must be set to any value in the opposite measuring direction. For example, for a test requiring load

holding at 10 lbF of compression force, set the upper set point to 30 lbF tension (as an example), and the

lower set point to 10 lbF compression.

If the CYCLING option has been enabled, load holding will be active for the period of time as defined in

the Dwell Time settings. If CYCLING has not been enabled, load holding will continue indefinitely.

5.8.1 Adjusting speed for sample stiffness variations

An appropriate speed should be chosen for a given sample. Fine tuning may be necessary to ensure

optimal crosshead dynamic behavior. Stiff samples require a lower test speed; softer samples can be

tested at higher speeds. If the speed of approach is too high for a given sample stiffness, the crosshead

may overshoot the set point value, requiring an adjustment sequence where the crosshead reverses, then

moves again in the original direction multiple times before settling at the set point value. A high enough

speed may cause this correction cycle to repeat indefinitely.

For softer samples the amplitude of oscillation will be smaller, but could still be present for the duration of

the load holding period. This is typical for samples which may relax, such as rubber, foam, etc. Lowering

the test speed will reduce the oscillation.

For minimally relaxing materials such as metal springs, the oscillation should stop shortly after the holding

force is reached.

Load holding may be interrupted at any time by pressing STOP.

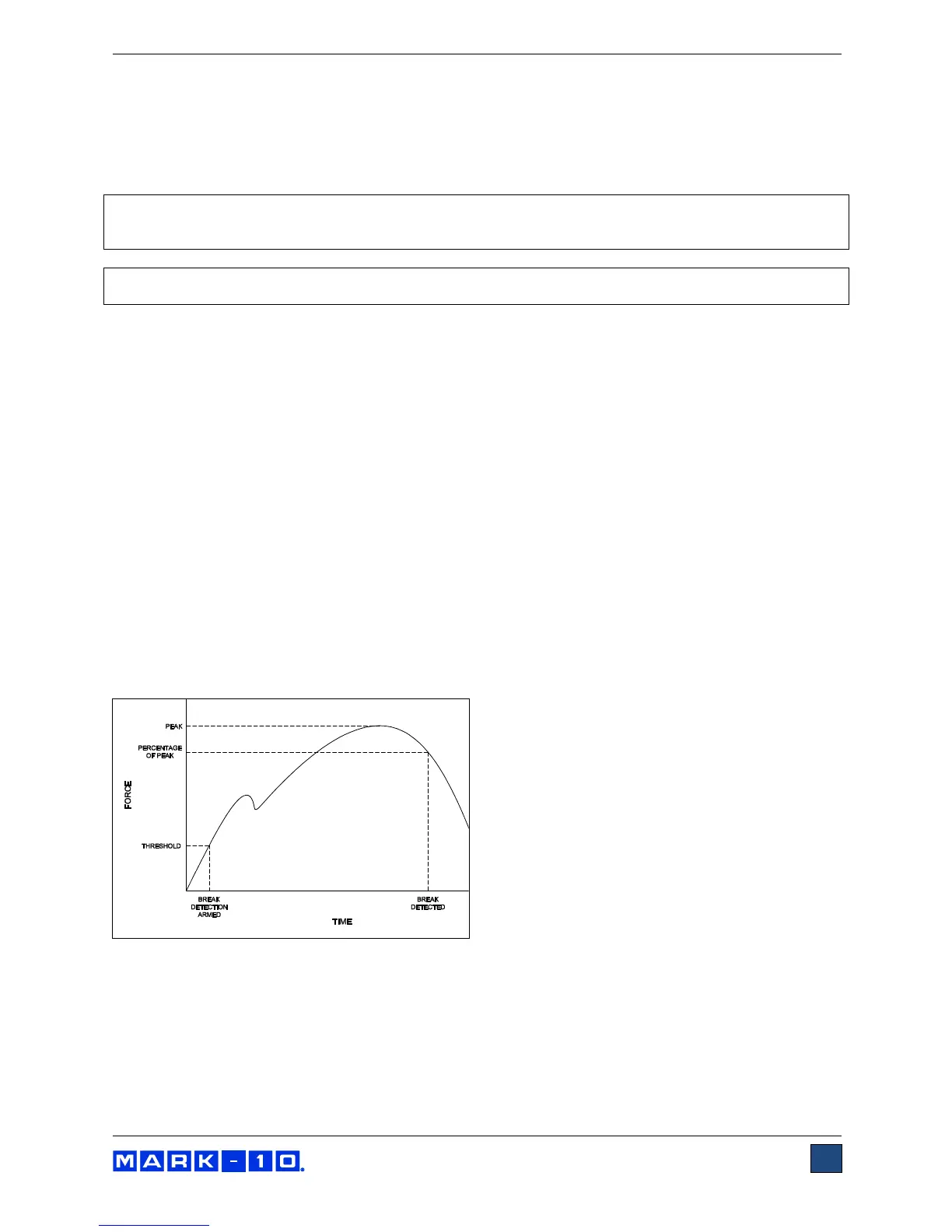

5.9 Break detection mode

In this mode, the crosshead will stop when a sample break has occurred. This action occurs when the

force decreases to a specified percentage of peak, as illustrated below:

If enabled, an auto-return sequence or single-cycle sequence may follow break detection.

Loading...

Loading...