OPERATING AND MAINTENANCE MANUAL

Chapter 7 - Electronic controller

TAEevo Tech 015÷802 60 Hz UL

83

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

EN

ENGLISH

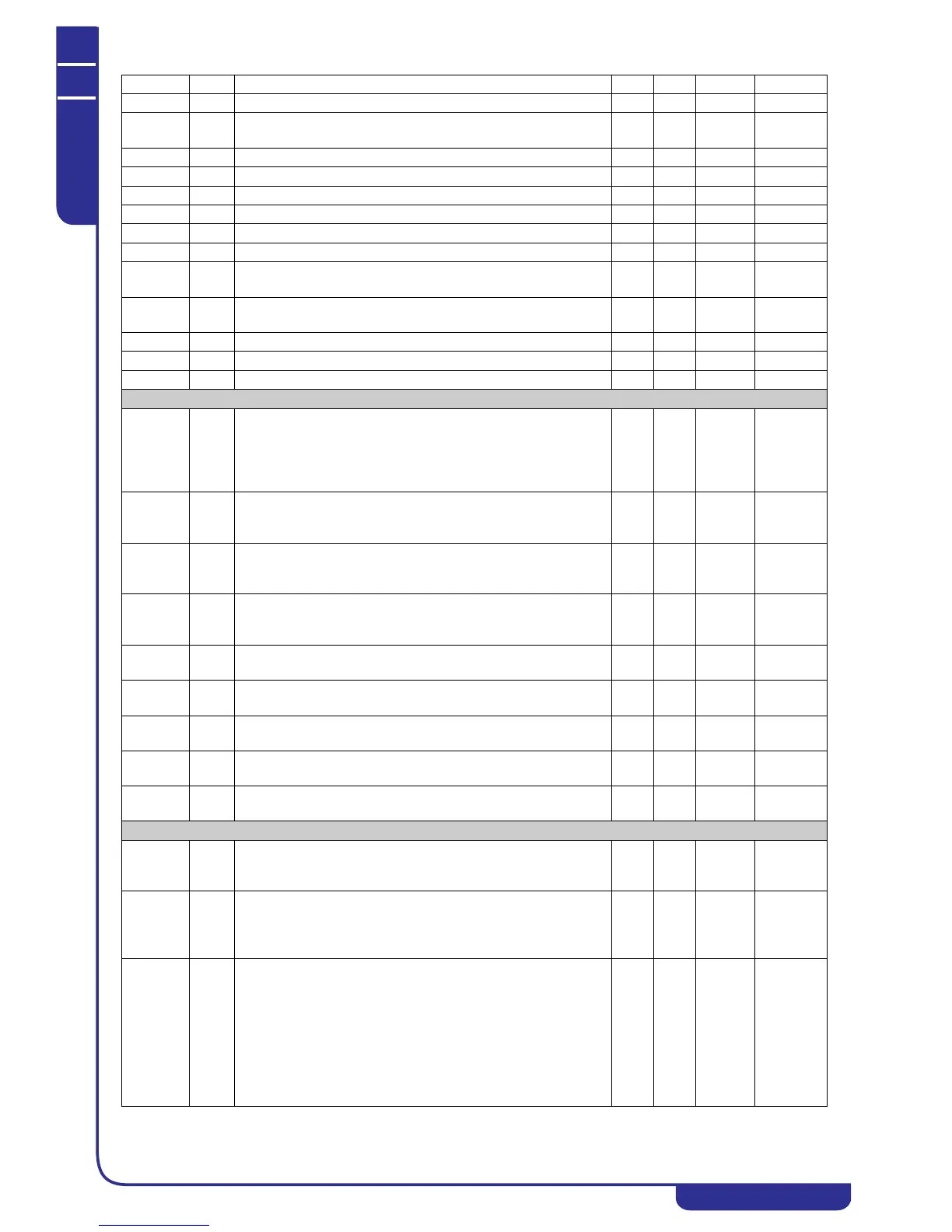

ES24 C End of time band 3 - domestic hot water (0...24) 0 24.00 by Hours 10 Min

ES25 C Monday: energy saving active

Monday operation with domestic hot water time band

07

ES26 C Tuesday operation with domestic hot water time band 0 7

ES27 C Wednesday operation with domestic hot water time band 0 7

ES28 C Thursday operation with domestic hot water time band 0 7

ES29 C Friday operation with domestic hot water time band 0 7

ES30 C Saturday operation with domestic hot water time band 0 7

ES31 C Sunday operation with domestic hot water time band 0 7

ES32 C Domestic hot water energy saving setting increase -30.0

-54

30.0

54

°C

°F

Dec

Int

ES33 C Domestic hot water differential in time band/digital input 0.1

0

25.0

45

°C

°F

Dec

Int

Pr1 U User password 0 999

Pr2 S Service password 0 999

Pr3 C Manufacturer password 0 999

Compressors plant

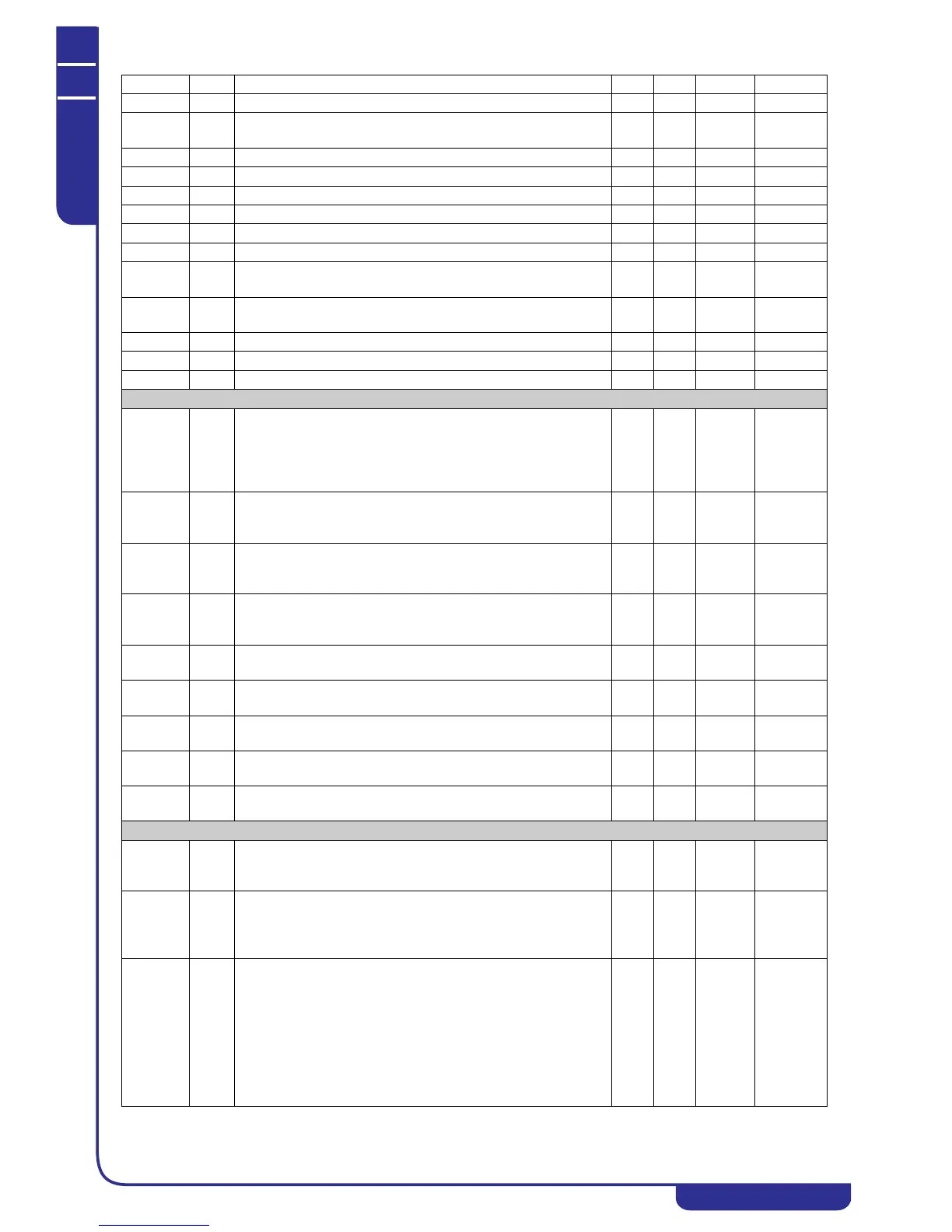

Cr01 C Defines the cooling plant temperature control type:

0= Disabled

1= Control with probe defined by ST09

2= Enabled with suction probe (evaporation) (condensing units

and heat pumps are automatically disabled)

02

Cr02 C Suction probe compressors setpoint (evaporation)

Makes it possible to program the working setpoint of the suction

probe

Cr03 Cr04 Bar

Psi

Dec

Int

Cr03 C Suction probe compressors minimum setting (evaporation)

Establishes the minimum limit that can be utilised to set the

suction probe working setpoint.

0 Cr02 Bar

Psi

Dec

Int

Cr04 C Suction probe compressors maximum setting (evaporation)

Establishes the maximum limit that can be utilised to set the

suction probe working setpoint.

Cr02 50

725

Bar

Psi

Dec

Int

Cr05 C Control steps activation band of suction probe. 0.1

1

14.0

203

Bar

Psi

Dec

Int

Cr06 C Energy saving setting increase in cooling plant mode. 0.0

0

14.0

203

Bar

Psi

Dec

Int

Cr07 C Energy saving differential in cooling plant mode. 0.1

1

14.0

203

Bar

Psi

Dec

Int

Cr08 C No. of compressors to start in case of fault of probe allocated for

their control 0 ... 6

06

Cr09 C No. of condensing fan steps of the circuit to activate in case of

fault of probe allocated for their control 0 ... 4

04

Compressor

CO01 C Compressor minimum run time.

Establishes the time during which the compressor must run after

being starting, even if the demand drops.

0 250 10 Sec 10 Seconds

CO02 C Compressors minimum stop time.

Establishes the time during which the compressor must remain

stopped, even if restarting is requested.

During this period the compressor LED will flash.

0 250 10 Sec 10 Seconds

CO03 C Time lag between starts of 2 compressors / capacity steps.

With two compressors, establishes the starting time lag between

the two in order to limit starting peak current.

During this period the compressor LED will flash (only for the

compressor).

With unit having one capacity controlled compressor.

Establishes the activation time of the capacity control solenoid

for a start at minimum capacity (see heading “7.15.1 Compressors

control”).

1 250 Sec

Parameter Level Description Min. Max. UM Resolution

Loading...

Loading...