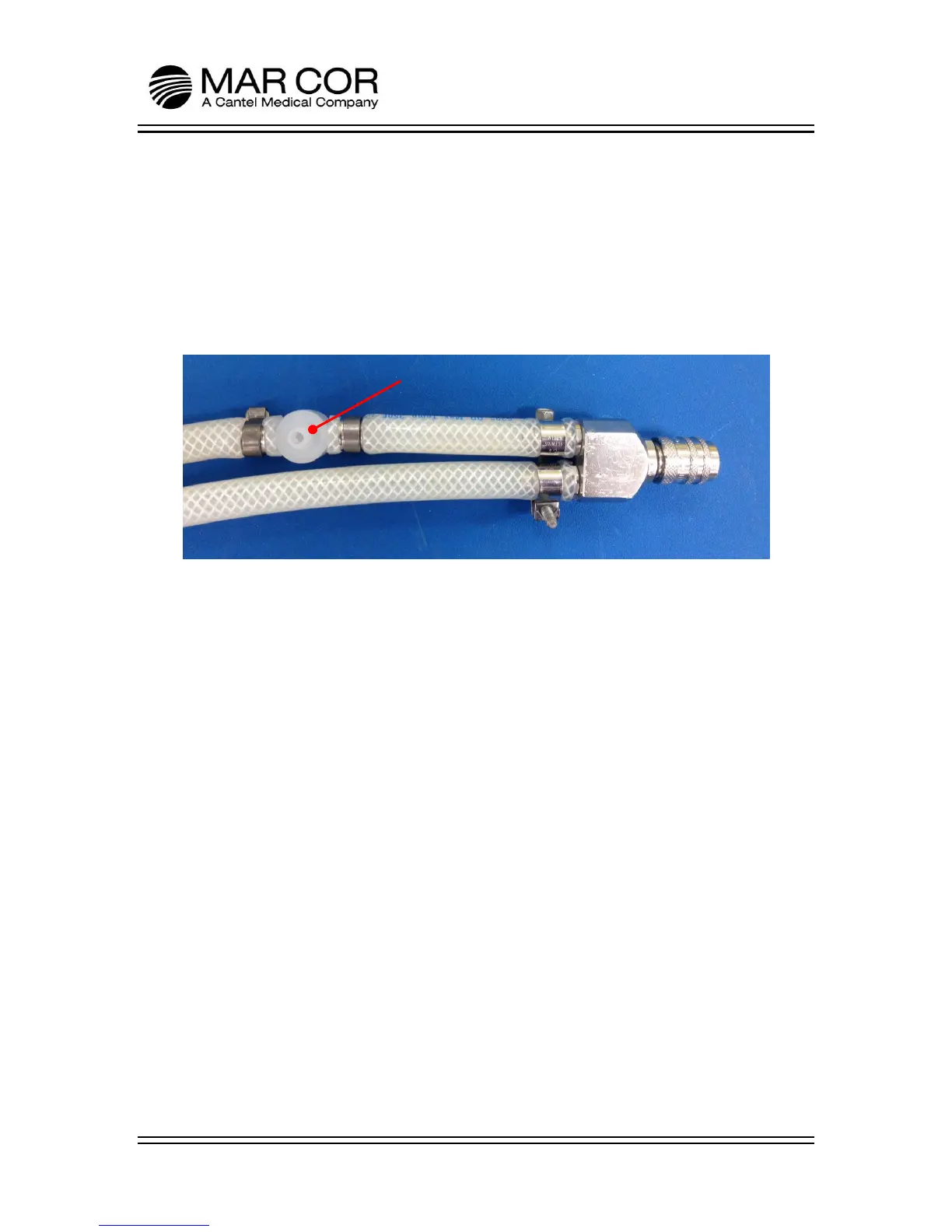

4. Using alcohol, wipe the sample port and allow to air dry. Using aseptic

technique, insert the male luer end of the first sterile/pyrogen free syringe into

the port, withdraw the syringe plunger to the maximum sample volume.

Remove and discard the syringe.

5. Using the second sterile/pyrogen free syringe draw a sample by inserting the

male luer end into the port and withdraw the appropriate sample as required

for your laboratory. Aseptically transfer the sample to the lab supplied

container and cap the specimen container immediately.

6. Label the specimen appropriately with:

• Test to be performed - "AAMI"

• Sample source - product water/RO, machine serial number and room

location

• Time and date sample obtained

• Person who obtained specimen

• Any other pertinent information or procedures your facility or lab

requires

7. Fill out the laboratory requisition form. Ensure the requisition form has, at a

minimum, information to identify the facility or location of the RO, the serial

number or facility equipment number to ensure which RO was tested and the

name, phone number and address of whom to contact.

8. Place the bottle and the completed requisition in the pre-addressed mailer and

mail it directly to the laboratory.

Loading...

Loading...