CY

Ll

NDER

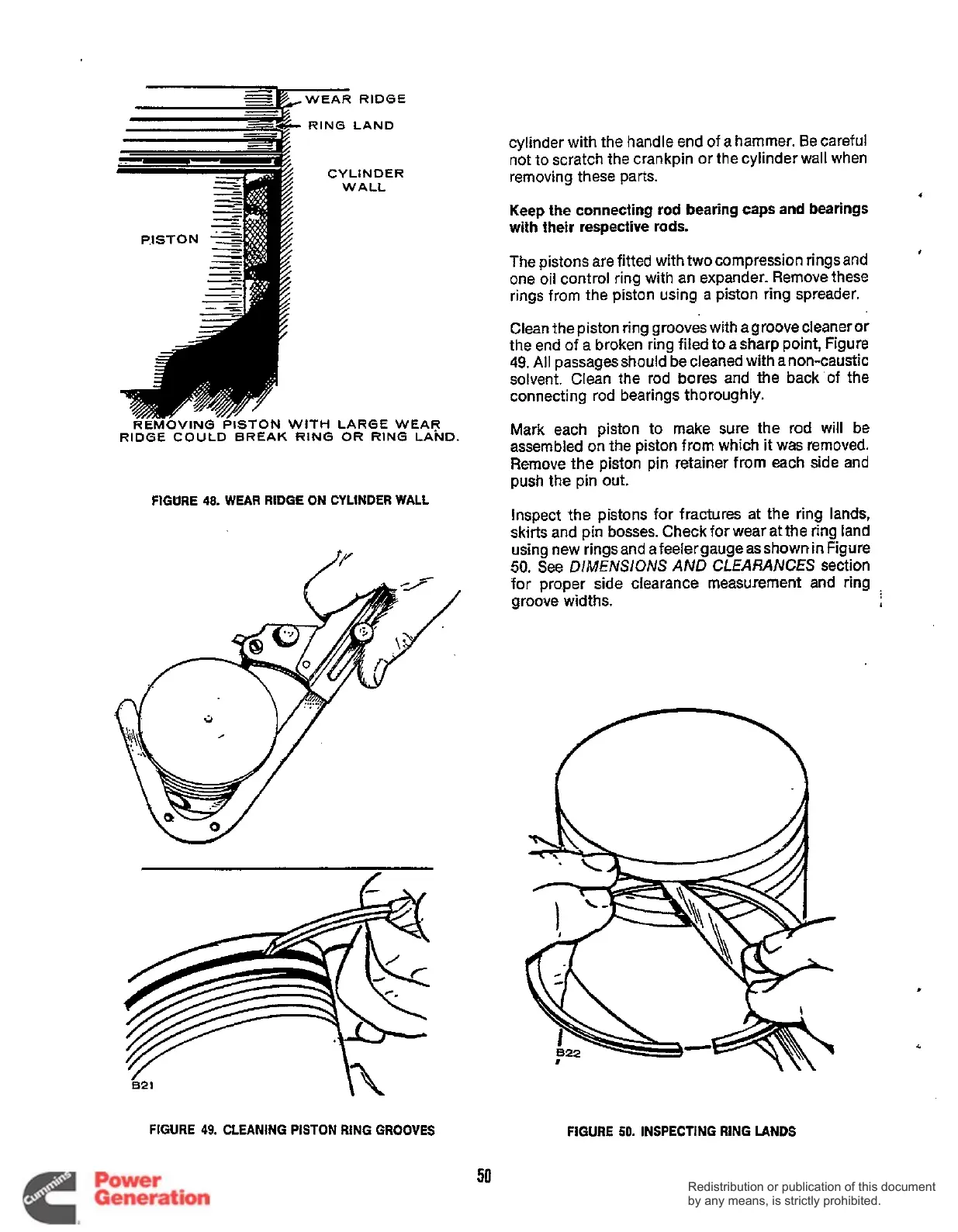

REMOVING PISTON

WITH

LARGE WEAR

RIDGE COULD BREAK RING

OR

RING LAND.

FIGURE

48.

WEAR RIDGE

ON

CYLINDER WALL

FIGURE

49.

CLEANING PISTON RING

GROOVES

cylinder with the handle end

of

a

hammer. Be careful

not to scratch the crankpin or

the

cylinder wall when

removing these parts.

Keep the connecting rod bearing caps and bearings

with their respective

rods.

The pistons

are

fitted with two compression rings and

one

oil

control ring with an expander. Remove these

rings from

the

piston using

a

piston ring spreader.

Clean

the

piston ring grooves with agroove cleaner or

the end

of

a

broken ring

filed

to asharp point, Figure

49.

All

passages should

be

cleaned with

a

non-caustic

solvent. Clean the rod bores and the

back

of

the

connecting rod bearings thoroughly.

Mark

each

piston to make sure the rod will

be

assembled on the piston from which it was removed.

Remove the piston pin retainer from each side and

push the pin out.

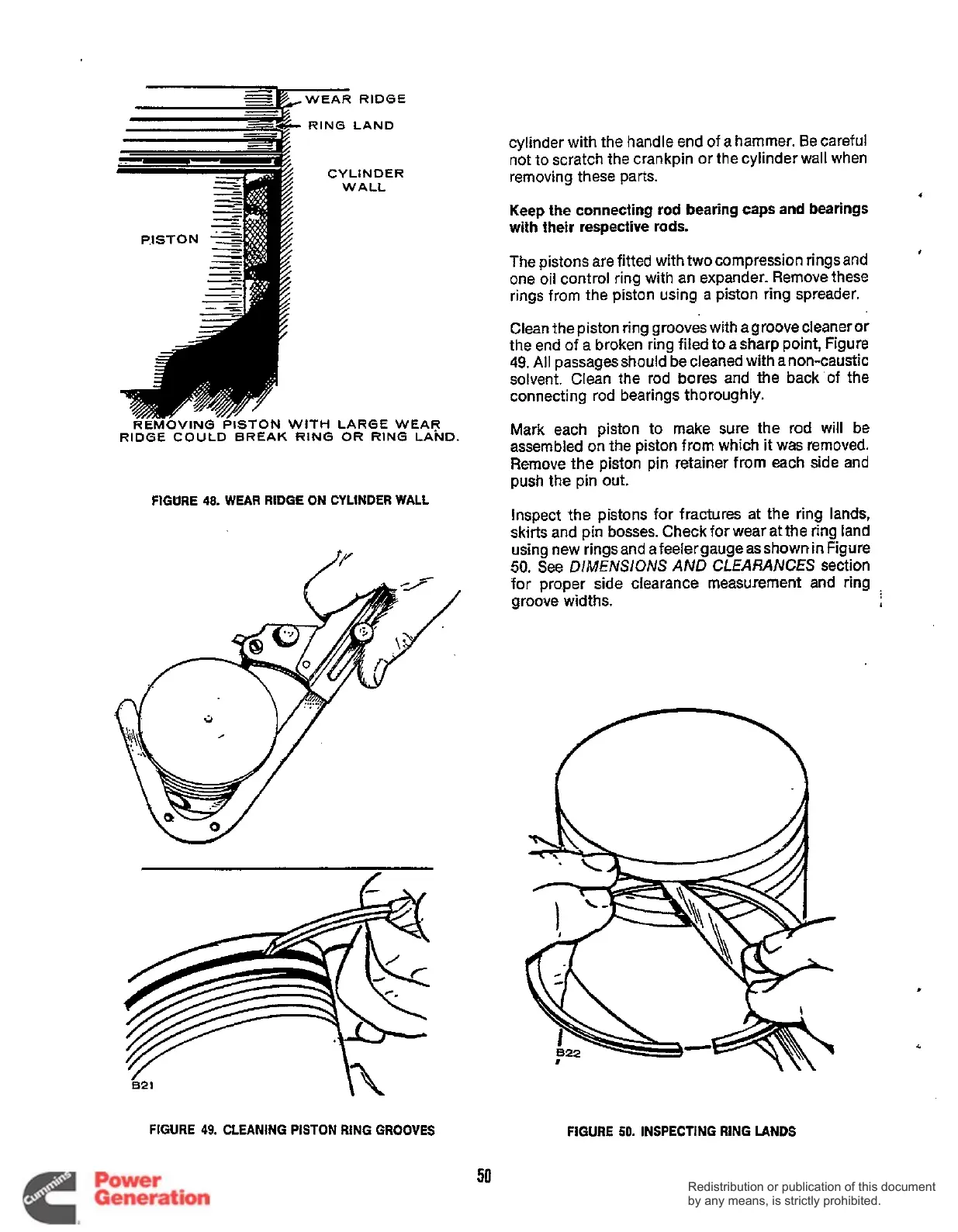

Inspect

the

pistons

for

fractures

at

the ring lands,

skirts and pin

bosses.

Check for wear at the ring land

using new rings and

a

feeler

gauge

as

shown in Figure

50.

See

DlAdENSlONS

AND

CLEARANCES

section

for

proper

side

clearance measurement and ring

.

groove widths.

1

4

#

FIGURE

50.

INSPECTING

RING

LANDS

50

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...