11 MAINTENANCE AND SERVICE

The ESM303 should be operated in a dry and clean area. Under these circumstances only a few periodic

maintenance operations are required:

11.1 Ball screw lubrication – at least twice per year

Periodic lubrication improves performance and increases the longevity of test stand components. On

average, lubrication is recommended twice per year. However, the frequency should increase if the stand

is operated in adverse environmental conditions, including airborne dust, temperature and humidity

extremes, and other factors. Frequent test stand usage also necessitates more frequent lubrication.

Follow these instructions for proper ball screw lubrication:

1. Power off the test stand and disconnect all cables.

2. Remove the left sheet metal and electronics support plate as described in previous sections.

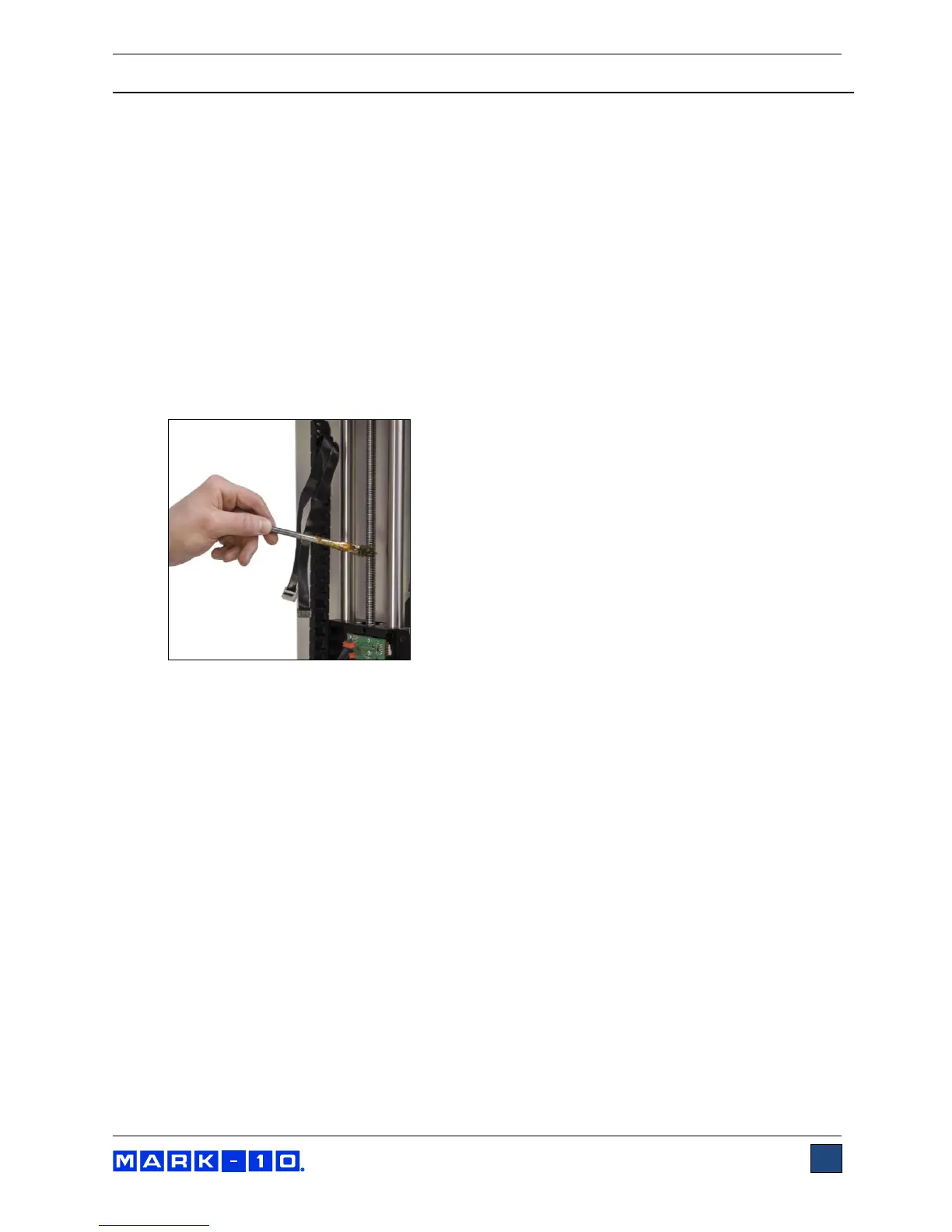

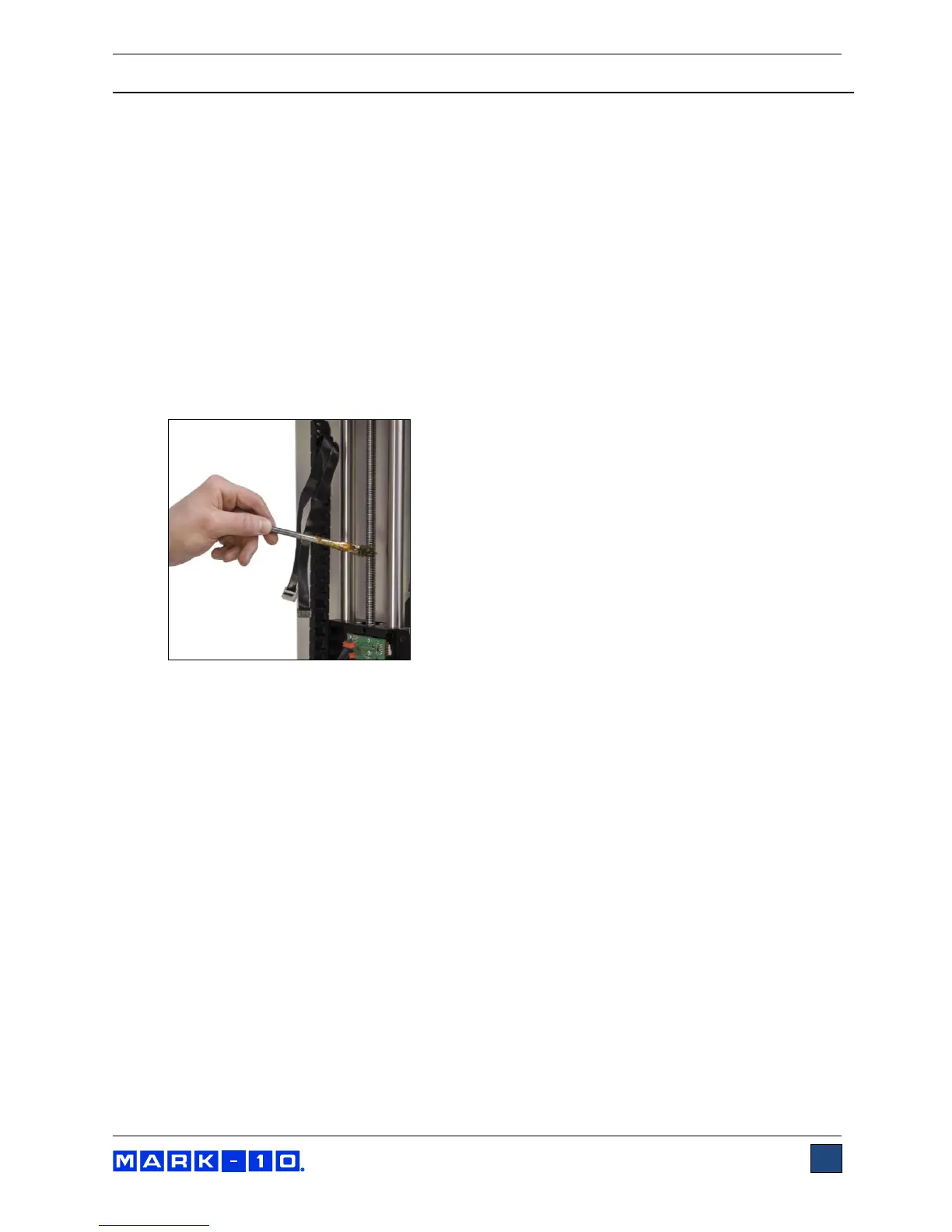

3. Using a brush, apply a small amount of general purpose bearing grease to the screw, as shown

in the image below:

4. Cycle the crosshead several times until the newly applied grease has been spread evenly over

the length of the screw.

5. Re-install the hardware. Be sure to position the upper limit switch above the crosshead and the

lower limit switch below the crosshead before installing to the electronics support plate.

11.2 Check for loosened grips and attachments – daily

Check to ensure that the grips attached to the force gauge and base plate are firmly secured. Looseness

could result in a potentially hazardous situation.

11.3 Check for loosened components – once per month

1. Remove the test sample from the test stand.

2. Attempt to loosen subcomponents of the test stand (ex. fasteners, brackets, etc). All components

should be firmly attached. If any looseness is detected, stop using the test stand and contact

Mark-10 or a distributor for instructions.

11.4 Removing and replacing the Electronics Support Plate

As described earlier, most electronics are mounted to a support plate located along the left side of the

column. It is designed for quick removal and replacement in the event of service or repair. If instructed by

Mark-10 or a distributor to remove and/or replace this plate, follow the instructions outlined in the

Installing the Travel Indication Option section.

Loading...

Loading...