CSP-HMI-3MD Helicopters, Inc.

MAINTENANCE MANUAL

[ Main Menu ]

[ HMI−3 Book TOC ]

[ Chapter 96 TOC ]

96-00-00

Page 601

Revision 13

The information disclosed herein is proprietary to MD Helicopters, Inc.

Neither this document nor any part hereof may be reproduced or transferred to

other documents or used or disclosed to others for manufacturing or any other

purpose except as specifically authorized in writing by MD Helicopters, Inc.

Copyright © 1999−2016 by MD Helicopters, Inc.

ELECTRICAL POWER

INSPECTION/CHECK

1. Module Inspection

(Ref. Figure 601)

NOTE: This procedure covers the inspection of

terminal blocks, terminal modules, ground

blocks, and electrical relays.

(1). Visually inspect module grommet

condition using following criteria:

(a). Module insert grommets shall be free

from cuts, cracks, and splits from

contact cavity to grommet outside

edge, or from cavity to cavity.

(b). Minor scuffs, scrapes, cuts, and

gouges in the grommet that do not

degrade wire sealing or functionality

of module are acceptable.

(2). Replace module if grommet condition is

not acceptable (Ref. Installation and

Removal of Electrical Components)..

(3). Inspect module for contamination by

fluids and dirt particles.

(a). If contamination is found, decontami

nate module (Ref. Cleaning and

Protection Practices).

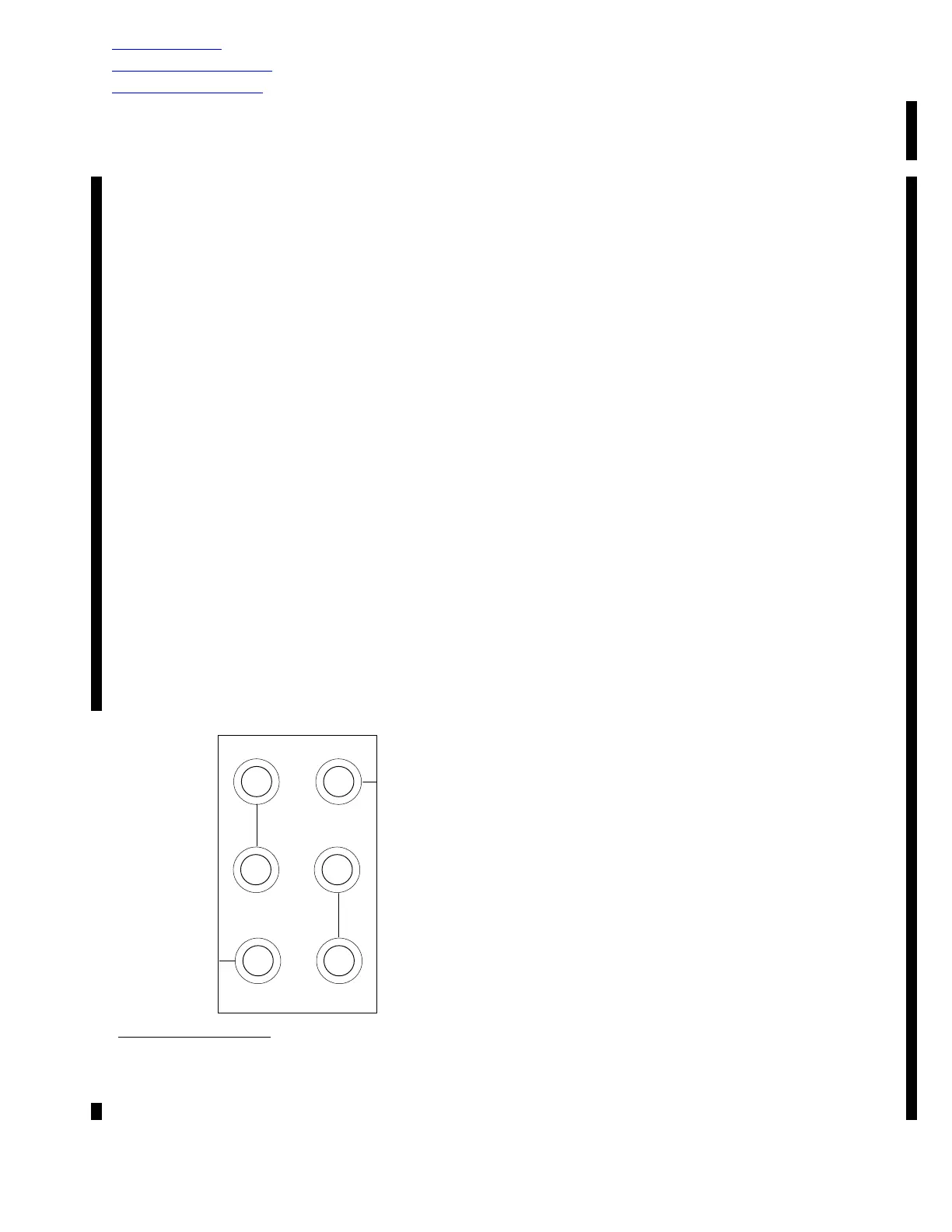

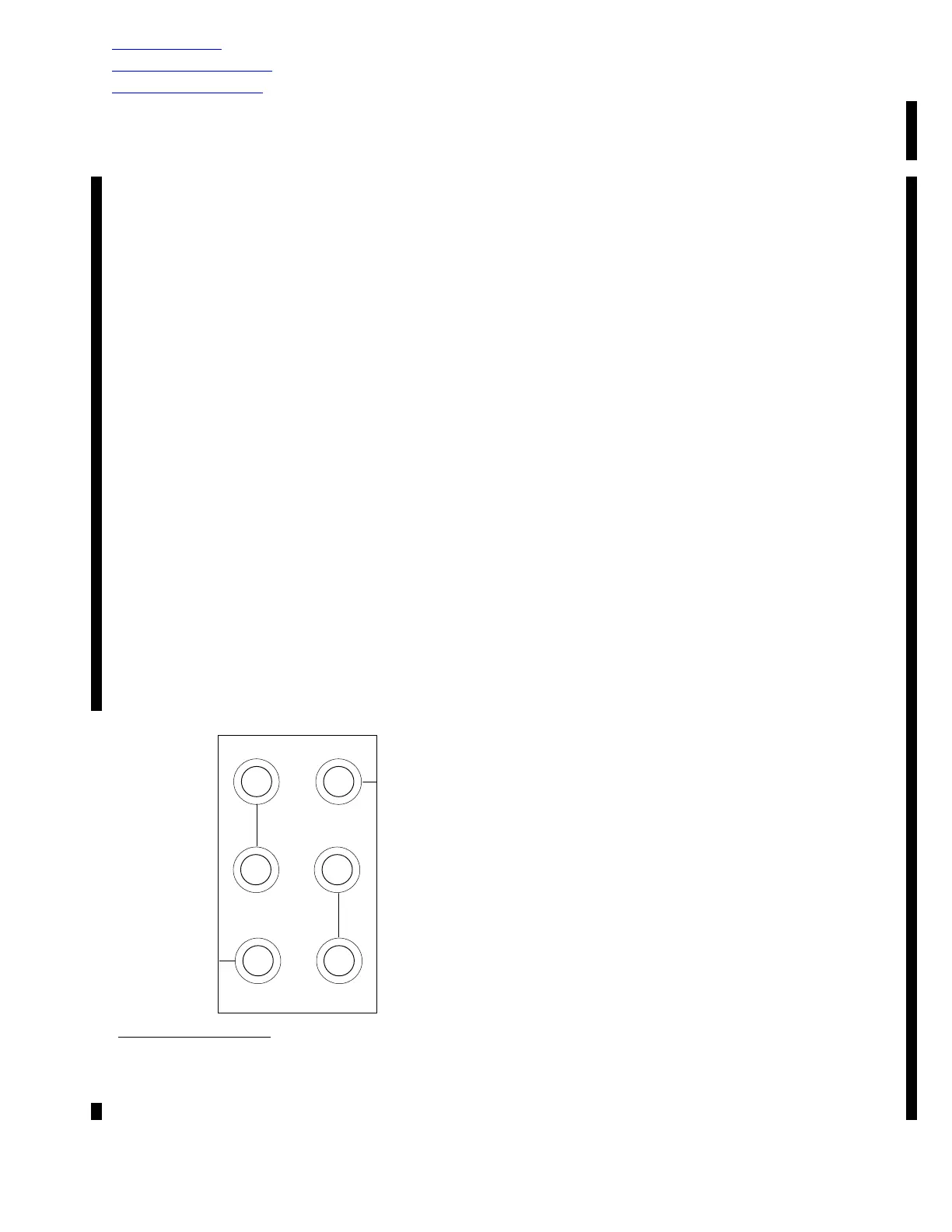

G96-0032

1

2

1

UNACCEPTABLE CONDITIONS:

1. SPLIT OR CUT FROM CONTACT CAVITY

TO GROMMET EDGE.

2. SPLIT OR CUT FROM CONTACT CAVITY

2

Figure 601. Grommet Damage Criteria

2. Connector and Accessories Inspection

(Ref. Figure 602)

NOTE: This procedure covers the inspection of

plugs, receptacles, backshells, and any asso

ciated connector accessory.

(1). Visually inspect connector and accesso

ry condition using following criteria:

(a). Minor scratches and abrasions to

surfaces, keys and keyways, includ

ing exposure of metal under dark

green coatings shall be considered

normal wear and are acceptable.

(b). Surfaces shall be free of scratches,

abrasions, gouges, dents, or other

conditions which deface markings,

create burrs or rough edges in base

material, mutilate keys and key

ways, or interfere with proper

mechanical function.

(c). Connectors with an EMI spring that

has broken or missing fingers/seg

ments shall be rejected. Bent or

displaced fingers are acceptable

provided connector can be fully

mated and unmated to counterpart

without causing further damage.

(2). Replace component if condition is not

acceptable (Ref. Electrical Connector

Maintenance Procedures).

(3). Inspect connector for contamination by

fluids and dirt particles.

(a). If contamination is found, decontami

nate connector (Ref. Cleaning and

Protection Practices).

(4). Visually inspect connector grommet

condition.

(a). Replace connector if grommet condi

tion is not acceptable.

Loading...

Loading...