• When the Drive Programming program is stopped, the data of the analog output terminal

variables before the program stop is retained. When the program execution is started again,

the process begins with the retained data. However, the outputs with the Drive Programming

not set are controlled as the inverter's analog outputs independently of the program.

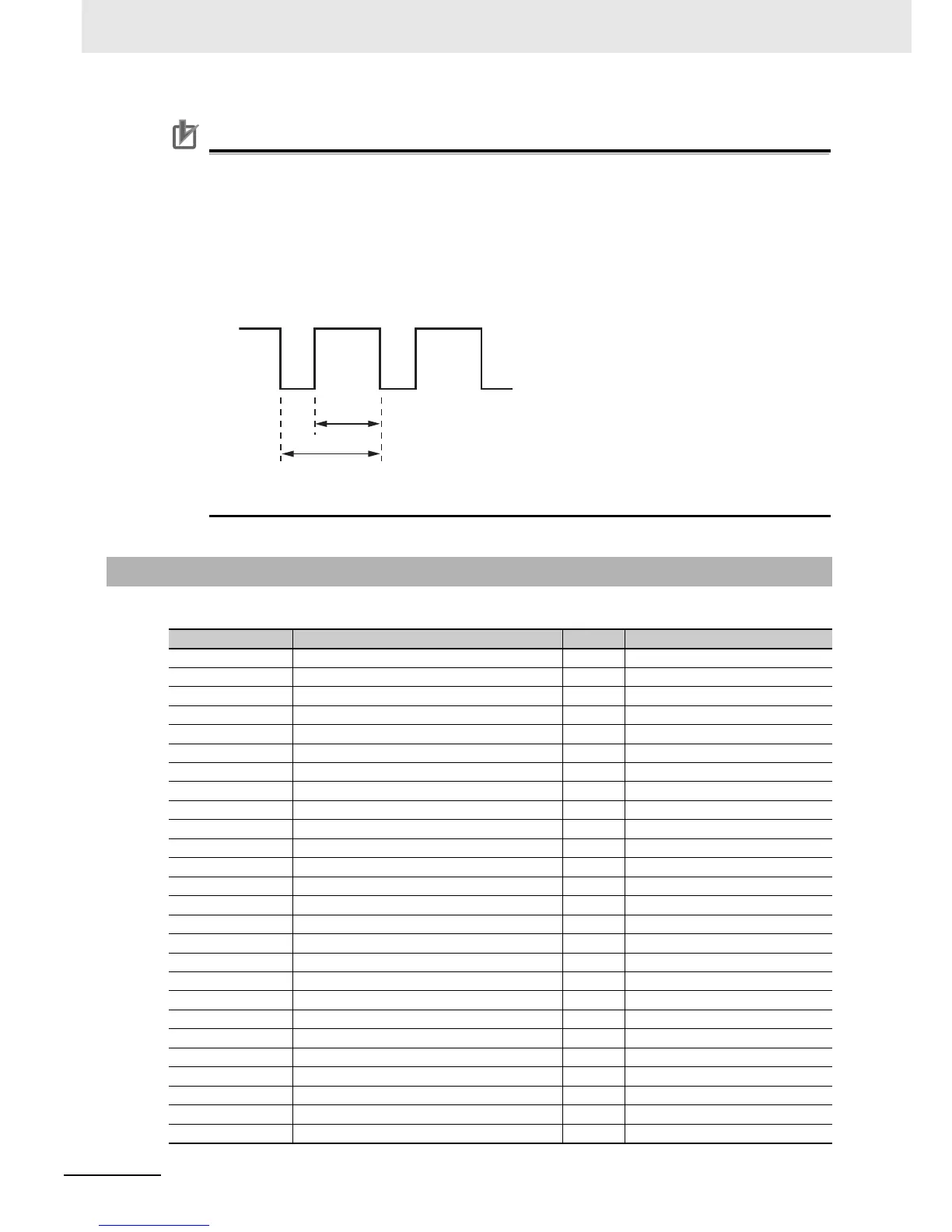

• The multi-function digital output (PWM output) FM terminal provides PWM signal outputs.

The terminal outputs the value of 0.00 to 100.00% (variable) as the pulse width (duty ratio

t/T) in a 6.4 ms cycle.

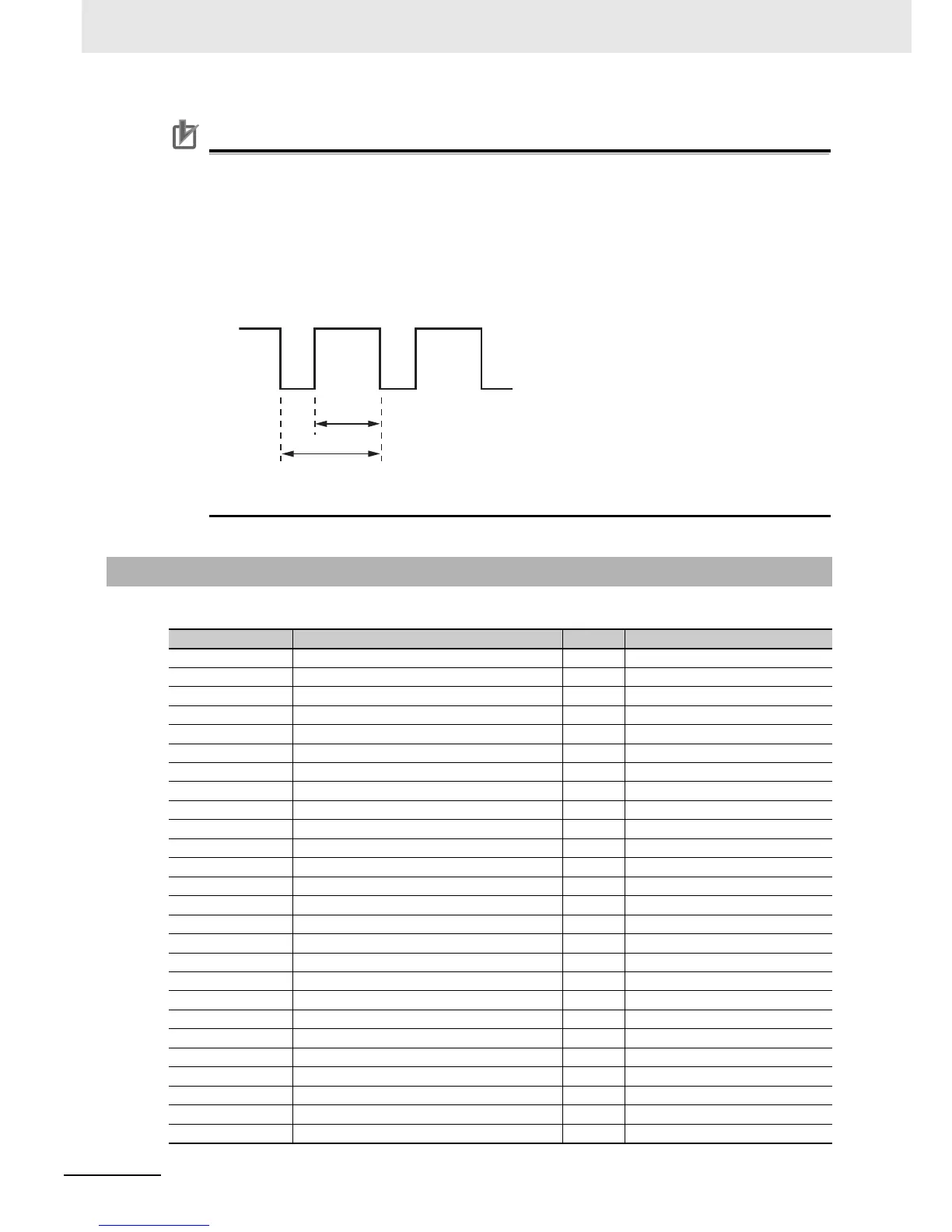

9-4-2 Multi-function Input Variables

Function variable Description R/W Reference

UP Upward RUN R/W C001 to C007 00

DWN Downward RUN R/W C001 to C007 01

SPD1 Multi-speed 1 setting R/W C001 to C007 02

SPD2 Multi-speed 2 setting R/W C001 to C007 03

SPD3 Multi-speed 3 setting R/W C001 to C007 04

SET 2nd Control R/W C001 to C007 08

FRS Free-run stop R/W C001 to C007 11

EXT External trip R/W C001 to C007 12

SFT Soft lock R/W C001 to C007 15

RS Reset R/W C001 to C007 18

OLR Change OL-level R/W C001 to C007 32

TL Torque limit enable R/W C001 to C007 33

TRQ1 Change Torque limit 1 R/W C001 to C007 34

TRQ2 Change Torque limit 2 R/W C001 to C007 35

PCLR Clear the current position R/W C001 to C007 40

KHC Kwh clear R/W C001 to C007 46

X(00) to X(11) Drive Programming MI1 to MI12 R/W C001 to C007 49 to 60

EMP Em-Power operation R/W C001 to C007 61

INSP Inspection R/W C001 to C007 62

RL Releveling R/W C001 to C007 63

COK Contactor check signal R/W C001 to C007 64

BOK Brake check signal R/W C001 to C007 65

FP1 to FP6 Floor position 1 to 6 R/W C001 to C007 66 to 71

PAL Auto learning data latch trigger R/W C001 to C007 72

TCL Torque bias latch trigger R/W C001 to C007 73

LVS Levelling signal R/W C001 to C007 74

t

T

Loading...

Loading...