RCCK

Fuel

System

GENERAL

Satisfactory engine performance is largely aepen-

dent upon correct fuel system adjustments. However,

adjustments cannot fully compensate for low engine

power due to wear, etc.

If

trouble develops, follow an

orderly procedure to determine the cause before

making any adjustment.

Adjusting the carburetor is a means of obtaining the

correct fuel-to-air mixture for smooth, efficient

operation. Always adjust in two steps, first the load

adjustment and then the idle adjustment.

GASOLINE CARBURETORS

Before adjusting the carburetor, be sure the ignition

system is working properly and the governor is

adjusted. Allow the engineto warm-up before starting

carburetor adjustments.

If

carburetor is completely out

of

adjustment

so

the engine will not

run, open both valves

1

to

1-112

turns off their seats to permit

starting.

Do

not force the needlevalves against theirseats.This can

bend the needle.

.-

.-

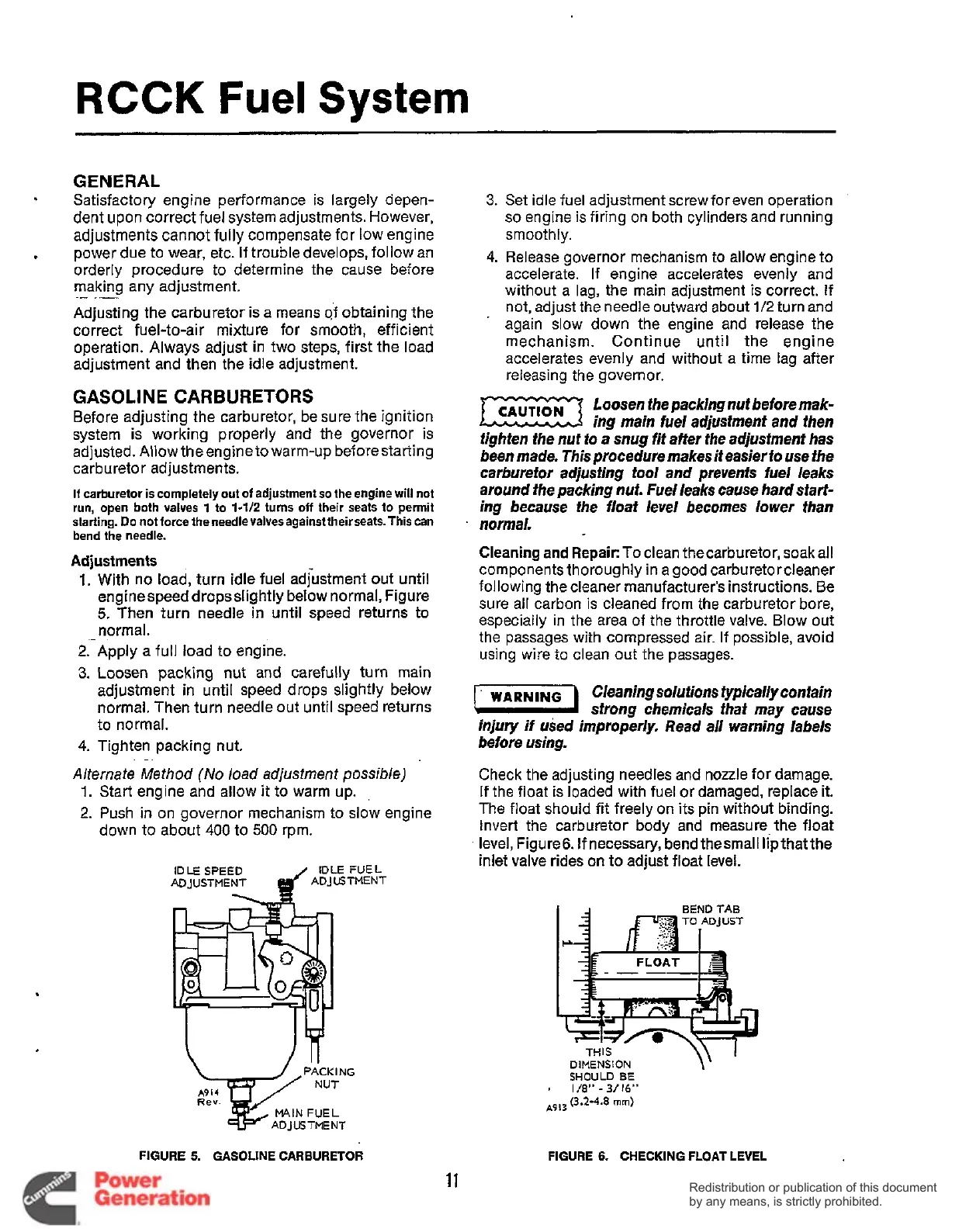

Adjustments

1.

With

no

load, turn idle fuel adiustrnent out until

enginespeed dropsslightly below normal, Figure

5.

Then

turn

needle in until speed returns

to

normal.

2.-Apply a full load to engine.

3.

Loosen packing nut and carefully turn main

adjustment in until speed drops slightly below

normal. Then turn needle out until speed returns

to normal.

4.

Tighten packing nut.

Alternate Method

(No

load adjustment possible)

1.

Start engine and allow it to warm up.

,

2.

Push in on governor mechanism to slow engine

.

_.

down to about

400

to

500

rpm.

3.

4.

Set idle fuel adjustment screw for even operation

so

engine is firing on both cylinders and running

smoothly.

Release governor mechanism to allow engine

to

accelerate. If engine accelerates evenly and

without a lag, the main adjustment is correct. If

not, adjust the needle outward about

1/2

turn and

again slow down the engine and release the

mechanism. Continue until the engine

accelerates evenly and without a time lag after

releasing the governor.

Loosen the packing

nut

before mak-

D

ing main fuel adjustment and then

tighten the

nut

to

a snug fit affer the adjustment has

been made. This procedure makes if easier

to

use the

carburetor adjusting fool and prevents fuel leaks

around the packing

nut.

Fuel leaks cause hard start-

ing because the float level becomes lower than

normal.

Cleaning and RepaicTo clean thecarburetor, soak all

components thoroughly in a good carburetorcleaner

following the cleaner manufacturer's instructions. Be

sure all carbon is cleaned from the carburetor bore,

especially in the area of the throttle valve. Blow out

the passages with compressed air. If possible, avoid

using wire to clean out the passages.

WARNING

Cleaning solutions fypically contain

I

strong chemicals fhaf may cause

injury if used improperly. Read all warning labels

before using.

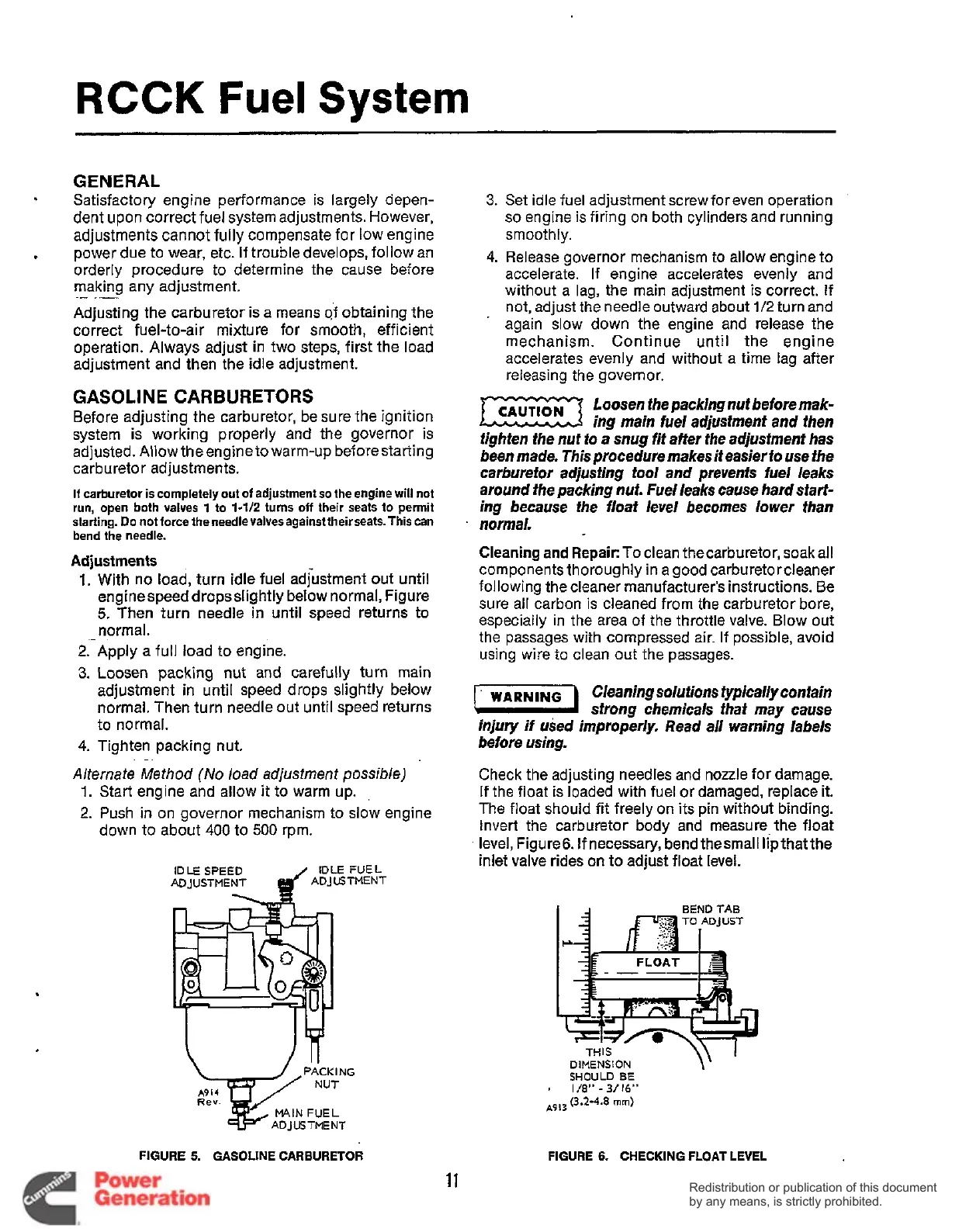

Check the adjusting needles and nozzle for damage.

If the float is loaded with fuel or damaged, replace

it.

The float should

fit

freely on its pin without binding.

Invert the carburetor body and measure the float

level, Figure6. If necessary, bend thesmall lipthatthe

inlet valve rides on to adjust float level.

DIMENSION

SHOULD

BE

I

I

/%"

-

3/

16"

A9,3

(3.2-4.8

mm)

FIGURE

5.

GASOLINE CARBURETOR

FIGURE

6.

CHECKING FLOAT LEVEL

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...