Engine

Disasse.mbly

If

engine disassembly is necessary, first remove all

the. complete assemblies (e.g. manifold with car-

buretor and vacuum speed booster). Individual

assemblies, as the carburetor, can be removed and

serviced later, if necessary. Follow the general dis-

assembly steps given below and refer to the ap-

propriate detailed instructions in this section. When

reassembling; check the text for special assembly

instructions.

Keep

alt

parts

in

their respective order

.

.

.

valve

assemblies,. rod caps for respective rod and piston

assemblies, etc. Analyze reasons for parts failures.

Use new gaskets for assembly.

GENERAL

DISASSEMBLY

1.

2.

3.

4.

5.

6.

7.

8.

9.

t

0.

11.

12.

1

3.

4

6.

Install crank gear aligning timing mark with mark

7.

Install valve assemblies and cylinder heads.

8.

Install gear cover and

oil

seal.

9.

Install flywheel.

10.

Install fuel pump, manifold assembly, air cleaner,

..

fuel lines, spark plug, breaker box, etc.

11.

Connect electrical wires, exhaust line and

battery.

12. Fill crankcase with proper oil.

on camshaft gear.

1

.

FLYWHEEL

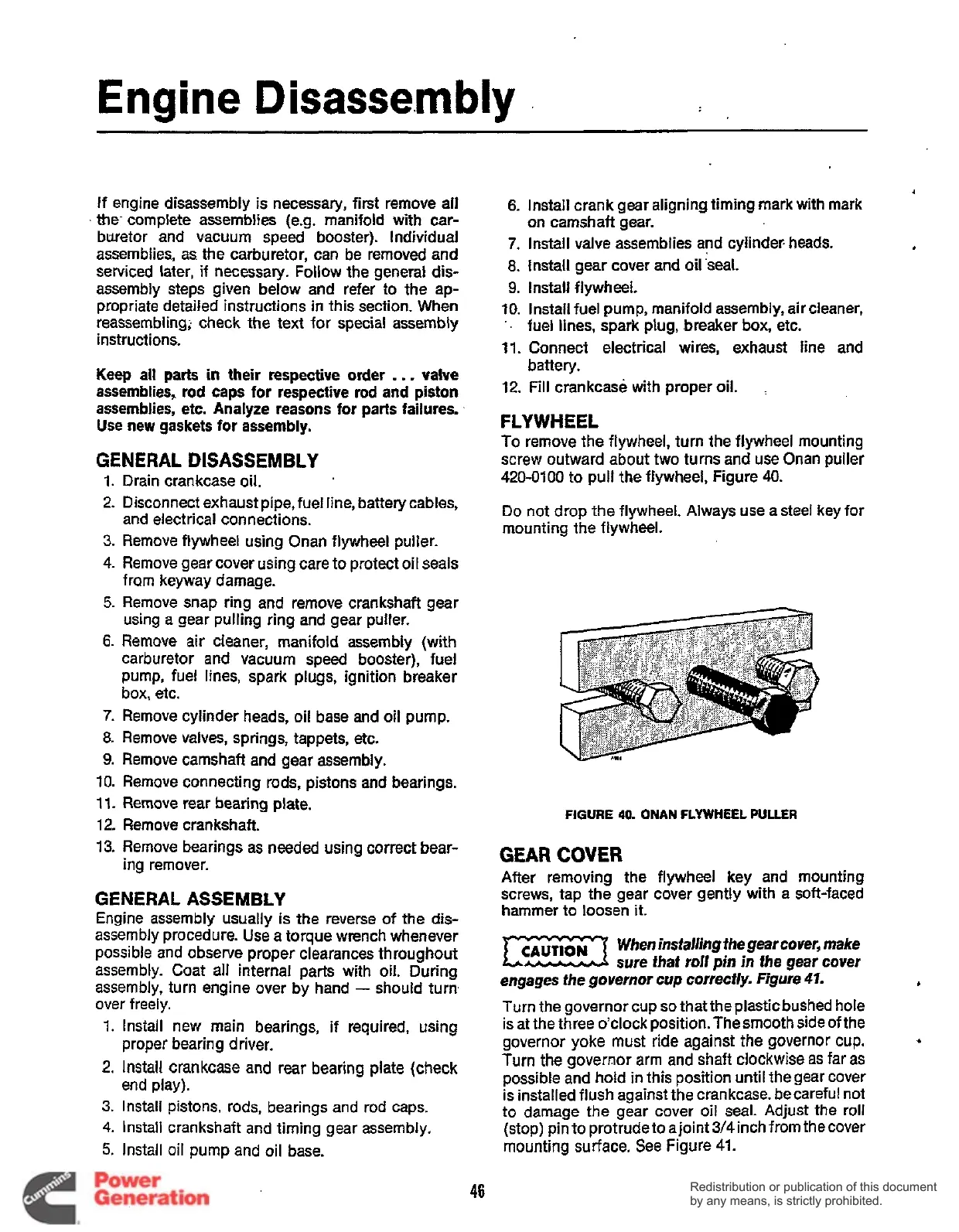

To

remove the flywheel, turn the flywheel mounting

screw outward about two turns and use Onan puller

~~

-

Drain crankcase oil.

420-0100 to pull the flywheel, Figure

40.

Disconnect exhaust

pipe7fuelline,

Do

not drop the flywheel. Always use astee1 key for

mounting the flywheel.

and electrical connections.

Remove flywheel using Onan flywheel puller.

Remove gear cover using care to protect oil seals

from keyway damage.

Remove snap ring and remove crankshaft gear

using

a

gear pulling ring and gear pulter.

Remove air cleaner, manifold assembly (with

carburetor and vacuum speed booster), fuel

pump, fuel lines, spark plugs, ignition breaker

box, etc.

Remove cylinder heads, oil base and oil pump.

Remove valves, springs, tappets, etc.

Remove camshaft and gear assembly.

Remove connecting rods, pistons and bearings.

Remove rear bearing plate.

Remove crankshaft.

FIGURE

40.

ONAN

FLYWHEEL

PULLER

Remove bearings as needed using correct bear-

ing remover.

GEAR

COVER

After removing the flywheel key and mounting

GENERAL

ASSEMBLY

Engine assembly usually is the reverse of the dis-

assembly procedure. Use a torque wrench whenever

possible and observe proper clearances throughout

assembly. Coat all internal parts with oil. During

assembly, turn engine over by hand

-

should turn

over freely.

1.

Install new main bearings, if required, using

2.

Install crankcase and rear bearing plate (check

3.

Install pistons, rods, bearings and rod caps.

4.

Install crankshaft and timing gear assembly.

5.

Install oil pump and oil base.

proper bearing driver.

end play).

screws, tap the gear cover gently with a soft-faced

hammer to loosen

it.

When

installing the gear cover, make

E3

sure

that

roll

pin

in

fhe

gear

cover

engages fhe governor

cup

correctly. Figure

41.

Turn the governor cup

so

that the plastic bushed hole

is at the three o’clock position. Thesmooth side of the

governor yoke must ride against the governor cup.

Turn the governor arm and shaft clockwise as far

as

possible and hold in this position until thegear cover

is installed flush against

the

crankcase. becareful not

to damage the gear cover oil seal. Adjust the roll

(stop) pin to protrude to ajoint

3/4

inch from the cover

mounting surface. See Figure

41.

b

.(

46

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...