SECTION 5

MAINTENANCE

91

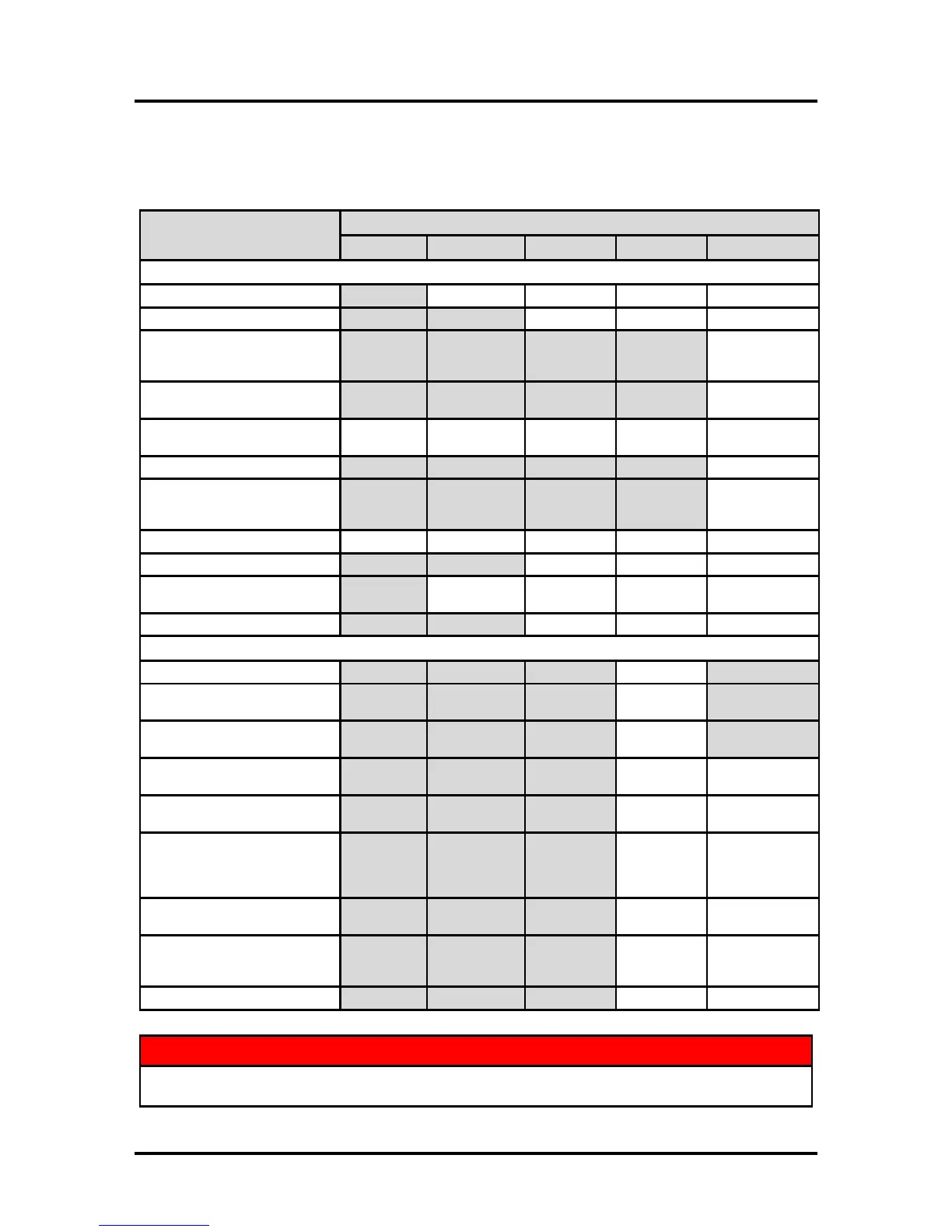

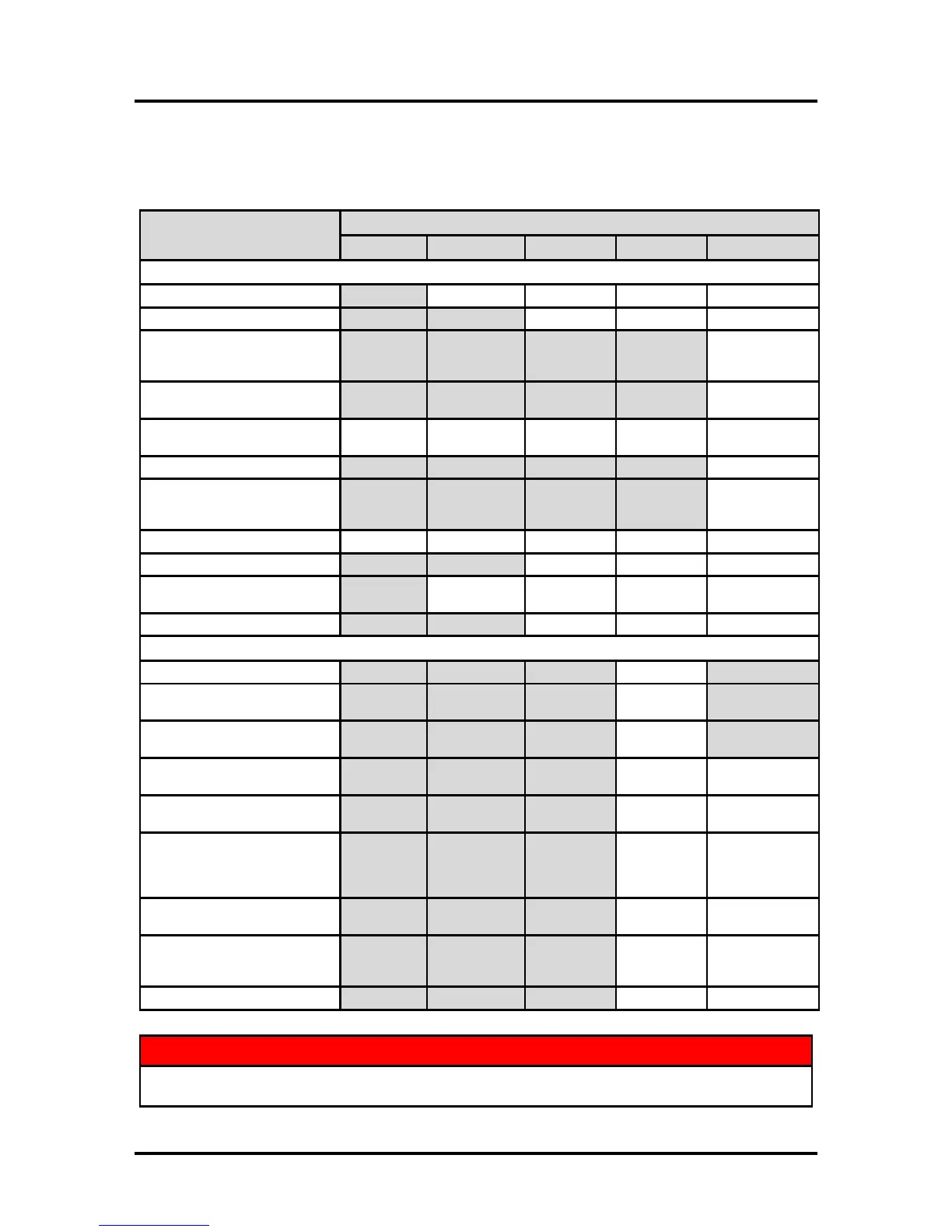

PRINTER MAINTENANCE SCHEDULE

General, periodic maintenance is needed to keep the Printer in good working order. Many tasks can be

performed by operators with basic supplies, no special tools needed. Other tasks should only be performed

by trained service personnel. NOTE: High volume usage may require more frequent maintenance.

COMPONENTS / TASKS

MAINTENANCE TYPE

DAILY BI-WEEKLY MONTHLY YEARLY AS NEEDED

PERFORMED BY OPERATOR

Rubber Feed Rollers CLEAN CLEAN CLEAN CLEAN

Grit Rollers (Media Path) INSPECT CLEAN CLEAN

Ink Revolver Couplings and

Connections:

Inspection/Cleaning

EVERY

PRINTHEAD

REMOVAL

Ink Tank Contacts & Prism

(Clean)

EVERY INK

TANK INSTALL

Optical Sensors

(Media Feed & Paperpath)

CLEAN CLEAN CLEAN CLEAN CLEAN

Printhead (Manual Wiping) WIPE

Printhead, Head Media Guide

& Lip of Capping Station

(Manual Wiping)

AFTER EVERY

PRINTHEAD

INSTALL

Residue and Debris Removal

Sheet Separators INSPECT INSPECT REPLACE

Wiper Roller:

Inspection

INSPECT INSPECT INSPECT

Contact Service

to Replace

Waste Ink Tray INSPECT INSPECT REPLACE

PERFORMED BY SERVICE TECHNICIAN

Ink Tank Latches/Ink Bay INSPECT

Ink Tubing, Couplings,

Components

INSPECT

Lubrication (Service Station

Rails, Lift Arm Cams, etc..)

APPLY

Moving Parts/Motors/Gears

INSPECT

& TEST

REPLACE

Optical Sensors (Service

Station Home, Index and Lift)

INSPECT &

TEST

CLEAN

*Pen Driver PCA Contacts:

Cleaning

INSPECT &

CLEAN

INSPECT/

CLEAN AFTER

PRINTHEAD

REMOVAL

*Service Station &

Components

INSPECT

CLEAN or

REPLACE

*Wiper Roller:

Replace

INSPECT

EVERY

PRINTHEAD

REPLACEMENT

Rubber Feed Rollers INSPECT REPLACE

* Customer may be able to perform these tasks with proper training.

ALWAYS POWER DOWN THE PRINTER BEFORE PERFORMING ANY MAINTENANCE; TO AVOID

SERIOUS SHOCK OR INJURY.

Loading...

Loading...