1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

6

10

22

25

95

110

95

25

Liquid Neoprene (92-25711--2)

95

2-4-C w/Teflon (92-850736A1)

110

4-Stroke Outboard Oil (92-828000A12)

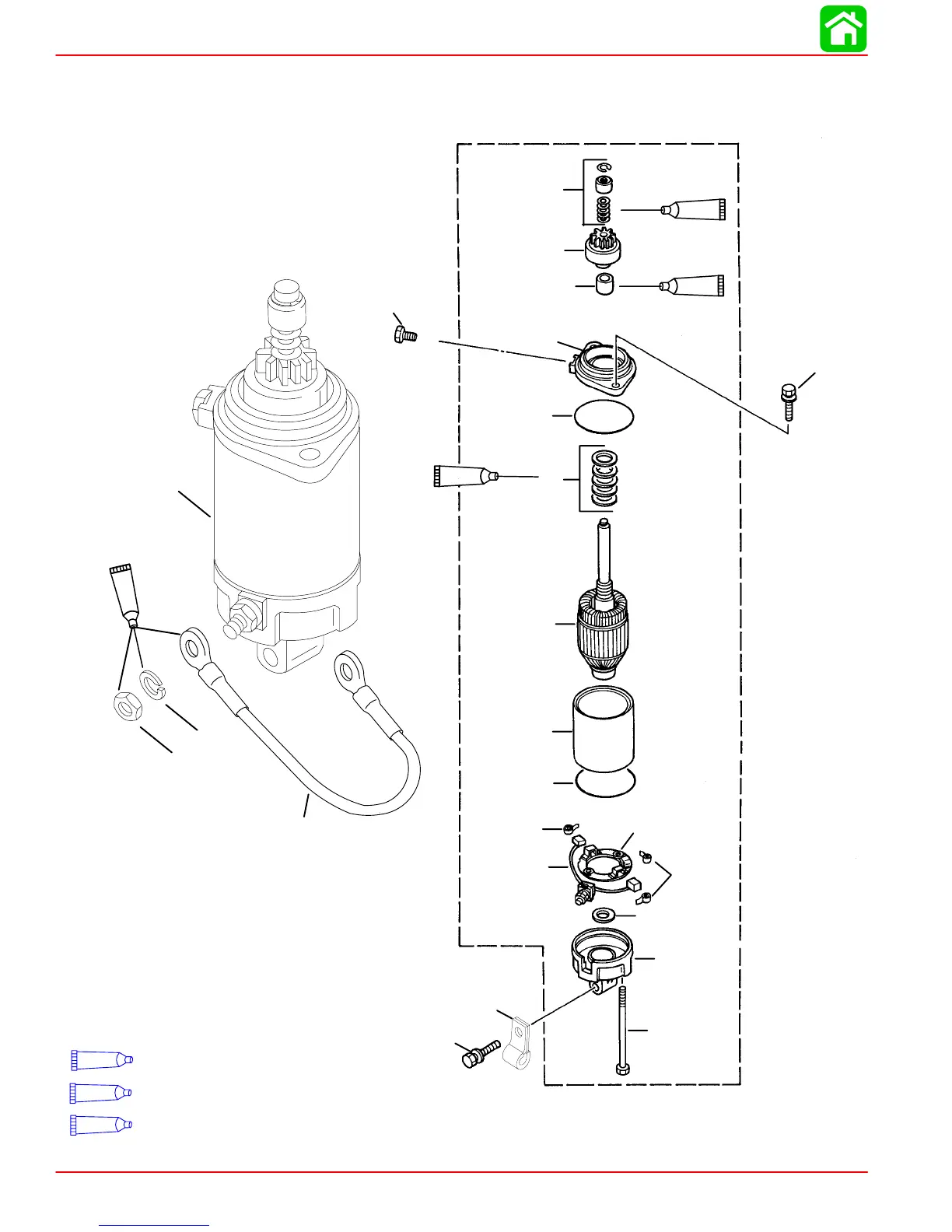

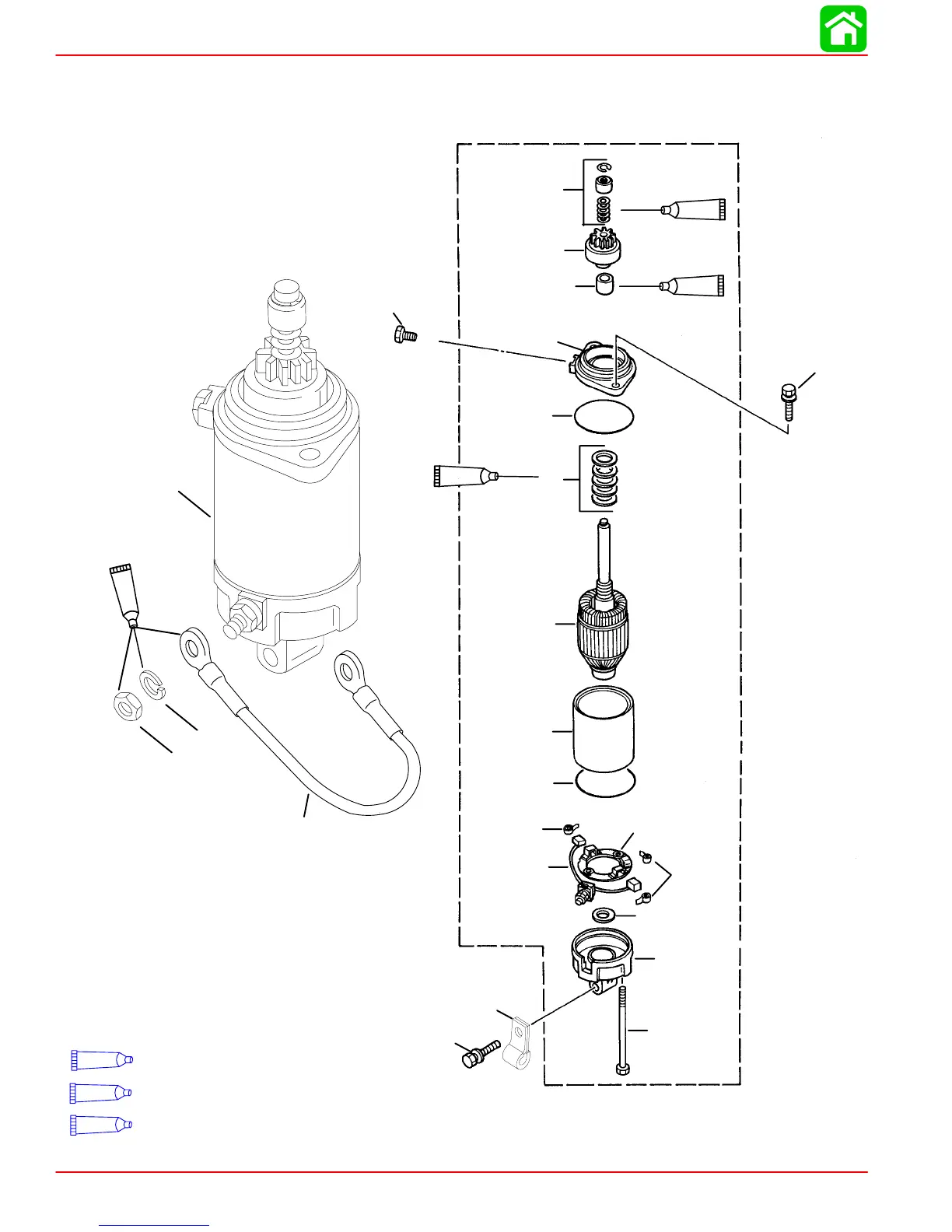

CHARGING AND STARTING SYSTEM

Page 2B-4 90-828631R3 MARCH 1999

Starter Motor (S/N-0G472132 & Below)

Loading...

Loading...