5238-E P-136

SECTION 7 FIXED CYCLES

• C-axis clamp effective/ineffective command

When the workpiece is cut using a small-diameter drill in the compound fixed cycle, or when the

material to be cut is soft, the C-axis does not need to be clamped during cutting.

When M141 (C-axis clamp ineffective) is designated, C-axis clamp motion is eliminated,

resulting in a reduced cycle time.

M169 is only effective within one block.

• Ignoring the M-tool constant speed rotation answer for M140 (tapping cycle)

In the tapping cycle, cutting feed starts after receiving the M-tool constant speed rotation

answer. Because of this, a time lag occurs between the start of tool rotation and the start of

cutting feed. Normally, the time lag is adjusted by a mechanism in the tapping unit. If the time

lag cannot be adjusted, designate M140 (ignoring the M-tool constant speed rotation answer).

The M-tool constant speed rotation answer is ignored.

8-2-2. G190 mode

In this mode, the following cycle is carried out in a single block of commands.

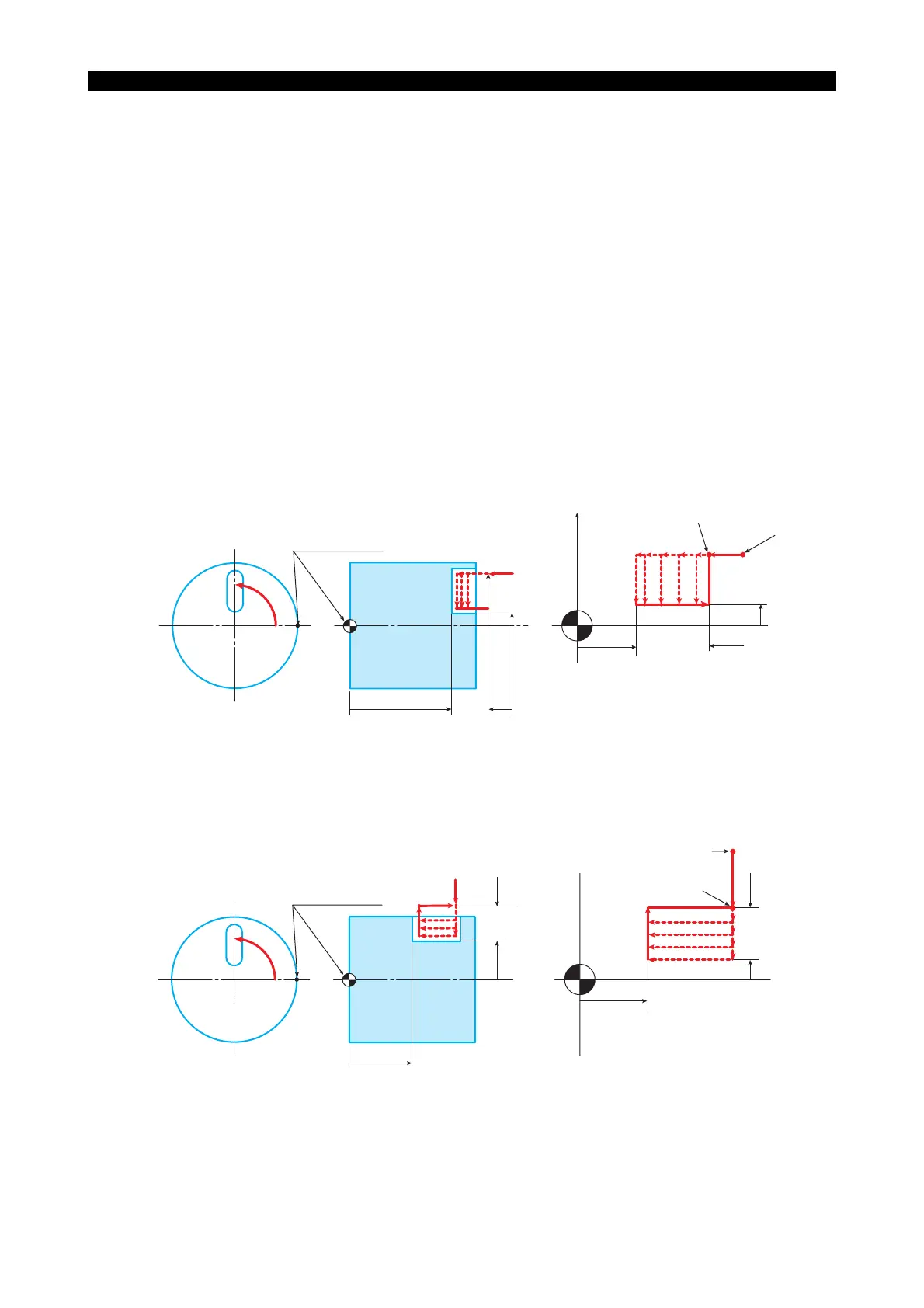

Face Machining (With K command)

LE33013R0300900290001

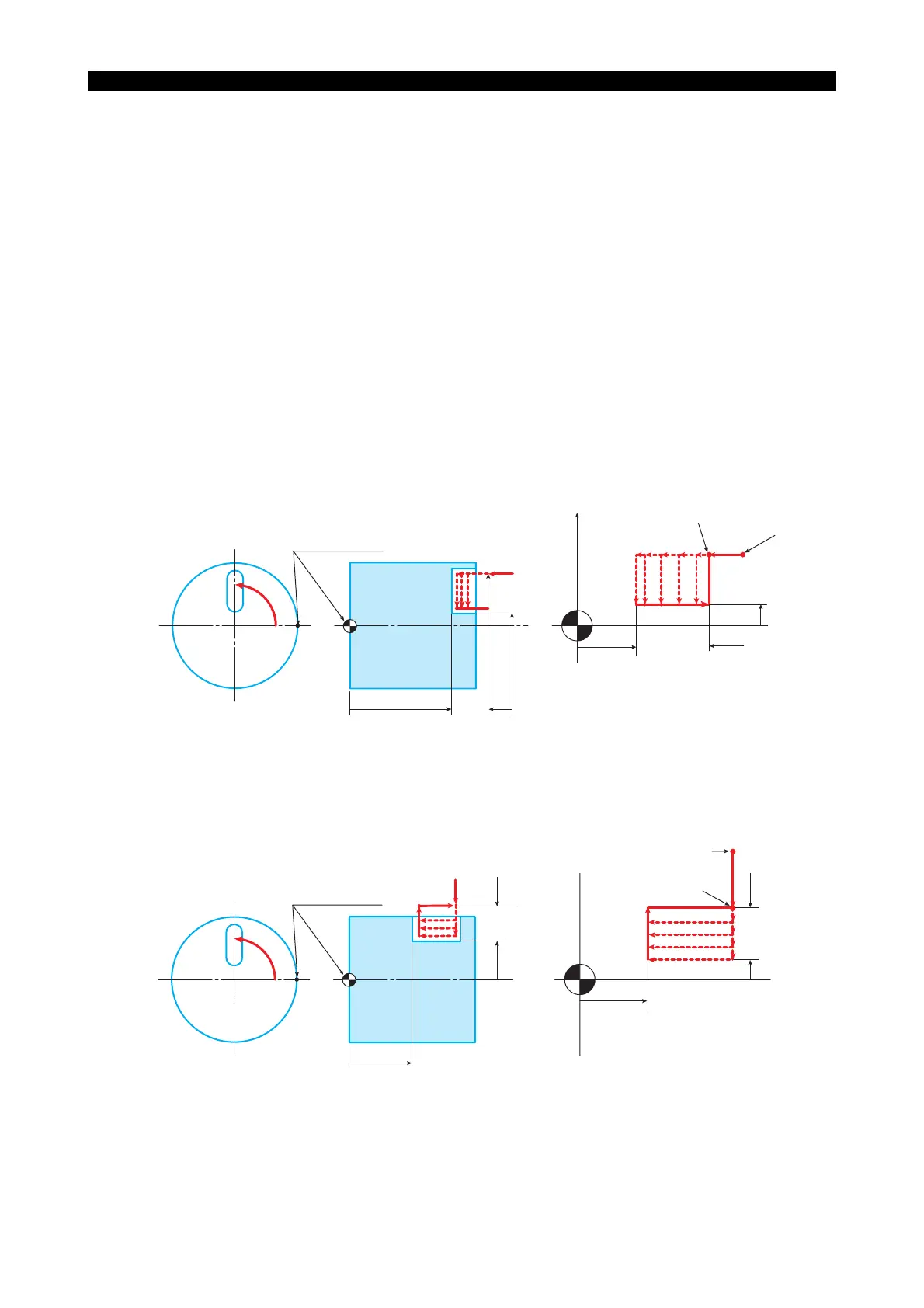

Side Machining (With I command)

LE33013R0300900290002

C90°

C0°

(Diagram)

Program zero

Q

2

Q3

Q4

Q4

Q2

Q1

Q1

Q3

Cutting starting point

X/2

Z

Z

K

X

K

(Actual Example)

Starting point

C90°

C0°

(Diagram)

Program zero

Q

2

Q3

Q4

Q2

Q1

Q3

Q4

Cutting starting point

X/2

I/2

X/2

I/2

Z

Z

(Actual Example)

Starting point

Loading...

Loading...