9-60

“Confidential, Do Not Duplicate without written authorization from NEC.”

ASSEMBLY DIAGRAM

Diagram symbol Circuit symbol Part name Part code Q’ty Remarks

PRT1 SHIELD CASE E 24H61041 1

PRT2 CAM(LOCK)TI 24H61071 1

PRT3 KEY(NS-804) 24C09301 1 Number control

PRT4 NUT(larg) 1 Torque check

PRT5 NUT (small) 1 Torque check

PRT6 WASHER 1 1

PRT7 WASHER 2 1

PRT8 BRACKET(P-FAN) 24H60851 1

PRT9 DCFAN 9BAM24GD2-2 3N170100 1

SRW110 PL-CPIMS*4*10*3KF 24V00461 2 Torque check

SRW058 PL-CPIMS*4*10*3KF 24V00461 2 Torque check

TI Shield MT4

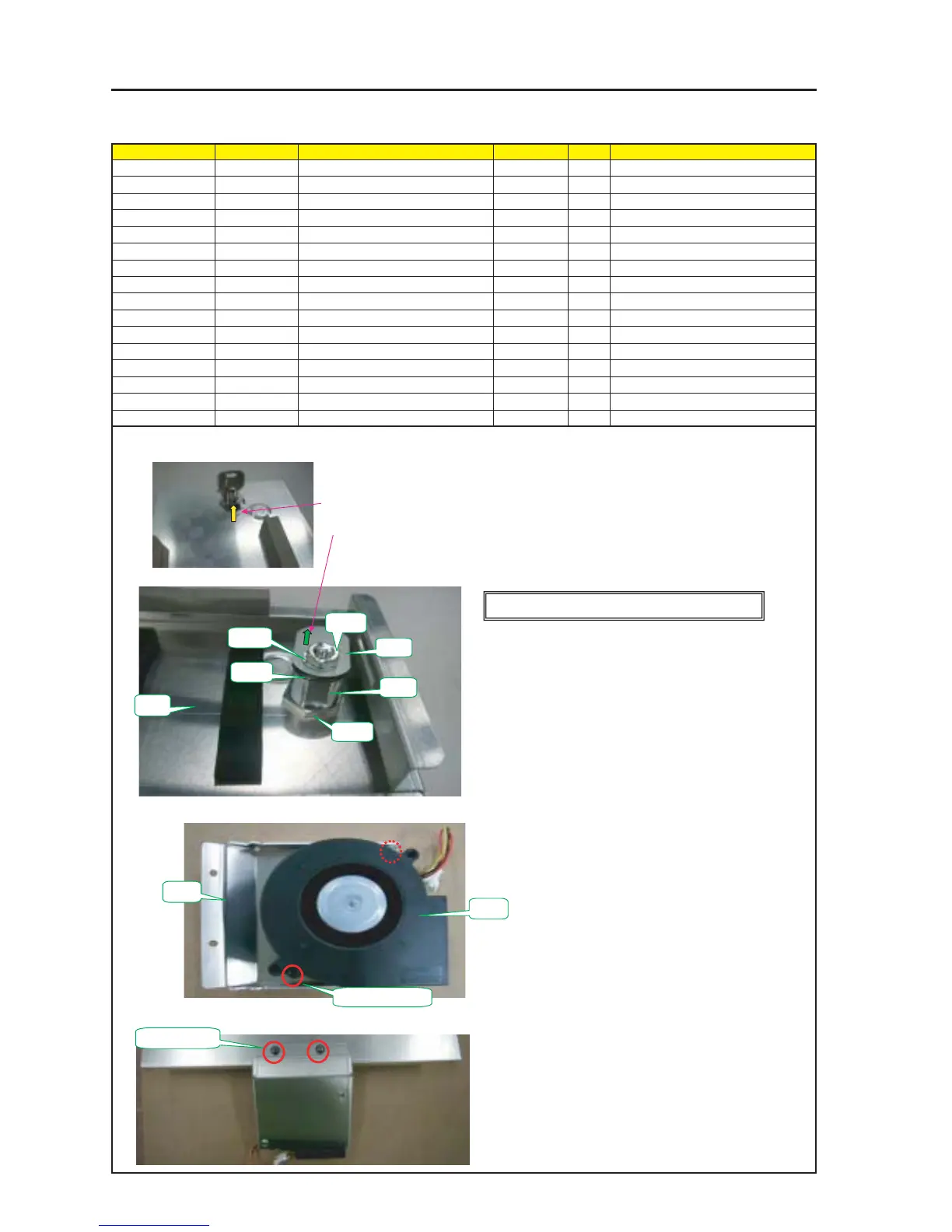

1 Mount the KEY (NS-804) and the CAM (LOCK) TI on the Shield Case E.

For the installation of the CAM (LOCK) TI, the nuts attached to the KEY (NS-804) shall be used.

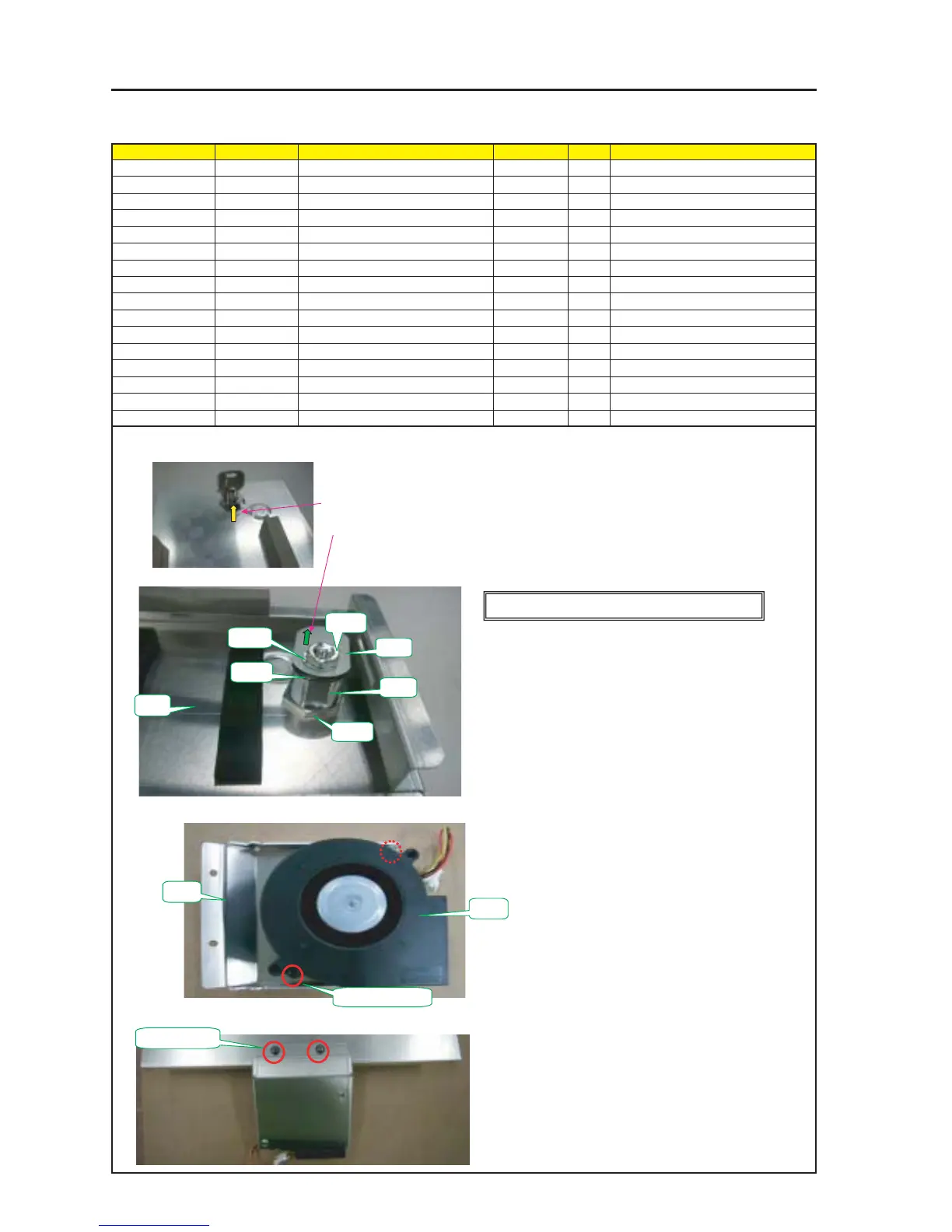

3 Mount the DC FAN 9BAM24GD2-2 on the BRACKET (P-FAN).

4 Mount the DC FAN Sassy on the Shield Case E Sassy.

PRT4

PRT7

PRT5

PRT6

PRT8

PRT9

SRW110 X 2P

SRW058 X 2P

PRT1

PRT2

PRT3

[Caution] Describe the KEY number in the history sheet.

The CAM (LOCK) TI shall be installed in the posture as shown in the photo below.

2 In the state that the key is inserted (Unlocked), the notch section shall be positioned inside.

a) Remove the nut and washer, attached to the KEY (NS-804).

b) With the NUT (large), fix the KEY (NS-804) to the Shield Case E.

c) Enter the Washer 1 and the CAM (LOCK) TI in the KEY (NS-804).

d) Enter the Washer 2 and fix the CAM (LOCK) TI with the NUT (small).

Tightening torque of PRT4 : 100±5kgf•cm

Tightening torque of PRT5 : 32±2kgf•cm

Caution : Confirm that the key can be pulled out after key locking.

If it cannot be pulled out, change the direction of washer

attached to the key and reinstall it.

Loading...

Loading...