6C-26 90-13645--2 495POWER-TRIM

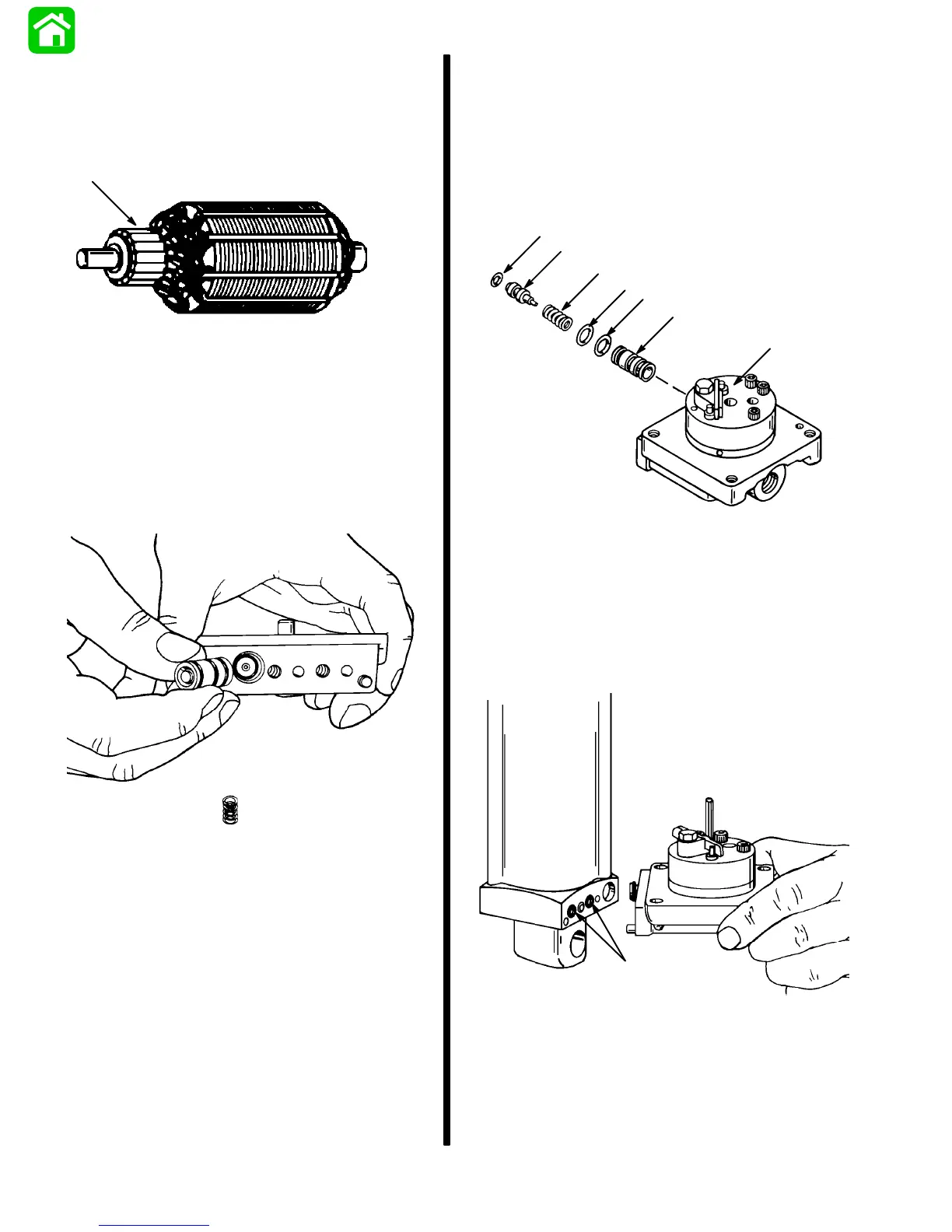

CHECKING AND CLEANING COMMUTATOR

If commutator is worn it can be turned down on an ar-

mature conditioner tool or on a lathe.

Clean commutator with “00” sandpaper.

a

a - Commutator

Power Trim System

Reassembly

Manifold Installation

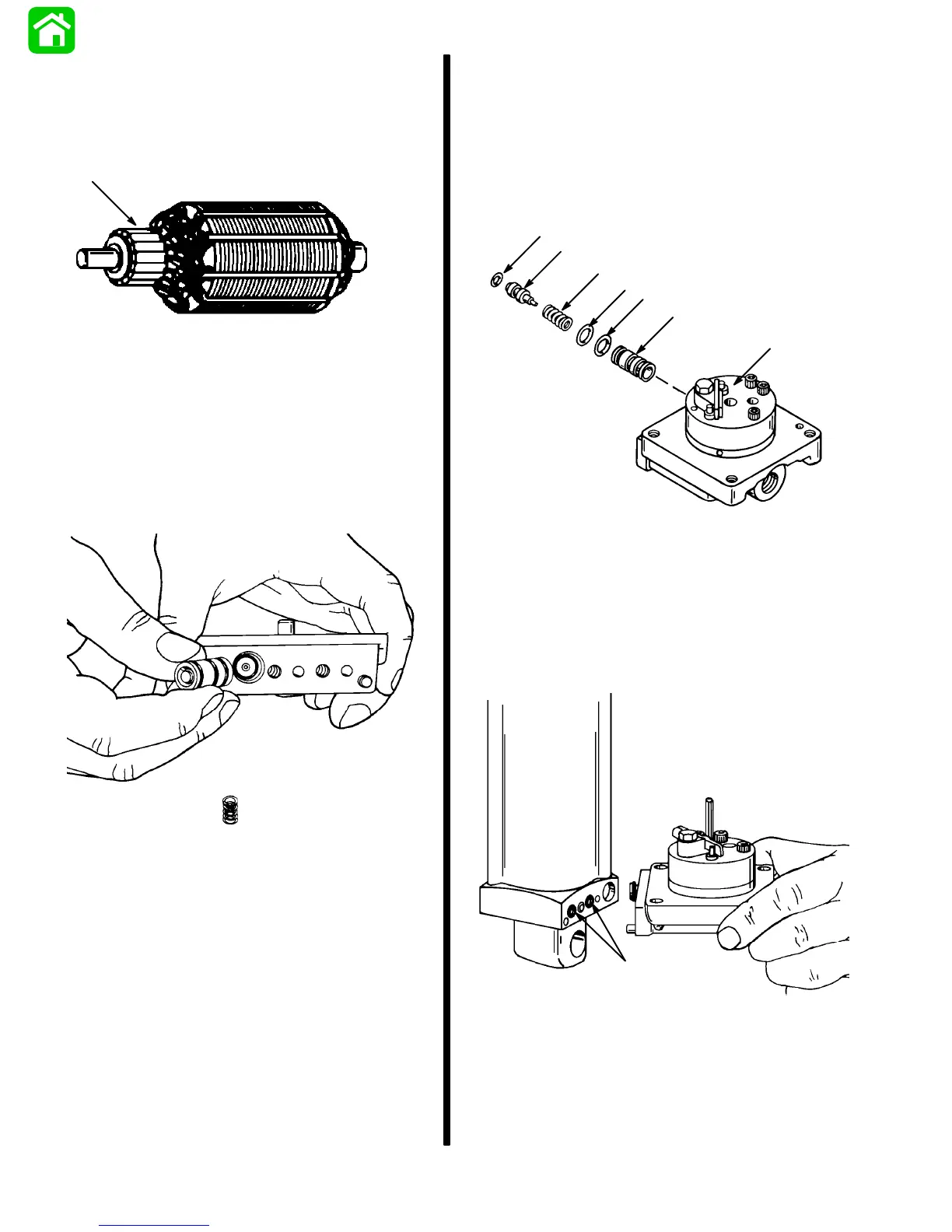

IMPORTANT: Install spring, check valve and

O-ring into manifold. Position components in

place using sleeve to seat in place.

50999

1. Install check valve components into pump man-

ifold.

IMPORTANT: Sleeve (d) is chamfered on I.D. on

end opposite drilled cross hole. Install spool (e)

(with O-ring installed) from chamfered end of

sleeve to avoid possibility of damaging O-ring on

spool.

51560

e

a

b

d

b

b

c

a - Manifold and Pump

b - O-ring (3)

c - Spring

d - Sleeve

e - Spool

2. Install O-rings on cylinder and secure manifold

assembly to cylinder using screws. Torque screws

to 100 lb. in. (11.3 N·m).

51486

a

a - O-ring (2)

Loading...

Loading...