10 Maintenance

50

Avoiding staining

Only proper cleaning of the instruments prior to sterilization enables you to avoid residue from being released from the

load under steam pressure during sterilization. Loosened dirt residue can clog the filter, fittings and valves of the device

and deposit themselves on the instruments and in the sterilization chamber as deposits and stains.

All steam-conducting parts of the device consist of non-rusting material. This rules out the possibility of stain or rust

development being caused by the steam sterilizer. Any rust which develops is always extraneous rust.

Incorrect instrument reprocessing can result in the accretion of rust even on stainless steel instruments of leading manu-

facturers. Often, a single instrument which drops rust can suffice to cause the development of rust on other instruments

or in the device. Remove foreign rust from the instruments using chlorine-free stainless steel cleaning fluid (see Cleaning

[}page48]) or send the damaged instruments to the manufacturer.

The extent of stain accretion on the instruments is also dependant on the }feed water used for steam generation.

Replacing the door gasket

Replace the door gasket in good time if it shrinks, becomes very wavy or has cracks in the sealing lip. The consequence

can be leaks which can lead to the leakage of steam. Safe and successful sterilization may be impacted.

1. Remove the worn door gasket from the groove.

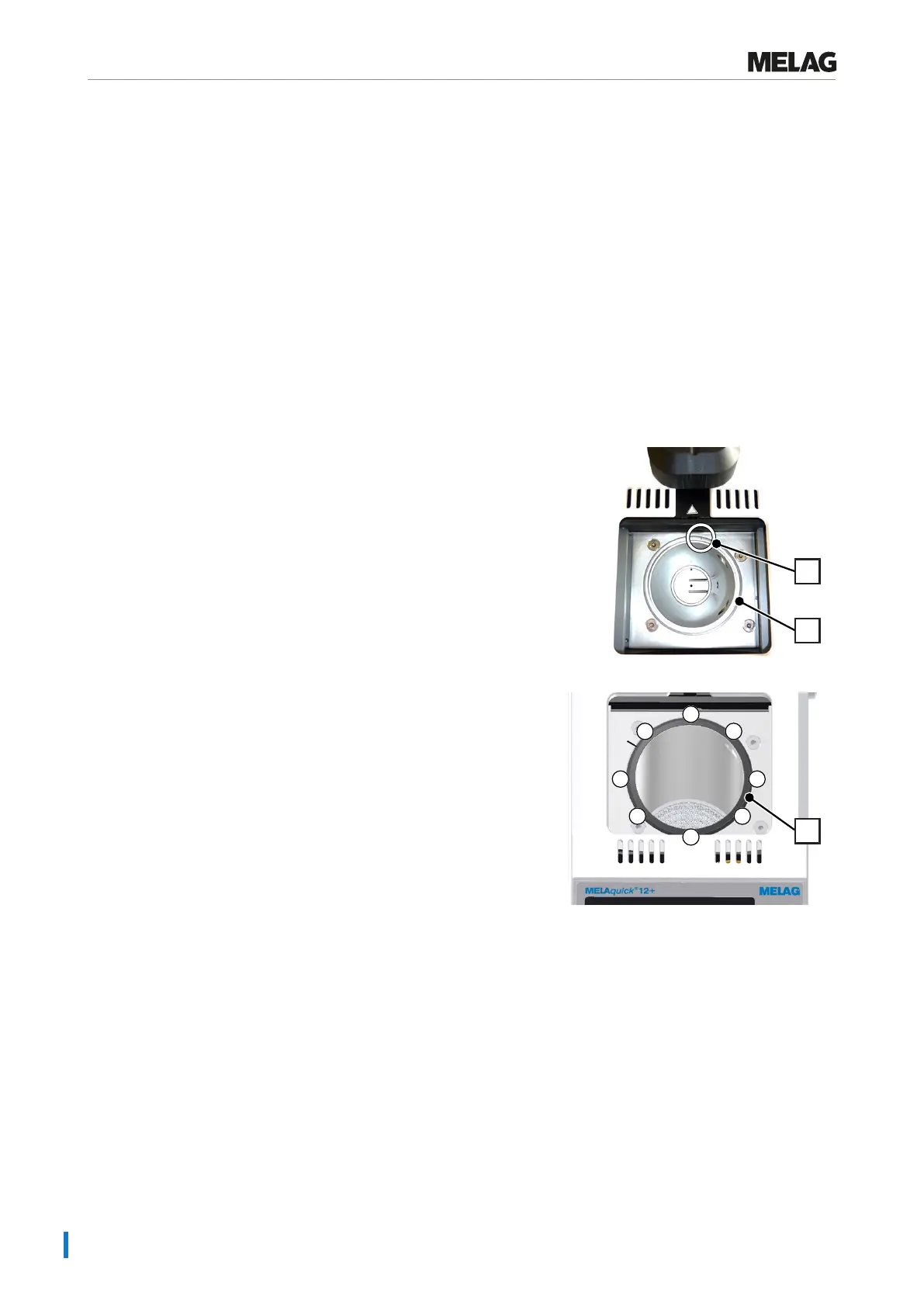

2. Check the groove (pos. b) for soiling and deposits.

3. If necessary, clean the groove with methylated spirit.

A ventilation hole (pos. a) is located in the base of the groove

(pos. b) in the chamber opening on the opposite side to the

operating panel through which the air underneath the gasket can

escape.

4. Spread a little washing-up liquid solution (1 part commercial

dishwashing detergent + 4 parts water) on the new door gasket

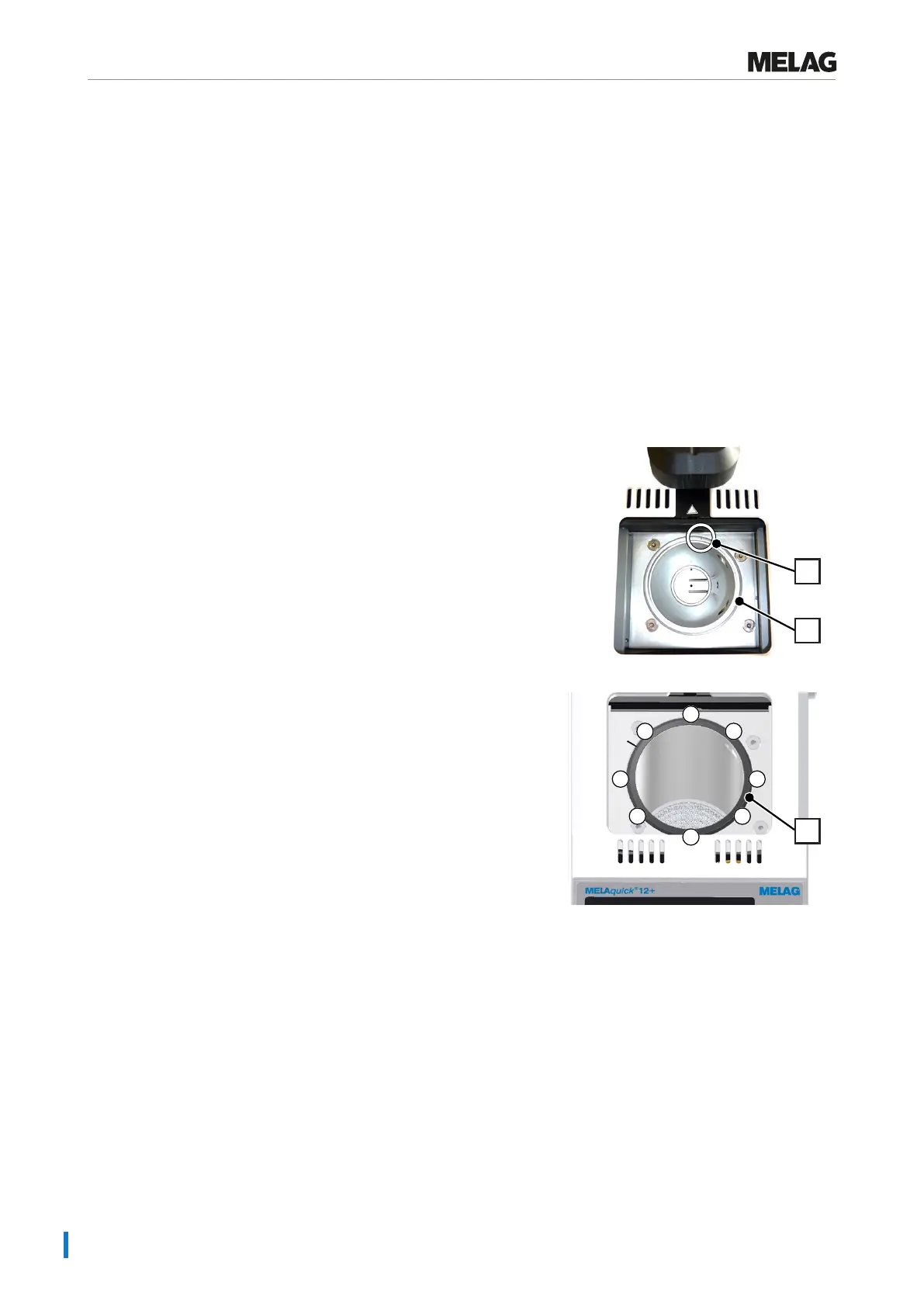

(pos. c) to make it easier to insert. NOTICE!Do not move the

door gasket in the groove.

5. Place the door gasket loosely on the groove and press it into the

groove at a point about 45° (position 1) offset from the ventilation

hole.

6. First press the door gasket into the groove on the opposite side

and then press it crosswise at points.

7. Press down the locations between these points already inserted

into the groove in a cross-wise fashion etc.

8. Finally, starting from position 5 on the left, press the door gasket

into the groove in short intervals working clockwise in the

direction of the ventilation hole.

9. Perform a trial run and then check the stability and position of the

door gasket. If necessary, press down any bulges with a blunt

instrument up to position 8 and then press the gasket into the

groove in this position as well.

Loading...

Loading...