SECTION 6

TROUBLESHOOTING

98

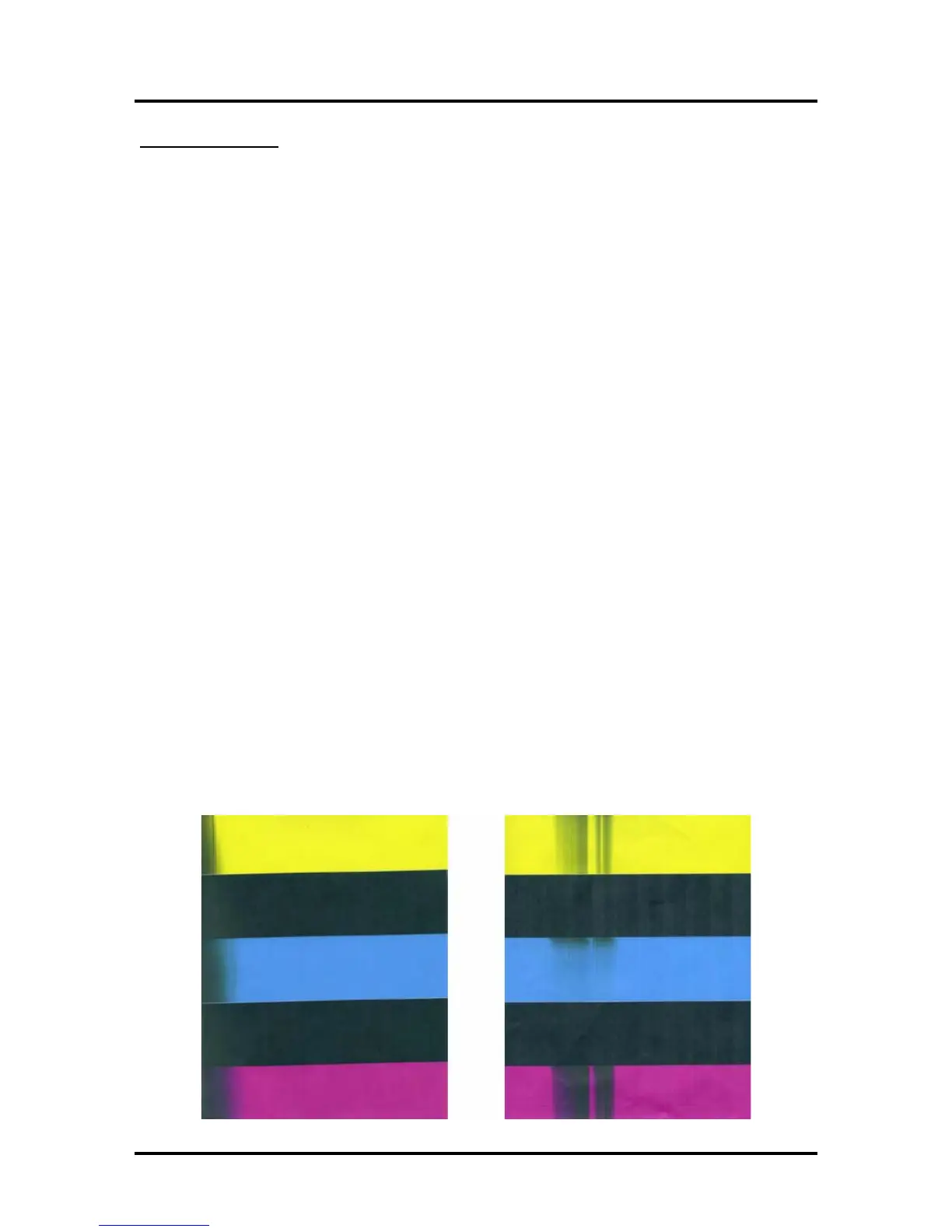

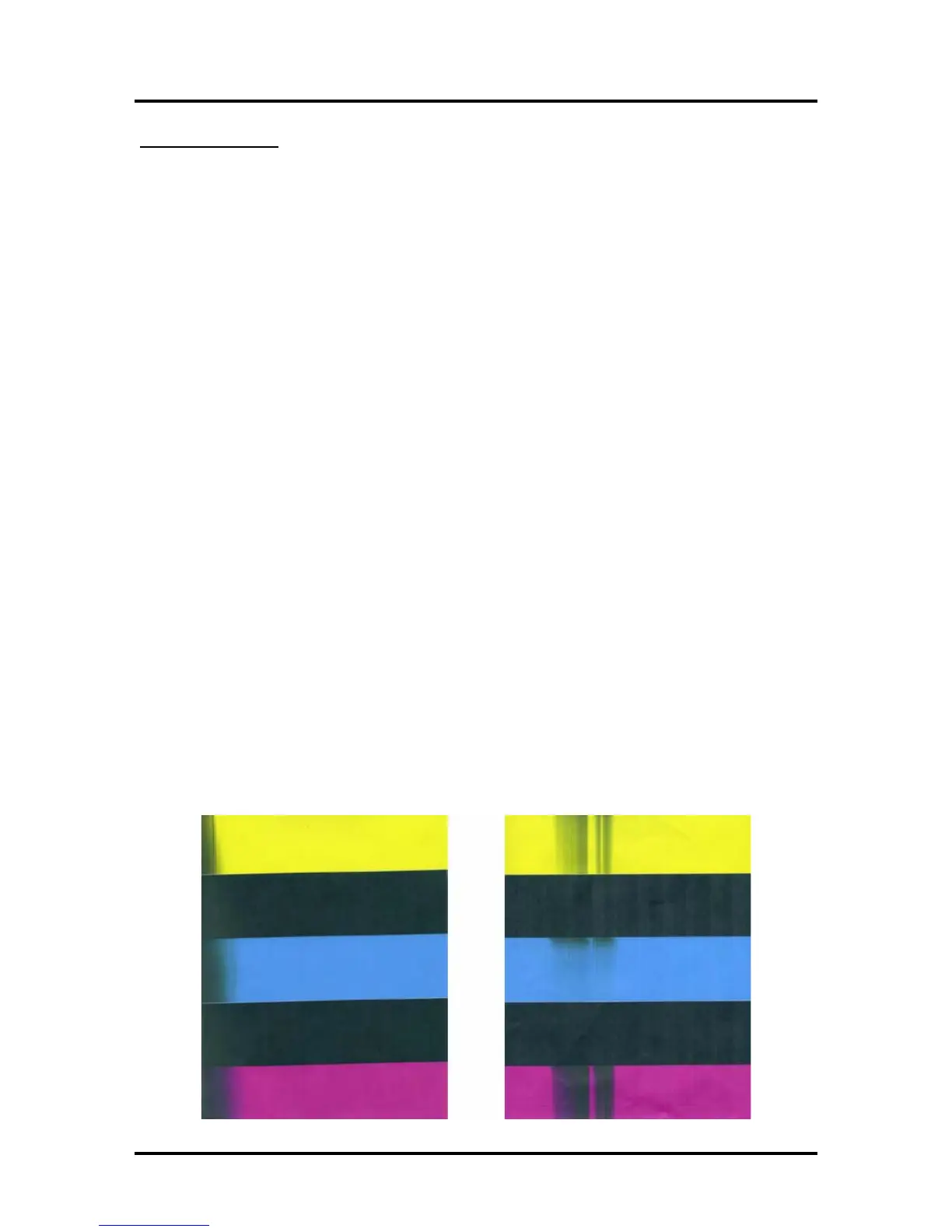

Color Mixing Issues:

Color mixing will show as muddy, mottled or distorted (grainy) colors.

Color mixing occurs when the ink from one color channel crosses over into another color channel. Since

the inkjet nozzle rows are located very close to one another (ten rows of 7,040 nozzles, located within a 0.8

mm space), it is easy for partials or fibers to create bridges across color channels. These bridges allow ink

to flow (wick) from one color channel to another; resulting in a “localized” color mixing event; as shown in

the examples below.

Color mixing can occur for a number of reasons (here are some common ones)

• Printhead Cartridge just installed. It is common to see some color mixing immediately after the

system is primed with ink.

• Ink wicking due to fibers bridging (crossing) inkjet nozzles. This can also occur if media is left in

contact with the printhead (after a paper misfeed or jam).

• Wiper roller saturation (too much ink on wiper roller). This can occur if the cleaning features

(Quick/Normal/Full Clean Printhead) are run too frequently. The printer needs time between

cleanings to desiderate the wiper roller.

• Ink flooding on the nozzle plate; due to printer not being level.

• Ink flooding on the nozzle plate; due to excessive back-pressure in the ink system.

• Wiper Roller is not being cleaned properly by the system. This can also occur if there is a

problem with the squeegee blade in the Wiper Motor Assembly. The squeegee blade and

squeegee roller are responsible for removing ink and debris from the wiper roller.

Tip: Muddy, mottled, distorted (grainy) colors can also be caused by the media you are printing onto.

Test the printer, using a compatible “inkjet suitable” media, to determine if this could be the cause.

Possible Solutions:

• Remove media from under printhead.

• Wipe printhead using a lint-free cloth, dampened with distilled water.

• Perform a “Printhead Cartridge Conditioning” routine.

• Allow the printer to sit, powered on, for 2-3 hours to give it time to clean/desaturate the wiper

roller.

• Make sure printer is on a sturdy, level table.

• Instead of powering the printer off, when not in use, leave the print engine powered-up; so it can

perform automatic maintenance routines. This also allows the pressures in the system to be

routinely equalized.

• Contact Service Support representative to have them inspect/clean the service station. If necessary;

they may need to replace the wiper roller, wiper motor assembly or Service Station.

Loading...

Loading...