MKS 937B Operation Manual

104

1. Finger tighten the guard bolt to compress the spring washer and then back off one turn.

Do not overtighten as this will remove all compliance from the spring washer and possibly

damage the aluminum

3

/8"-40 thread.

2. Verify that the anode

14

is well-centered within the bore of the guard bolt.

3. If it is off center, carefully bend it back into position and continue with the assembly.

12.1.2.4 Preparing the Sensor for Bakeout

The 421/422 sensor, including the LEMO connectors in the bulkhead, will withstand bakeout up to 250°C.

Additionally, the sensor may be operated during bakeout if cables and connectors with appropriate

temperature ratings are used. Cables or connectors rated to temperatures less than the bakeout

temperature need to be disconnected from the sensor for bakeout. In applications requiring repeated

bakeouts, the use of bakable connectors and cables is suggested. To prepare the sensor for bakeout up

to 125°C, remove the high voltage and ion current cables only.

12.1.2.5 Testing a Cold Cathode Sensor

HPS cold cathode sensors contain anode and cathode (collector) electrodes. Test the sensor with an

ohmmeter. There should be no shorts between the electrodes or from the electrodes to the sensor body.

12.2 Maintenance of Series 423 I-MAG

®

Cold Cathode Sensor

12.2.1 Connecting the I-MAG Sensor

Mount the Sensor to a grounded vacuum system.

If the I-MAG Sensor has a CF flange, remove the magnet to allow clearance for bolt installation. When

replacing the magnet, note that it is keyed to the sensor body to protect the feedthrough pins from

damage. The pins should be straight and centered.

For grounding, use a conductive, all-metal clamp to mount a KF 25 or KF 40 flanged sensor body.

Connect the cable to the sensor and to the 937B Controller before turning on your system. Tighten the

thumbscrew on top of the cable to make sure it is securely in place.

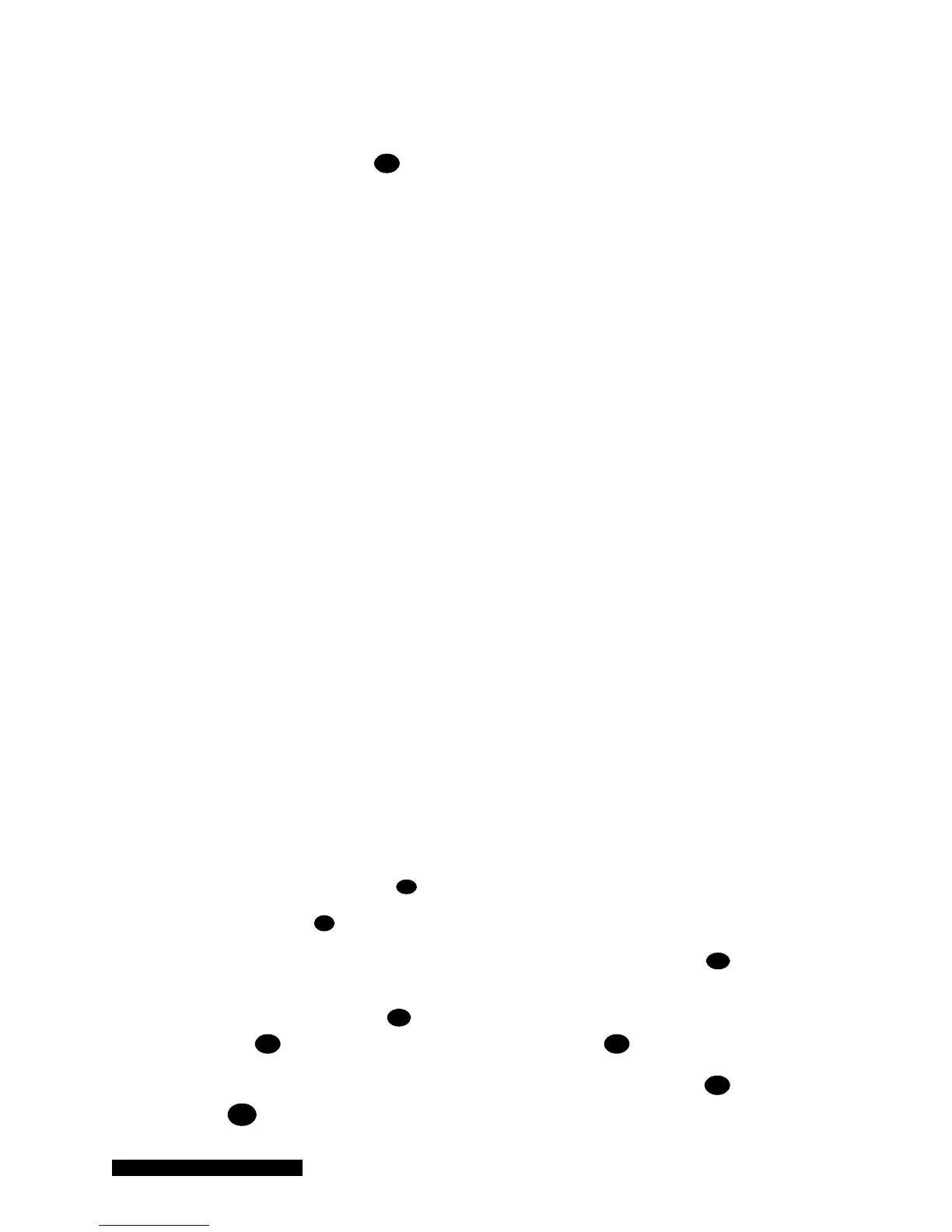

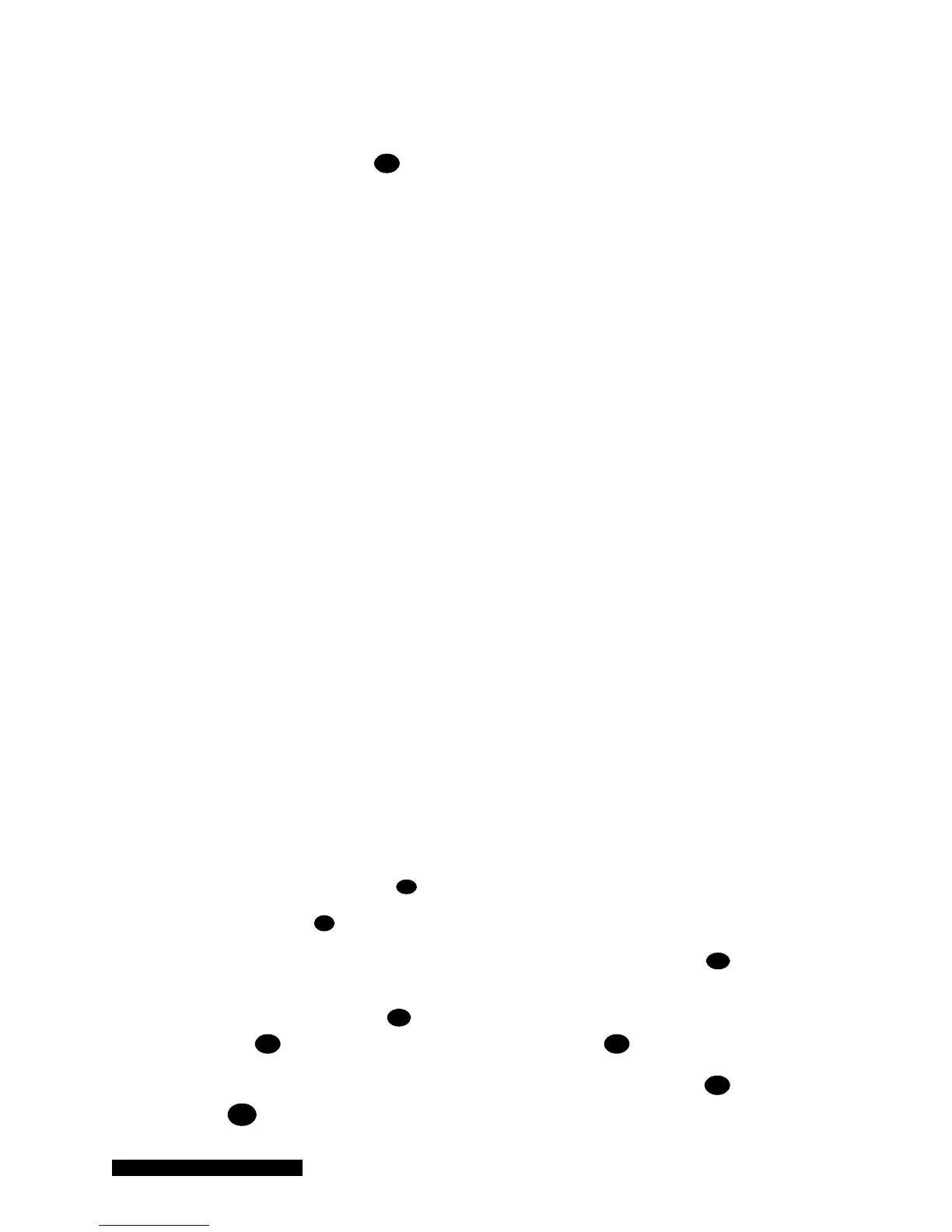

12.2.2 Disassembling the I-MAG Sensor

1. Clean tweezers and clean smooth-jaw, needle-nose pliers are required.

2. Turn off the power to the 937B controller.

3. Loosen the thumbscrew on top of the sensor cable and remove the cable.

4. Loosen the two flat head screws

15

.

5. Remove the magnet

14

.

6. Using the smooth-jaw, needle-nose pliers, firmly grab the compression spring

3

at the

tip closest to the flange.

7. Pull on the compression spring

3

while rotating to free it from the formed groove of the

sensor body

9

. Continue to pull until the compression spring

3

is completely free.

8. With the vacuum port facing up, carefully remove the remaining components (

4

through

8

) from the sensor body.

Loading...

Loading...