10 Maintenance

48

10 Maintenance

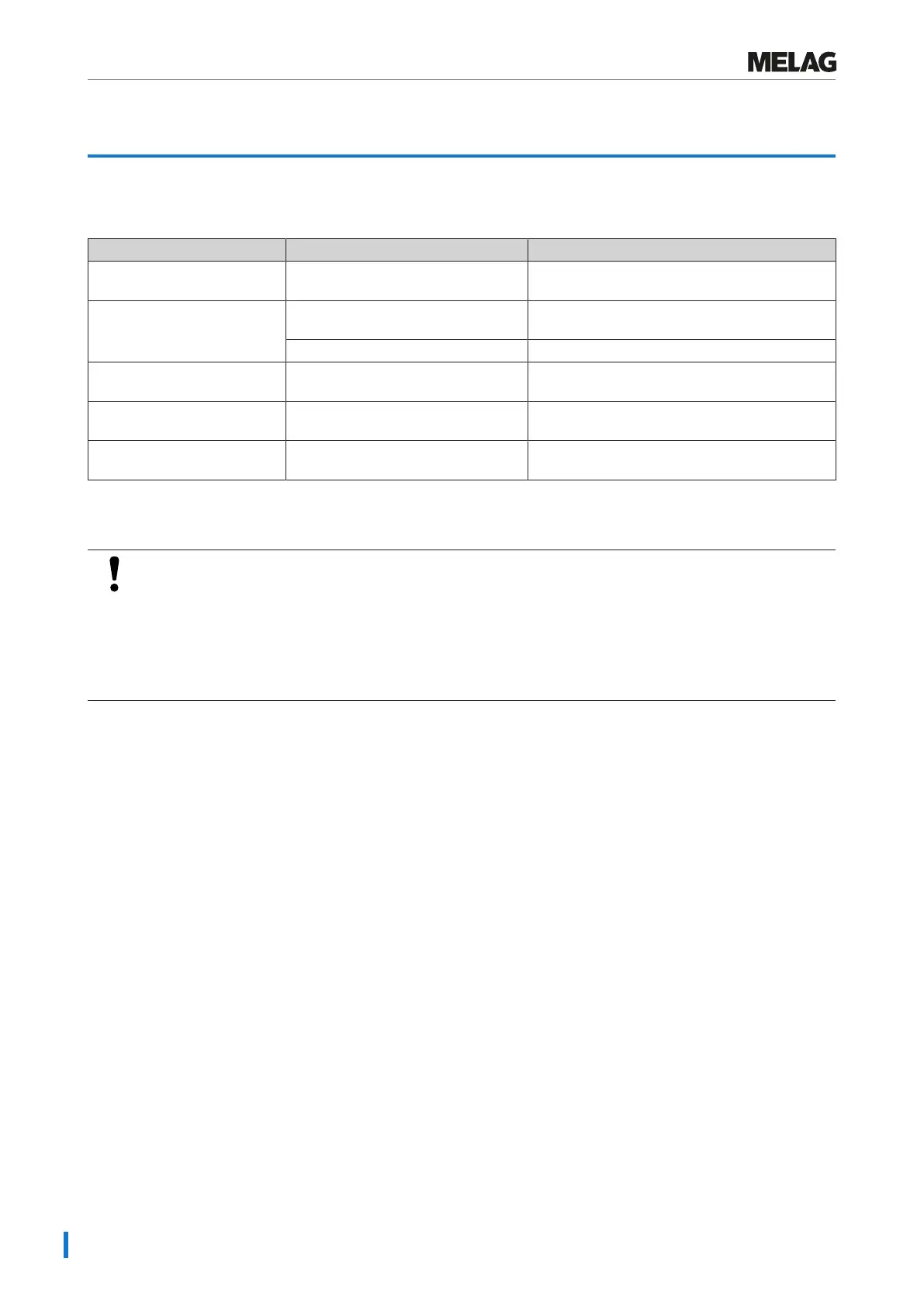

Maintenance intervals

Interval Measure Device component

With every filling of the feed

water container

Check the container for soiling and

clean it if necessary before filling

External feed water container

Weekly Check for soiling, deposits or damage Sterilization chamber including door gasket and

wiping rubber, universal basket for load

Check for discolouration Sterile filter (MELAquick 12+)

Every 4 weeks Check for soiling Insulating plug on the sterile filter

(MELAquick12+p)

As required Cleaning the surfaces Housing parts, sieve tray of the sterilization

chamber, external wastewater container

After 24 months or 3000

cycles

Maintenance by the authorised customer services working in

accordance with the maintenance instructions

Cleaning

NOTICE

Inappropriately performed cleaning can lead to the scratching of and damage to surfaces and the

development of leaks in sealing surfaces.

This also favours the development of soiling deposits and }corrosion in the }sterilization chamber.

n Comply with all information regarding cleaning of the part affected.

n Do not use any hard objects for cleaning such as a metal saucepan cleaner or a steel brush.

Door gasket and sterilization chamber

To maintain the value of your device and to avoid persistent soiling and deposits, MELAG recommends weekly cleaning

of the surfaces such as the sterilization chamber including the door gasket and wiping rubber (e.g. with the MELAG

chamber cleaning set).

The following must be fulfilled or present:

ü

The device has been switched off and the power plug has been unplugged from the socket.

ü

The device has been completely cooled.

ü

The sterilization chamber is empty.

1. Wet the surfaces to be cleaned completely with the cleaning fluid. PLEASE NOTE: You should not allow cleaning

fluid to enter the piping coming from the sterilization chamber.

2. Spread the cleaning fluid evenly with a non-fuzzing cloth.

3. Allow the cleaning fluid to act and evaporate for a sufficient time.

4. Using a new non-fuzzing cloth, spread ample amounts of demineralised water over the cleaned surfaces.

5. Wipe the surfaces thoroughly to remove cleaning residues. Repeat this process as necessary after wringing out the

cloth.

Ê Residues of cleaning fluids can ignite or cause deposits on the instruments.

6. Allow the cleaned areas to dry completely. This may take a few minutes.

7. Finally, wipe the cleaned surfaces with a dry, non-fuzzing microfibre cloth.

8. Clean the wiping rubber and the door seal using a commercially available, gentle liquid cleaning agent.

Loading...

Loading...