3 Performance specifications

9

Safety equipment

Internal process monitoring

A }process evaluation system is integrated in the electronics of the steam sterilizer. It compares the process parameters

(such as temperature, time and pressure) during a program run. It monitors the parameters in terms of their threshold

values during control and regulation and guarantees safe and successful sterilization. A monitoring system checks the

device components of the steam sterilizer for their functionality and interplay. If one or more parameters exceeds pre-

determined threshold values, the steam sterilizer issues warning or malfunction messages and if necessary, aborts the

program. In the case of a program abort, follow the instructions on the display.

The steam sterilizer uses an electronic parameter control. This enables the steam sterilizer to optimise the total operating

time of a program in dependence on the load.

Door mechanism

The steam sterilizer constantly checks pressure and temperature in the sterilization chamber and prevents the door from

being opened when over-pressure has built up.

Quantity and quality of the feed water

The quantity and quality of the }feed water is automatically checked before every program start.

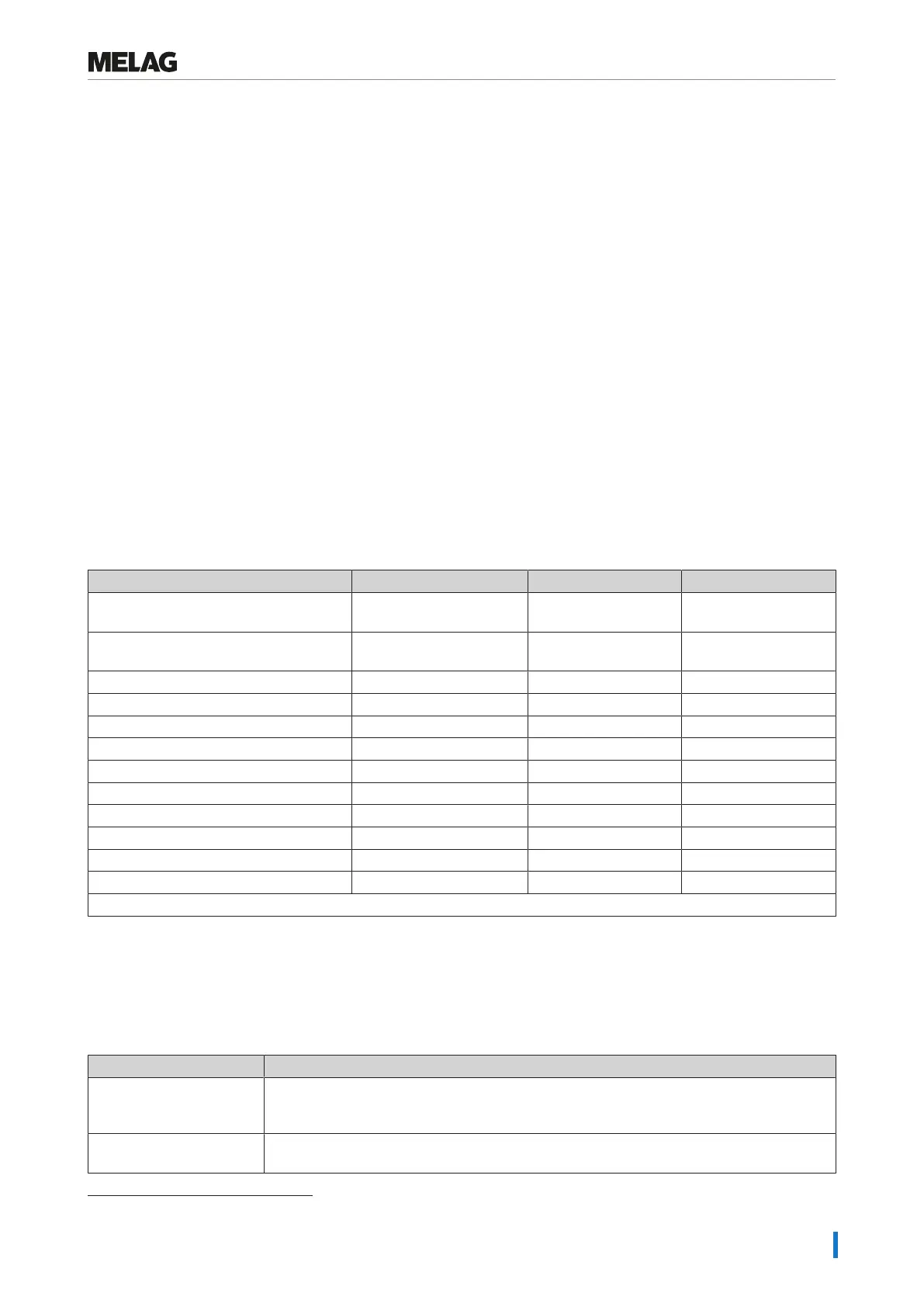

Performance characteristics of sterilization programs

The results in this table show which inspections were performed on the steam sterilizer. The marked fields demonstrate

compliance with all the applicable sections of the standard }EN 13060.

Type tests Universal-Program S Quick-Program S Prion-Program S

Program type in accordance with

EN13060

Type S Type S Type S

Dynamic pressure test of the sterilization

chamber

X X X

Empty chamber test X X X

Solid load X X X

Simple hollow bodies X X X

Dental transmission instruments

2)

X X X

Single wrapped X -- X

Drying solid load X X X

Sterilization temperature 134 °C 134 °C 134 °C

Sterilization temperature range + 4 °C + 4 °C + 4 °C

Sterilization pressure 2.1 bar 2.1 bar 2.1 bar

Sterilization time 05:30 min 03:30 min 20:30 min

X = Complies with all applicable sections of the standard EN 13060

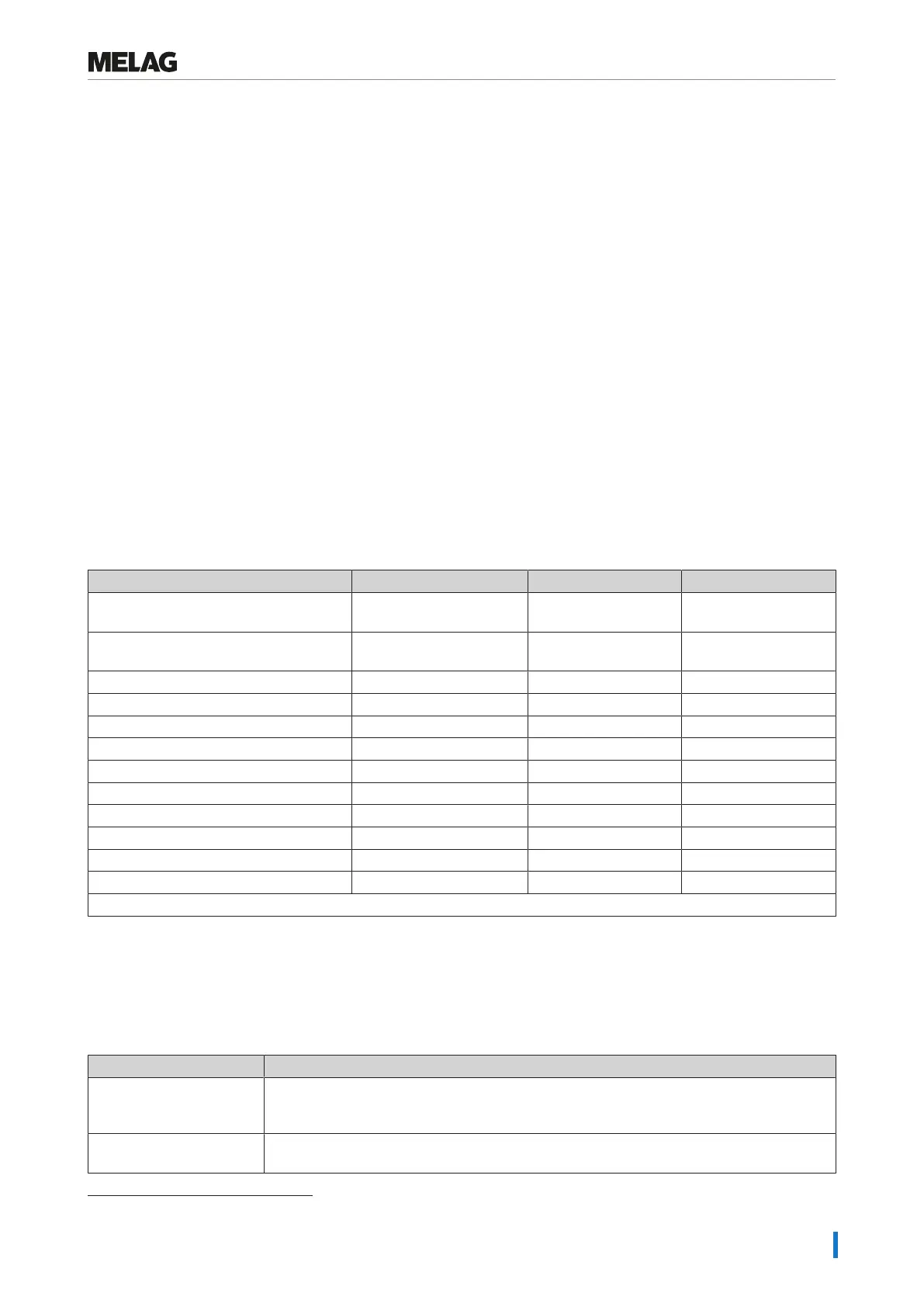

Program sequences

Regular sterilization program

After program start, you can follow the program run on the display. It shows the chamber temperature and pressure as

well as the time until the end of sterilization and drying.

Program phase Description

1. Air removal phase The fractionated flow procedure removes the air from the sterilization chamber through

pulsing repeated steam injection and removal. Depending on the program selected and the

current chamber temperature upon program start, further fractionation can also follow.

2. Heating phase The heating phase follows the air removal phase. The pressure and temperature increase

until the program-specific sterilization parameters have been reached.

2)

Further information is provided in the certificate of suitability (enclosed).

Loading...

Loading...