CYLINDER

WALL

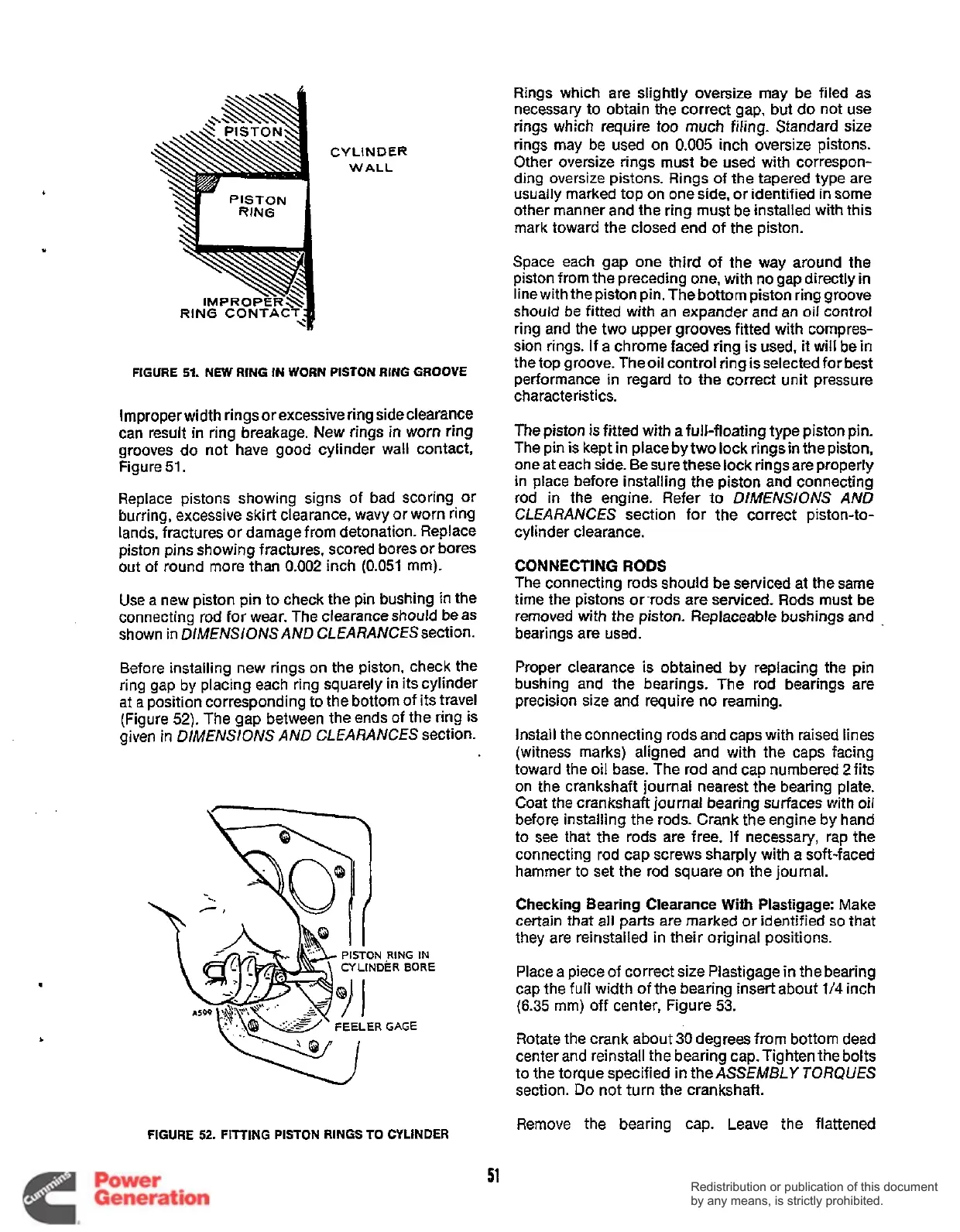

FIGURE

51.

NEW

RING

IN

WORN PISTON RING GROOVE

Improper width rings or excessive ring side clearance

can result

in

ring breakage. New rings

in

worn ring

grooves do not have good cylinder wall contact,

Figure

51.

Replace pistons showing signs

of

bad scoring or

burring, excessive skirt clearance, wavy or worn ring

lands, fractures or damage from detonation. Replace

piston pins showing fractures, scored bores or bores

out

of

round more than

0.002

inch

(0.051

mm).

Use a new piston pin to check the pin bushing in the

connecting rod for wear. The clearance should

be

as

shown in DIMENSIONS AND CLEARANCESsection.

Rings which are slightly oversize may be filed as

necessary to obtain the correct gap, but do not use

rings which require too much filing. Standard size

rings may be used on

0.005

inch oversize pistons.

Other oversize rings must be used with correspon-

ding

oversize pistons. Rings of the tapered type are

usually marked top

on

one side, or identified

in

some

other manner and the ring must be installed with this

mark toward the closed end of the piston.

Space each gap one third of the way around the

piston from the preceding one, with no gap directly

in

line with the piston pin. The bottom piston ring groove

should

be

fitted with an expander and an

oil

control

ring and the two upper grooves fitted with compres-

sion rings. If a chrome faced ring is used, it will be

in

the top groove. Theoil control ring is selected for best

performance in regard to the correct unit pressure

characteristics.

The piston

is

fitted with a full-floating type piston pin.

The pin is kept in place by two lock rings

in

the piston,

one at each side. Be sure these lock rings are properly

in place before installing the piston and connecting

rod

in

the engine. Refer to

DIMENSIONS

AND

CLEARANCES section for the correct piston-to-

cylinder clearance.

CONNECTING

RODS

The connecting rods should be serviced at the same

time the pistons orrods are serviced. Rods must be

removed

with

the piston. Replaceable bushings and

.

bearings are used.

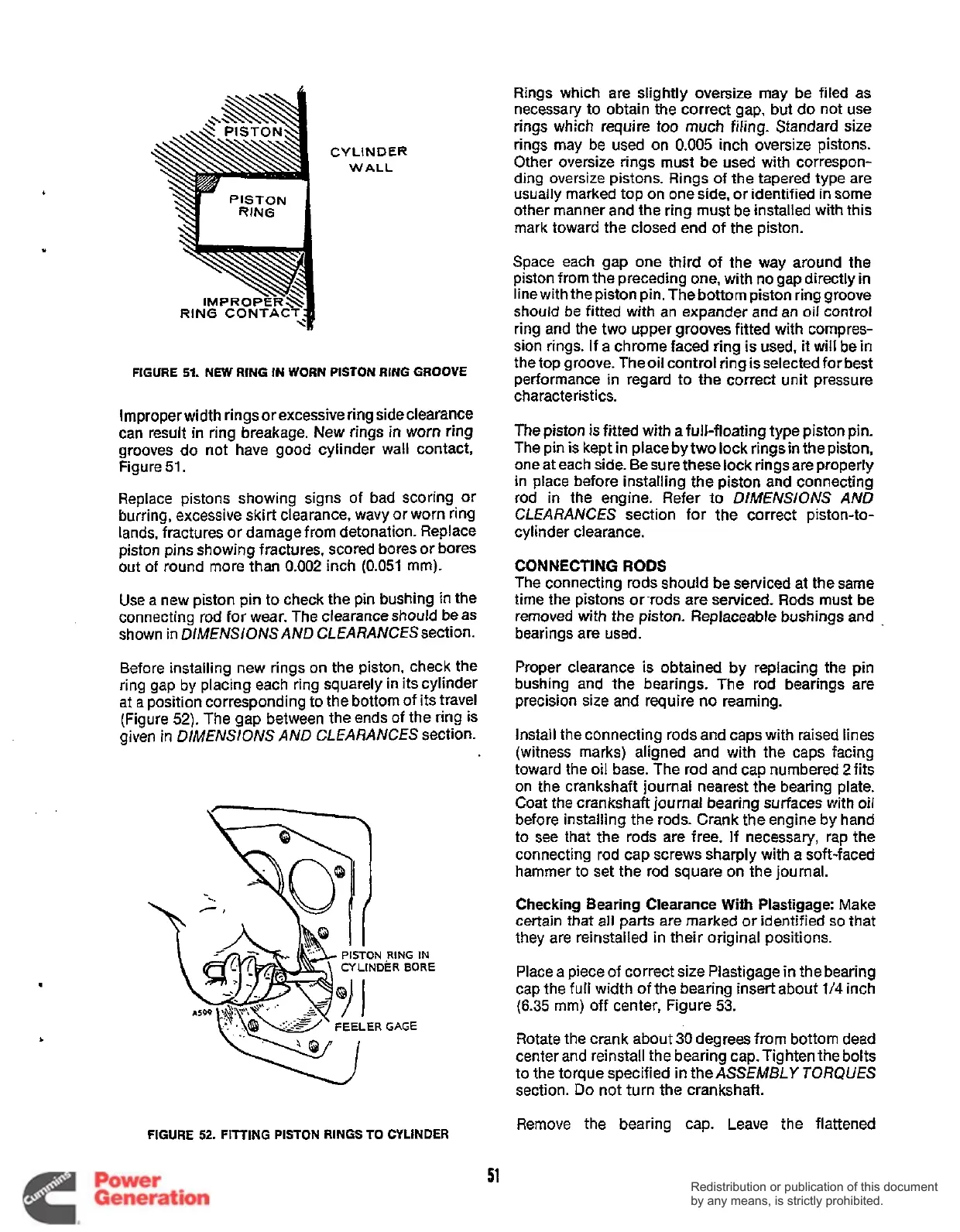

Before installing new rings on the piston, check the

ring gap

by

placing each ring squarely in its cylinder

at

a

position corresponding to the bottom of its travel

(Figure

52).

The gap between the ends of the ring is

given in DlMENSlONS AND CLEARANCES section.

.

Proper clearance is obtained by replacing the

pin

bushing and the bearings. The rod bearings are

precision size and require no reaming.

Install the connecting rods and caps with raised lines

(witness marks) aligned and with

the

caps facing

toward the oil base. The rod and cap numbered

2

fits

on the crankshaft journal nearest the bearing plate.

Coat the crankshaft journal bearing surfaces with oil

before installing the rods. Crank the engine by hand

to see that the rods are free. If necessary, rap the

connecting rod cap screws sharply with a soft-faced

hammer to set the rod square on the journal.

Checking Bearing Clearance

With

Plastigage: Make

certain that all parts are marked or identified

so

that

they are reinstalled in their original positions.

Place a piece of correct size Plastigage in the bearing

cap the full width

of

the bearing insert about

1/4

inch

(6.35

mm) off center, Figure

53.

Rotate the crank about

30

degrees from bottom dead

center and reinstall the bearing cap.Tighten the bolts

to the torque specified

in

the ASSEMBLY

TORQUES

section.

Do

not turn the crankshaft.

PISTON

.RING

IN

CY

LlNDER BORE

FEELERGAGE

FIGURE

52.

FITTING

PISTON

RINGS

TO

CYLINDER

Remove the bearing cap. Leave the flattened

51

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...