Pneumatic Circuit System Problems Repair and Troubleshooting

5 - 32 046-001141-00 A5/A3™ Service Manual

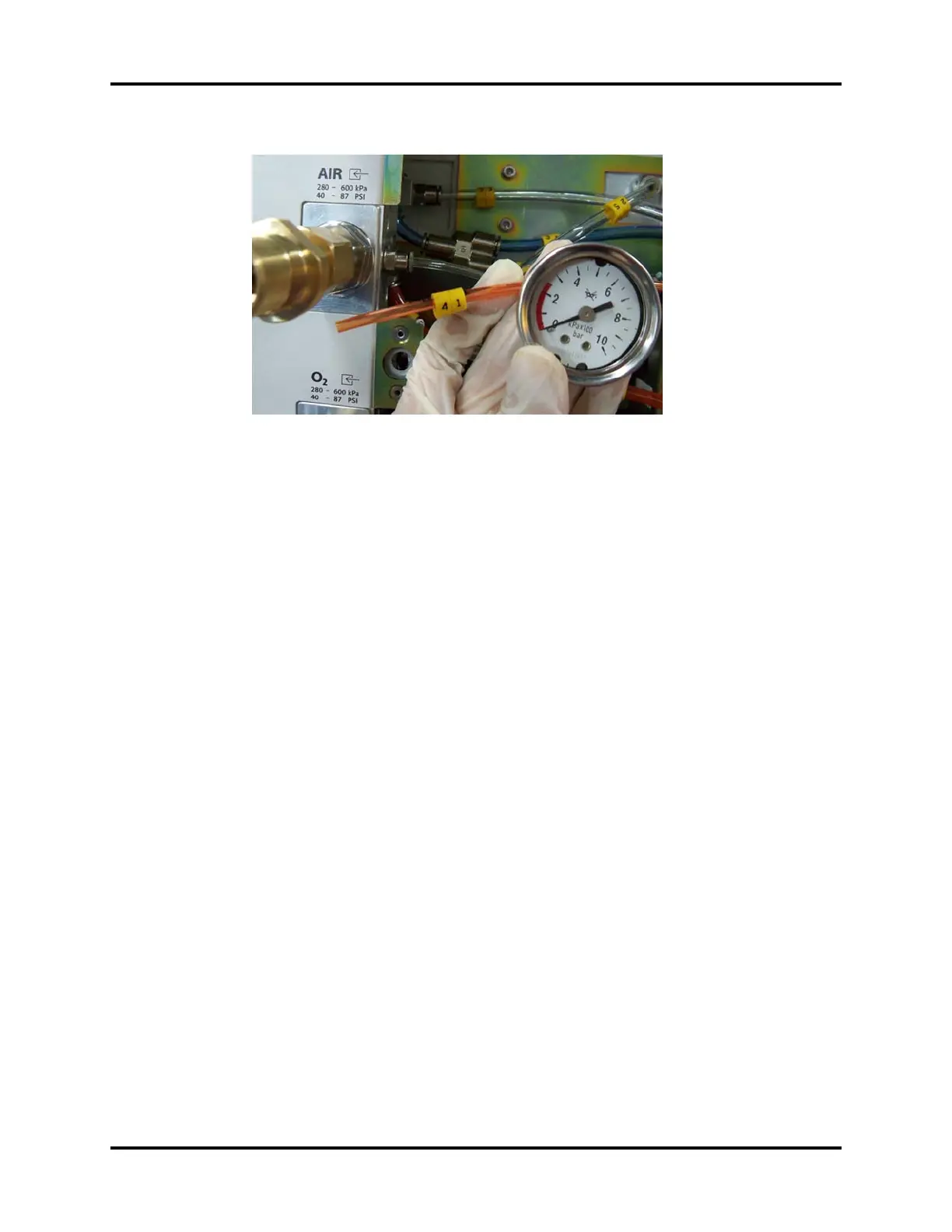

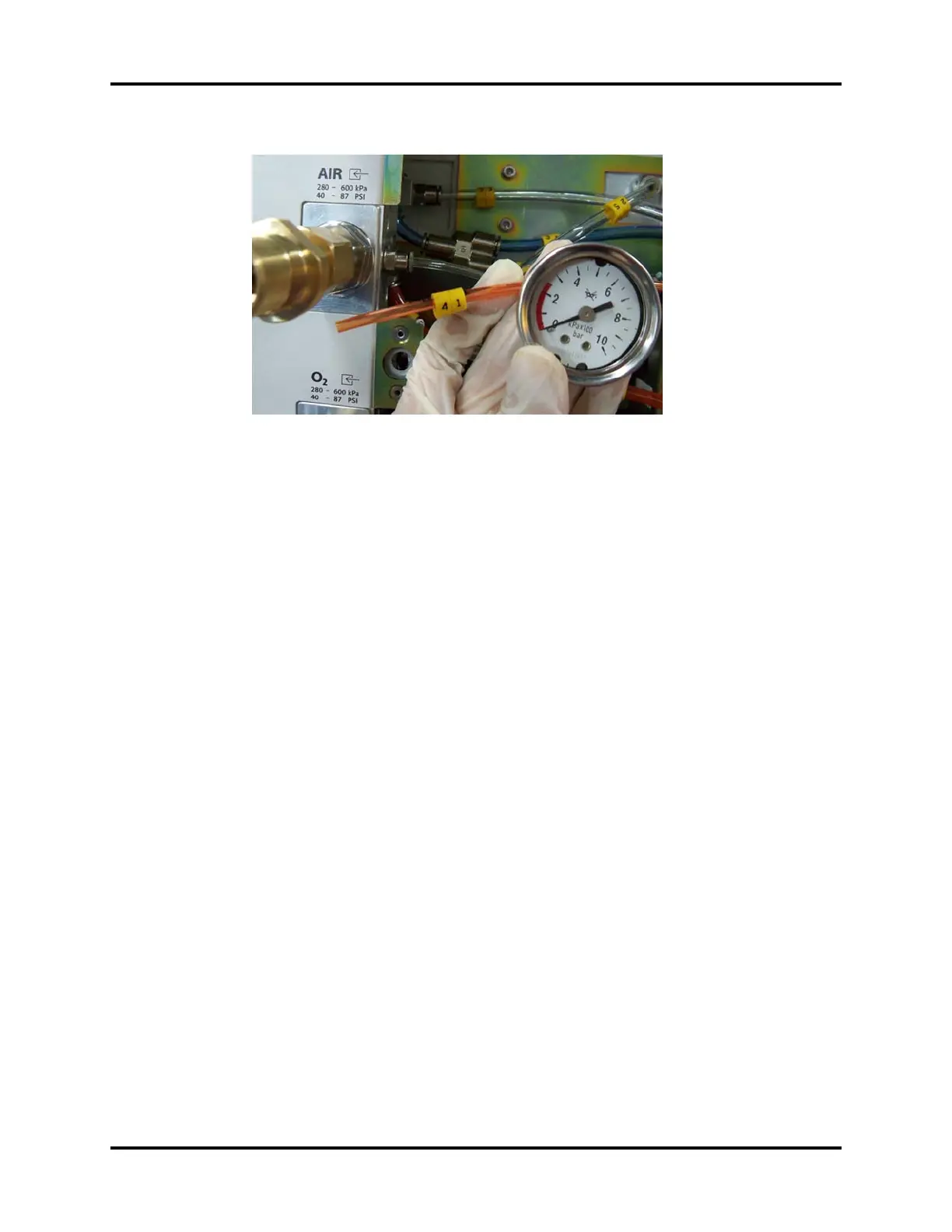

FIGURE 5-26

8. Turn on the AIR pipeline supply and record the reading on the test pressure gauge. If the

difference between this reading and the reading on the AIR pipeline pressure gauge is more

than 0.1 MPa (1.0 bar), it indicates that the AIR pipeline pressure gauge is damaged. Handle this

problem as described in the troubleshooting table.

9. Reconnect PU tube No.41 to the pressure gauge.

5.3.2.2 Test the Pressure Switch

Use the following tools to verify the pressure switches of the O2 supply inlet assembly and the

expiratory valve assembly are within specifications:

• 1 MPa (1.0 bar) test pressure gauge (quantity:1)

• 3106-04-06 adapter connector (quantity:1)

• 3106-06-08 adapter connector (quantity:1)

• 3140-08-00 Y piece (quantity:1)

• PU tube (8X200) (quantity:2)

• PU tube (6X200) (quantity:1)

• PU tube (4X200) (quantity:1)

Test procedures:

1. Turn off the pipeline gas supply and bleed the residual pressure by pushing the O2 flush button.

2. Disconnect tube 47. The end of the tube which connects pressure regulator assembly is pulled

out but the other end is not pulled out.

3. Connect one PU tube (8X200) to the O2 inlet of pressure regulator assembly and connect the

other end of the PU tube and also the pulled-out end of tube 47 to the two connectors of “3140-

08-00 Y piece” respectively.

4. Connect the test pressure gauge to the third connector of “3140-08-00 Y piece” through “3106-

06-08 adapter connector” and “3106-04-06 adapter connector”.

Loading...

Loading...