2C-10 ELECTRICAL AND IGNITION 90-13645--2 1095

Carburetor Specifications

Carburetor number stamped at TOP of carburetor mounting flange

NOTE: Early model engines may have identification stamped on face of air box mounting flange.

Carb Number Location Model HP Main Jet* Bowl* Vent Jet

WME-11, 20- 1

2

3

Top Carburetor

Top Center Carburetor

Bottom Center Carburetor

Bottom Carburetor

100 .054 None

WME-14, 21- 1

2

3

Top Carburetor

Top Center Carburetor

Bottom Center Carburetor

Bottom Carburetor

115 .076 None

* Standard jets listed are for operation of engine from 0-762 m (0-2500 ft.) of elevation (see jet size chart).

INITIAL STARTING ADJUSTMENTS

NOTE: For adjusting carburetor throttle linkage and

synchronizing carburetors, see section “Timing/

Synchronizing/Adjusting” of this manual.

After service or replacement of carburetor, turn low

speed mixture screw adjustment in (clockwise) until it

seats lightly, then back off (each carburetor) to speci-

fications (100-1-3/4 turns or 115-1-1/2 turns). This will

permit engine start-up.

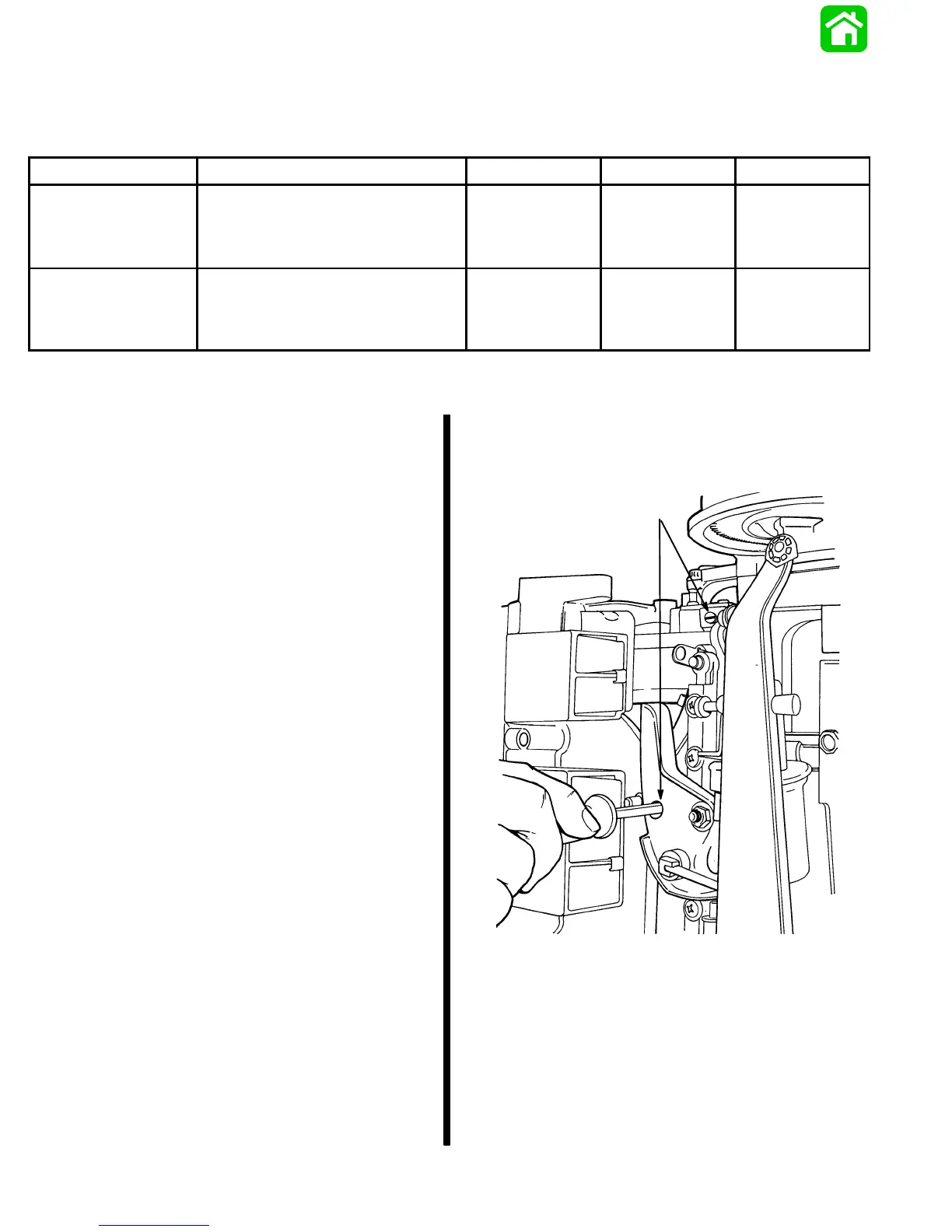

LOW SPEED MIXTURE ADJUSTMENTS

NOTE: Only the top two carburetors on four cylinder

models have an adjustable low speed mixture screw.

1. Start engine and allow to warm up (run for several

minutes). Throttle back to idle for about one min-

ute to allow RPM to stabilize.

2. With engine running at idle speed (in water) in

“Forward” gear (prop on), turn low speed mixture

screw, IN (clockwise) until engine starts to “bog”

down and misfire. Back out 1/4 turn or more.

3. Check for too lean mixture on acceleration.

4. DO NOT adjust leaner than necessary to attain

reasonable smooth idling. When in doubt, stay on

the slightly rich side of the adjustment.

22990

a

a - Low Speed Mixture Screw

Loading...

Loading...