AIR

CONDITIONER

NOTICE:

Have

a thorough service inspection

performed before using your air conditioner

at the beginning

of

the cooling

season,

or

as

suggested as follows:

• Check refrigerant and add

as

necessary.

Over

the period of a year, the system

may

lose

refrigerant through normal

operation.

• Check and adjust compressor belt

tension.

•

Remove

road accumulation from

condenser (bugs, etc.)

at

least every

2,000 miles

(3200

kilometres).

AIR

CLEANER

The air cleaner

is

a disposable type

element. Replace the element as specified

in the Maintenance Schedule folder.

Do

not wash, oil, or clean with air hose. The

air

cleaner will need more frequent

service

in

dusty conditions. Your Oldsmobile

dealer can advise you on the proper

interval.

When

replacement

is

necessary, an

AC

air filter element is recommended.

NOTICE:

If

the air cleaner is removed during

repair

or

maintenance, be

sure

toput

it back

66

on correctly. Without the air cleaner on, the

engine

may backfire and

cause

a fire

in

the

engine compartment.

BRAKE

MASTER

CYLINDER

Check the fluid

level

at each

oil

change

period.

Wipe

off the brake cylinder filler

cap

and

unsnap the four retainers. A

low

fluid

level

in the front brake master

cylinder reservoir could mean that the disc

brake pads need replacing. The fluid

level

must be kept

level

with the center divider.

Use

Delco Supreme No.

11

or DOT-3

Hydraulic Brake Fluid.

When

replacing the

cap, be

sure

to fasten the retainers

securely.

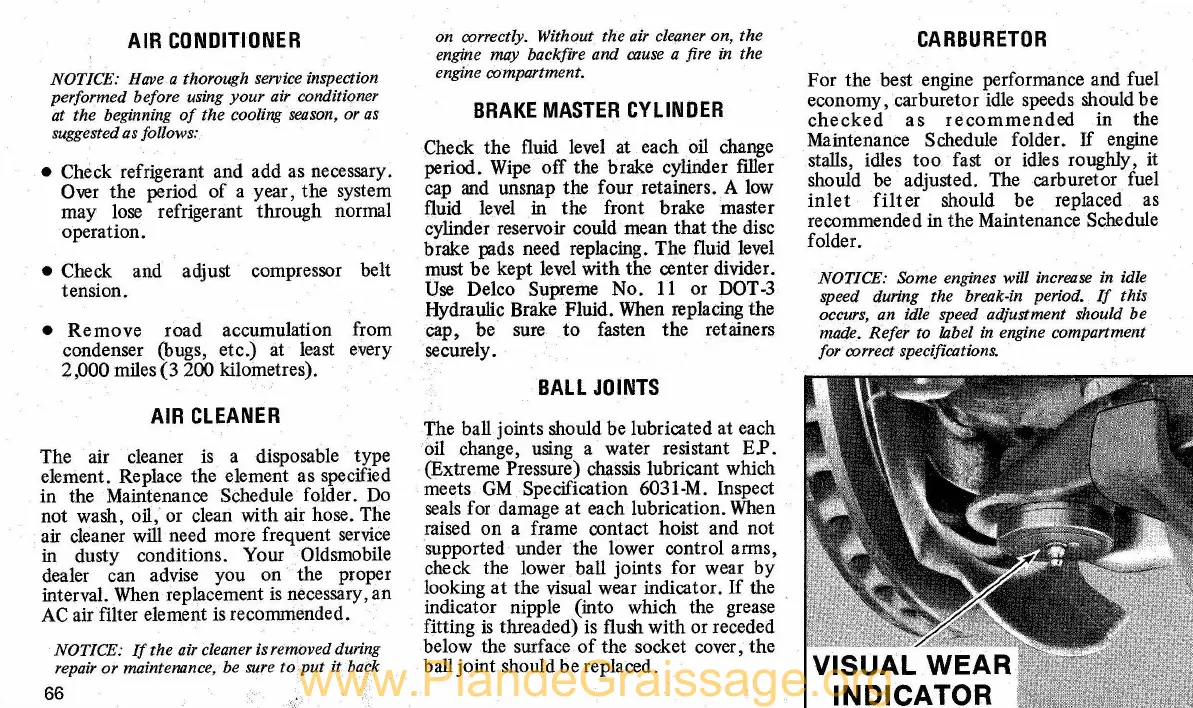

BALL

JOINTS

The ball joints should be lubricated at each

oil change,

using

a water resistant

EP.

(Extreme Pressure) chassis lubricant which

meets

GM

Specification 6031-M. Inspect

seals

for damage at each lubrication.

When

raised on a frame contact hoist and not

supported under the lower control arms

check the lower ball joints for wear

by

looking

at

the visual wear indicator.

If

the

~~cat?r

nipple (into which the

grease

flttmg IS threaded)

is

flush with or receded

below the surface

of

the socket

cover

the

ball joint should be replaced. '

CARBURETOR

For the best engine performance and fuel

economy, carburetor

idle

speeds should be

checked

as

recommended

in the

Maintenance Schedule folder.

If

engine

stalls, idles too fast or idles roughly, it

should

be

adjusted. The carburetor fuel

inlet

filter

should be replaced

as

recommended in the Maintenance Schedule

folder.

NOTICE: Some engines will increase in idle

speed during the break·in period.

If

this

occurs,

an

idle speed adjustment should be

maqe. Refer to lobe!

in

engine compartment

for correct specifications.

VISUAL WEAR

INDICATOR

Loading...

Loading...