OPERATING AND MAINTENANCE MANUAL

Chapter 7 - Electronic controller

TAEevo Tech 015÷802 60 Hz UL

84

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

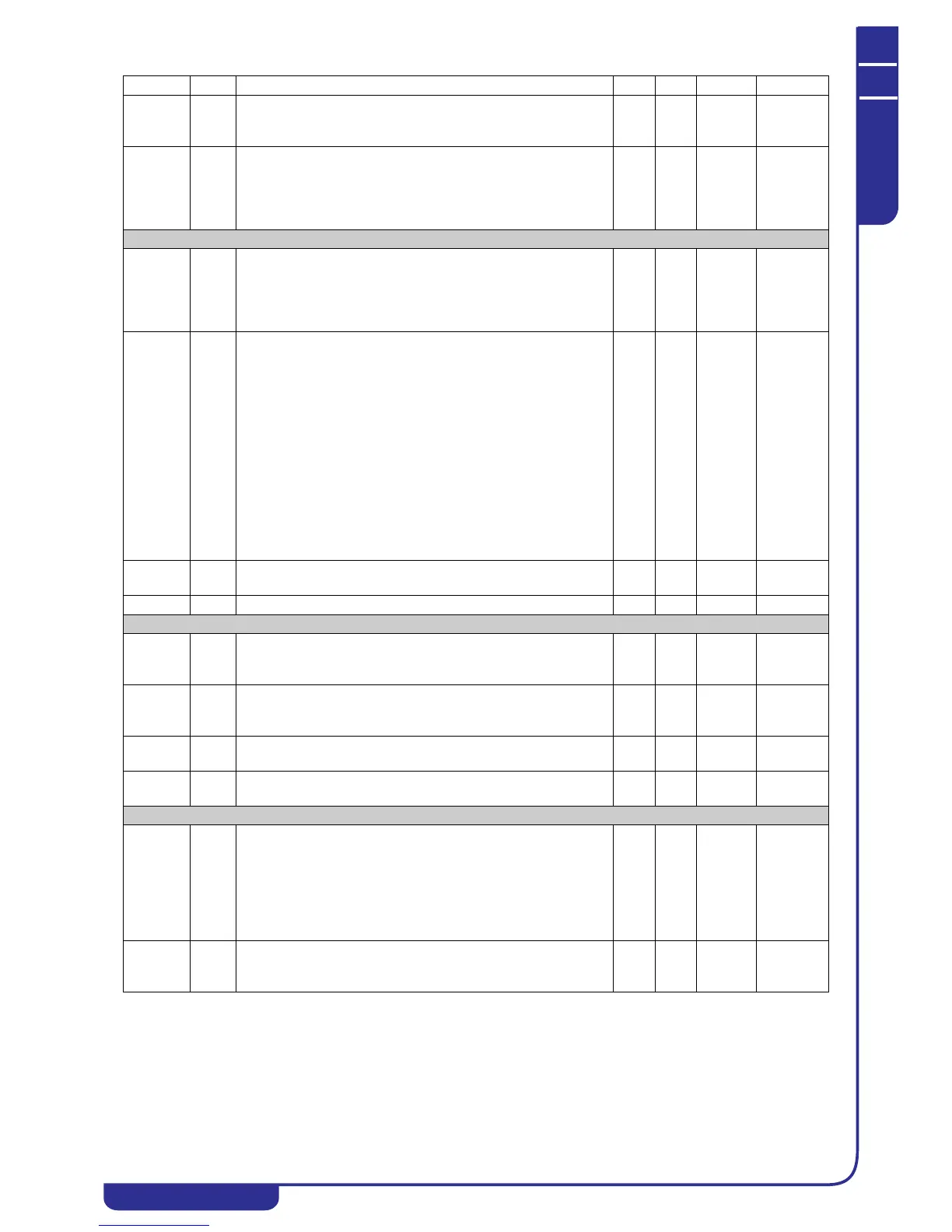

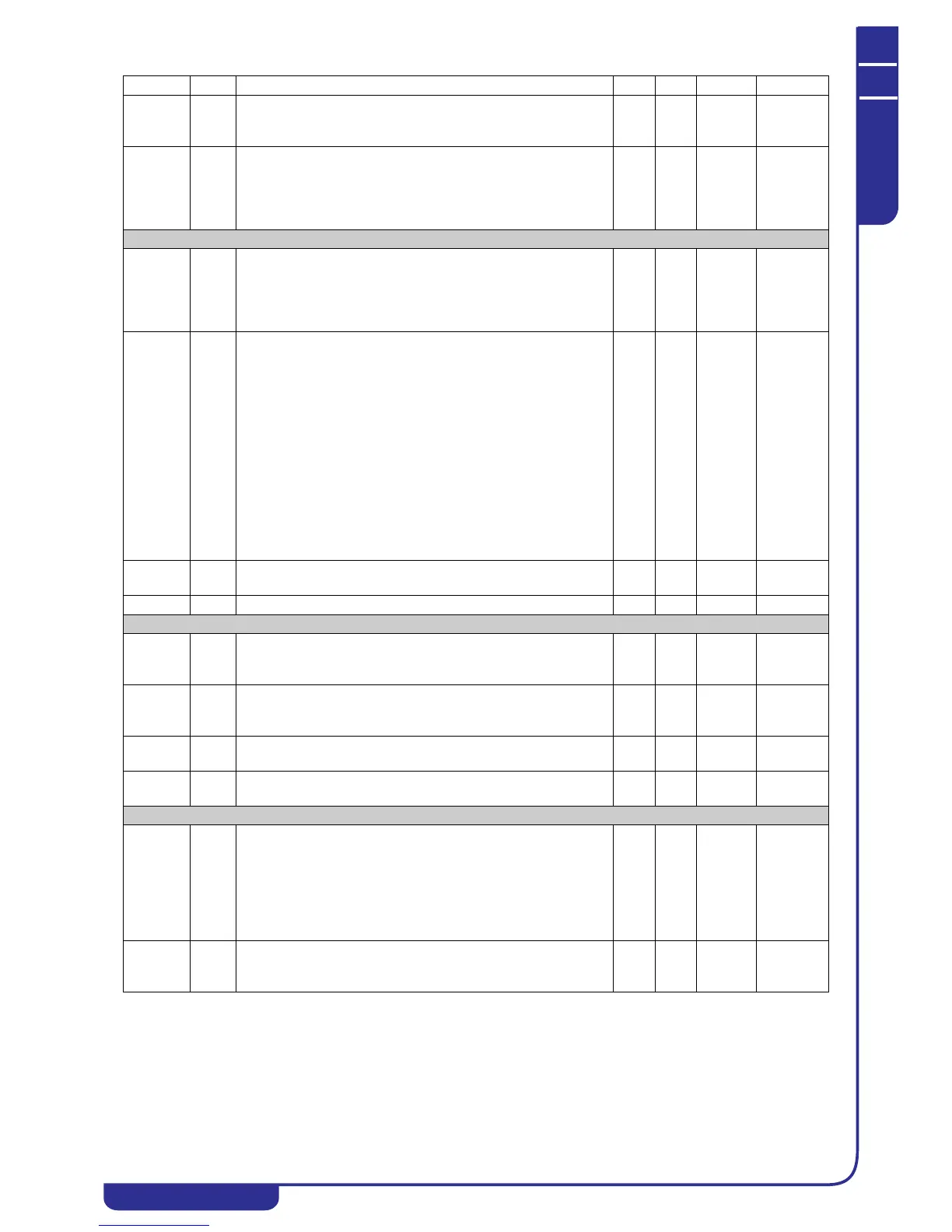

CO04 C Time lag between stops of 2 compressors / capacity steps.

Establishes the stopping time lag between two compressors or

two capacity steps.

0250Sec

CO05 C Delay at compressors starting from power ON.

Starting construed as physical power-up of the controller.

Delays activation of all the outputs to distribute current draw and

protect the compressor(s) from repeated starts in the event of

frequent mains power losses.

0 250 10 Sec 10 Seconds

Capacity controls (INACTIVE FUNCTION)

CO06 C Capacity controls operation:

0= ON/OFF steps control

1= Direct action continuous run with capacity steps

2= Reverse action continuous run with capacity steps

3= Global continuous capacity step control

03

CO07 C Enabling for operation of minimum compressor capacity /

unloaded starting management:

0= Enables minimum capacity only at compressor start (start with

minimum capacity / unloaded starting with valve OFF and

compressor stopped)

1= Enables minimum capacity only at compressor start and during

temperature control (start with minimum capacity / unloaded

starting with valve OFF and compressor stopped)

2= Screw compressors, enables minimum capacity only at

compressor start (start with minimum capacity / unloaded starting

with valve ON and compressor stopped)

3= Screw compressors, enables minimum capacity at compressor

start and during temperature control (start with minimum capacity

/ unloaded starting with valve ON and compressor stopped)

03

CO08 C Screw compressor intermittent valve control relay ON time; if

parameter value is 0 the function is disabled.

0250Sec

CO09 C Screw compressor intermittent valve control relay OFF time. 0 250 Sec

Compressor starting

CO10 C Compressor starting (see heading “7.15.1 Compressors control”):

0= Direct

1= Part-winding

01

CO11 CIf CO10=1 part-winding starting time. Used to vary the

energization of the two different relays that feed the two motor

windings.

0 100 Dec Sec 0.1 Sec

CO12 C Time for which condensation fan thermal protection switch is

bypassed after controller power on

0250Sec

CO13 C Run time with gas by-pass valve / compressor unloaded starting

valve (see capacity controls operation).

0250Sec

Compressors rotation - balancing - temperature control

CO14 S Compressors rotation (see heading “7.15.6 Compressors

rotation”):

0= Fixed sequence

1= Rotation enabled with compressors temperature control on

basis of running hours

2= Rotation enabled with compressors temperature control on

basis of starts/hour (peak loads)

02

CO15 S Circuits balancing:

0= Circuits saturation

1= Circuits balancing

01

Parameter Level Description Min. Max. UM Resolution

Loading...

Loading...