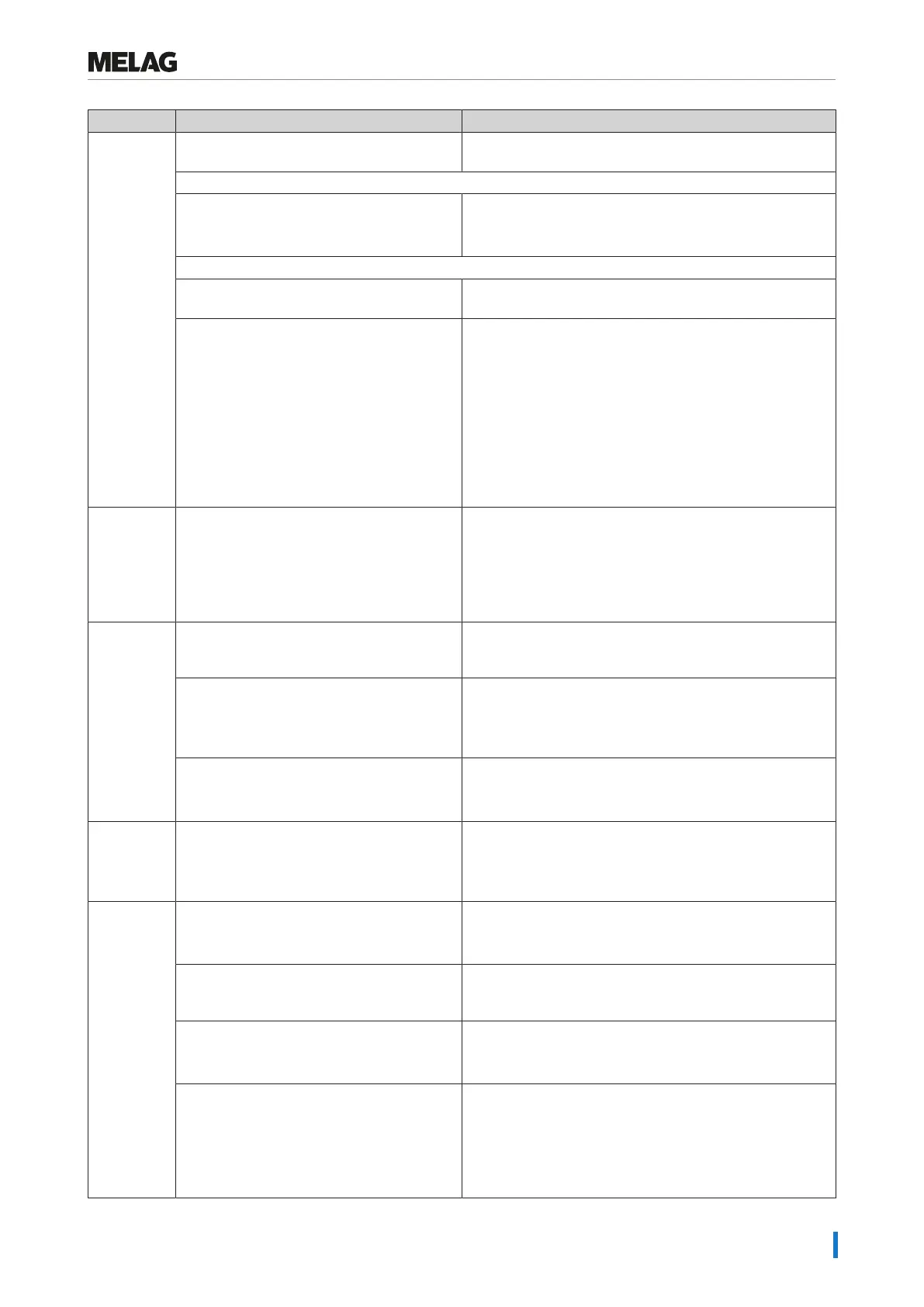

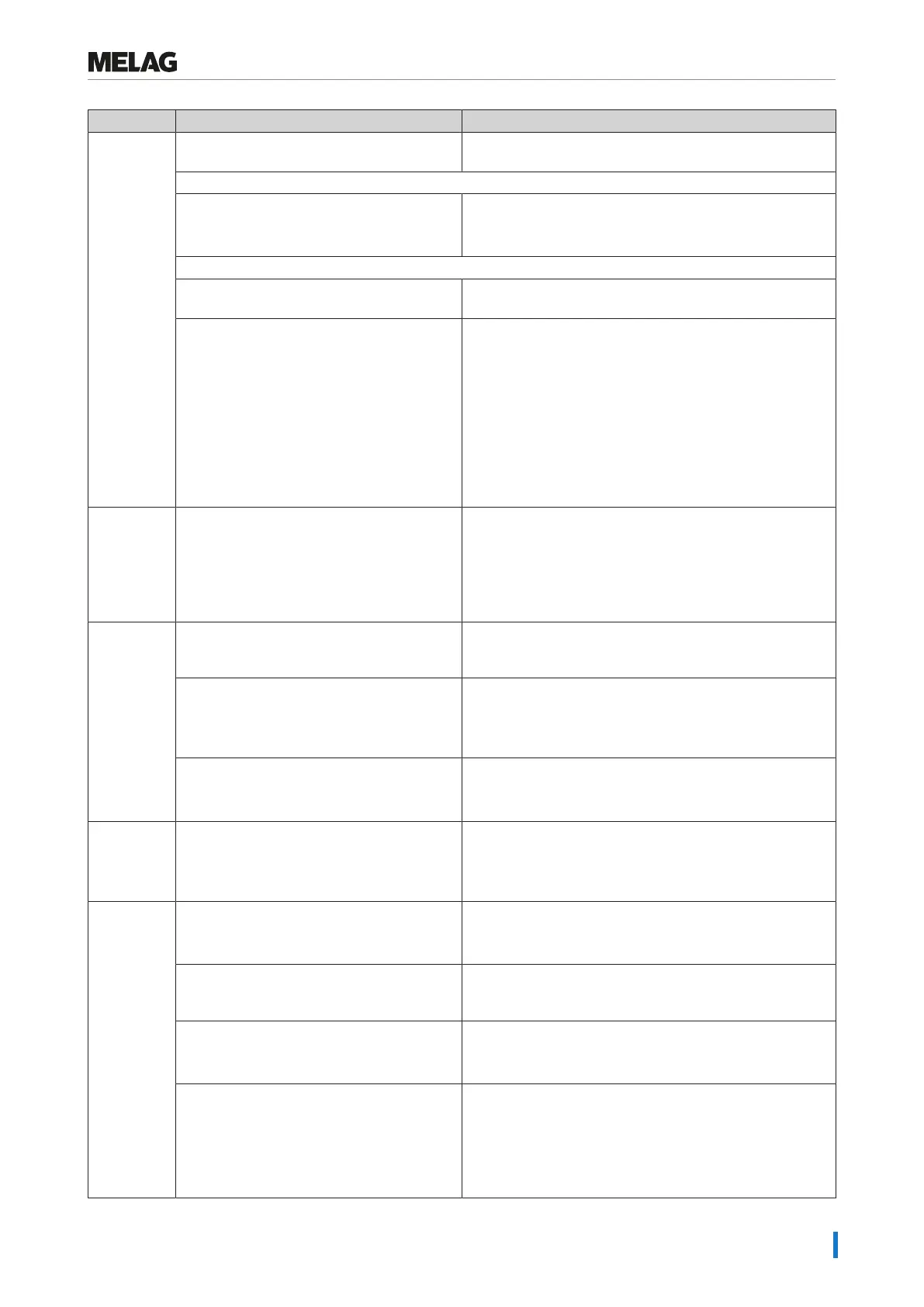

12 System malfunctions

61

Event Possible causes What you can do

F25 The quality of the feed water is very poor

(conductivity ≥65μS/cm).

--

When using the feed water container:

Water of insufficient quality (e.g. tap water)

was used.

1. Empty and clean the container.

2. Fill the container with water of appropriate quality

(EN13060, Appendix C).

When using a MELAG water treatment unit:

MELAdem40:

The mixed-bed resin cartridge is exhausted.

Replace the mixed-bed resin (art. no.ME61026), see the

user manual of the MELAdem40 water treatment unit.

MELAdem47:

The mixed-bed resin cartridge, the pre-filter

or the activated coal filter is exhausted.

1. Replace the mixed-bed resin (art. no.ME37470) and, if

necessary, the pre-filter and activated charcoal filter,

see the user manual of the MELAdem47 water treat-

ment unit.

2. Empty the pressure tank (if possible until it is half full)

and wait until it has been filled again. An empty pres-

sure tank requires approx. 1 h to fill.

PLEASE NOTE: The message may also continue to be

shown after the filter has been replaced until the water

remaining in the pressure tank has been consumed.

F26

F27

Electromagnetic malfunctions in the power

supply.

1. Check the building-side socket / test the steam

sterilizer using a different socket or circuit or connect

to a mains filter.

2. Upon repeated incidence, arrange for an electrician to

check the electricity supply for electromagnetic mal-

functions.

F32 The steam sterilizer was switched off at the

power switch during a program run.

Never switch off the steam sterilizer at the power switch

during a program run. Always abort a program with the

'Start-Stop' key.

The power plug has been disconnected or

has not been connected correctly in the

socket.

1. Check whether the power plug is connected, the power

cable has suffered damage, or a loose contact or loose

plug connections is the cause.

2. Plug the power plug back into the mains socket.

Power failure in the building supply. 1. Have the on-site installation checked (e.g. circuit

breakers).

2. Test the steam sterilizer on another socket or circuit.

F33 The pressure in the sterilization chamber

drops too far during the sterilization phase.

The door does not close tightly, possibly

because the door gasket is soiled or worn.

1. Check whether the door gasket is soiled or worn.

2. Clean or, if necessary, replace the door gasket, see

Replacing the door gasket [}page50].

F34 The sterilization temperature on temperature

sensor 1 was undercut.

The steam sterilizer is overloaded.

Comply with the maximum permissible load quantities, see

Selecting the program [}page33].

The sieve tray in the sterilization chamber is

soiled.

Remove the sieve tray from the sterilization chamber,

clean and replace it, see Sieve tray of the sterilization

chamber [}page49].

The door does not close tightly, possibly

because the door gasket is soiled or worn.

1. Check whether the door gasket is soiled or worn.

2. Clean or, if necessary, replace the door gasket, see

Replacing the door gasket [}page50].

Electromagnetic malfunctions in the power

supply.

1. Check the building-side socket / test the steam

sterilizer using a different socket or circuit or connect

to a mains filter.

2. Upon repeated incidence, arrange for an electrician to

check the electricity supply for electromagnetic mal-

functions.

Loading...

Loading...