5238-E P-135

SECTION 7 FIXED CYCLES

This M code is cleared by the reset operation and it is effective only in the specified block.

An M code is given priority over the optional parameter setting.

When no M code is designated, the optional parameter setting becomes effective.

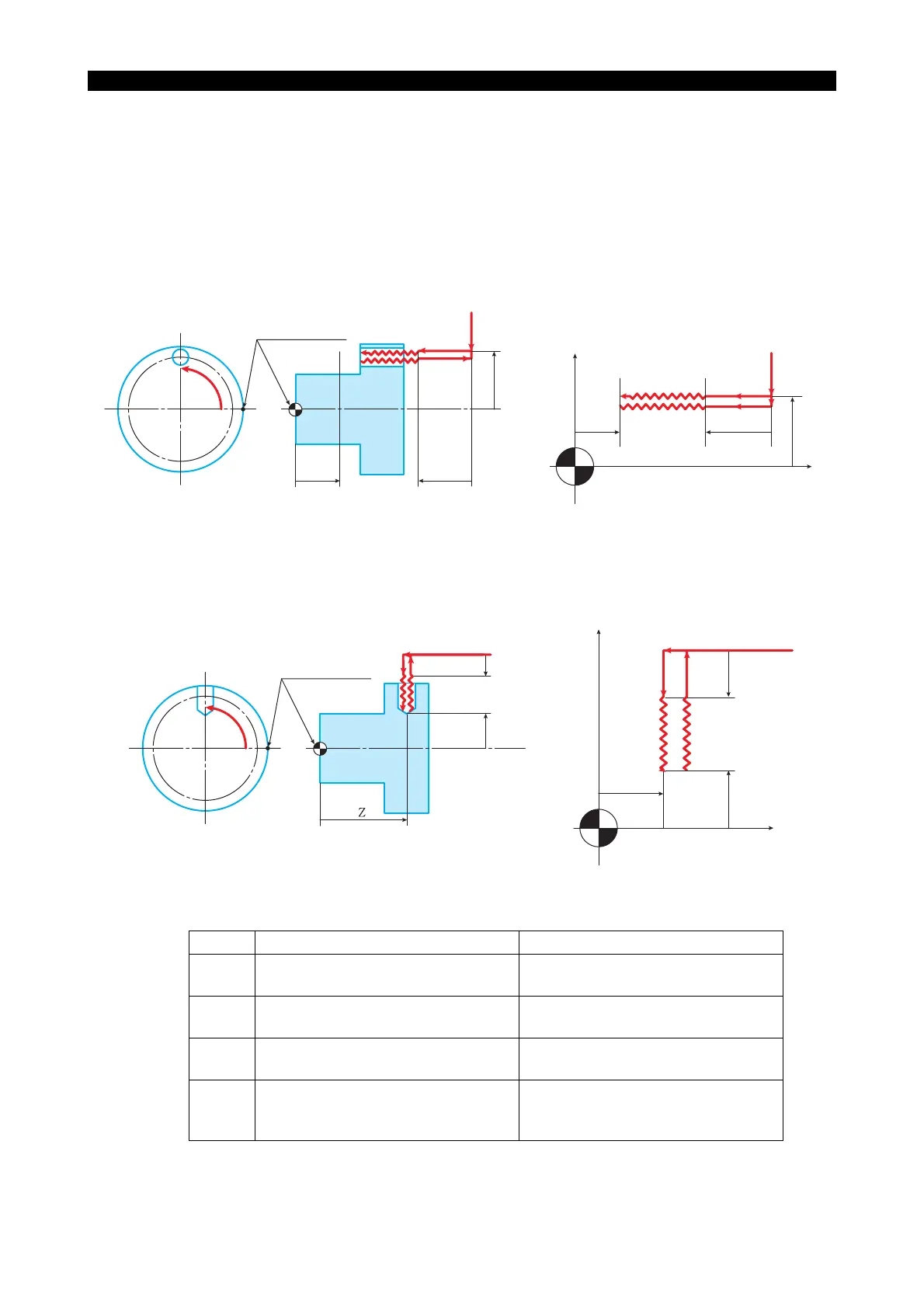

• The basic axis motions of the tapping cycle (G184), synchronized tapping cycle (G178/G179),

and milling/boring cycle (G189) are shown below when the setting for the optional parameter

indicated above is "1" or if an M136 command exists in the program.

Face Machining (With K command)

LE33013R0300900280003

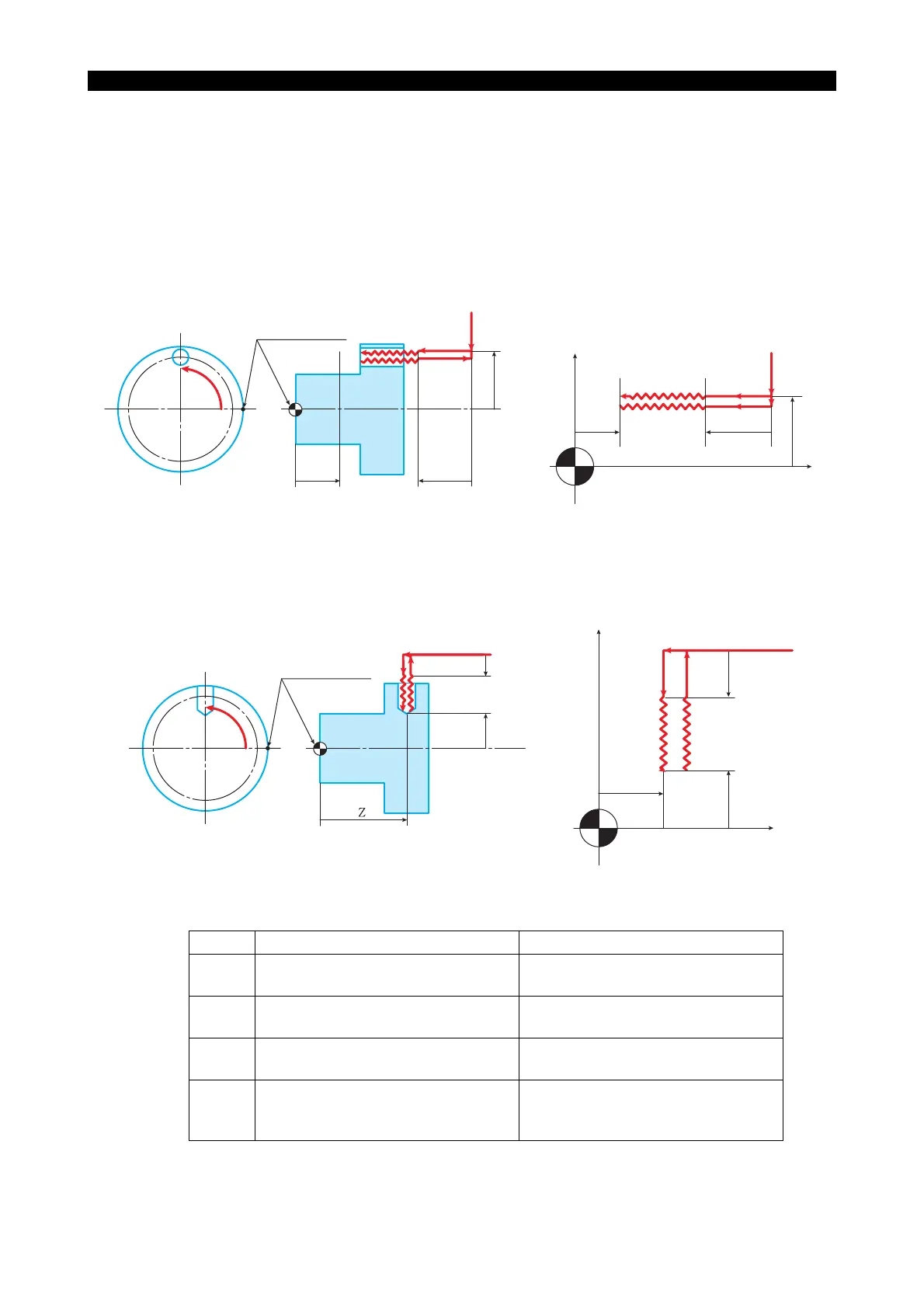

Side Machining (With I command)

LE33013R0300900280004

Face Machining (With K command) Side Machining (With I command)

Q

1

Positioning of X- and C-axis at the

rapid feedrate

Positioning of Z- and C-axis at the

rapid feedrate

Q

2

Positioning of Z-axis at the point

"Q1 - K" at the rapid feedrate

Positioning of X-axis at the point

"Q

1

- I" at the rapid feedrate

Q

3

Cutting along Z-axis from point Q

2

to

the commanded point Z

Cutting along X-axis from point Q

2

to

the commanded point X

Q

4

X-axis returns to Q

3

where cutting

started at a cutting feedrate and then

to Q

2

at the rapid feedrate.

X-axis returns to Q

3

where cutting

started at a cutting feedrate and then

to Q

2

at the rapid feedrate.

C90°

C0°

(Diagram)

Program zero

Q

2

Q1

Q3

Q4

Q2

Q1

Q3

Q4

X/2

X/2

K

K

C

Z

Z

(Actual Example)

C90°

C0°

(Diagram)

Program zero

Q

2

Q1

Q3

Q2

Q1

Q3

Q4

X/2

I/2

X/2

I/2

C

Z

Z

(Actual Example)

Loading...

Loading...