ELECTRIC STARTER INSPECTION AND

TROUBLESHOOTING

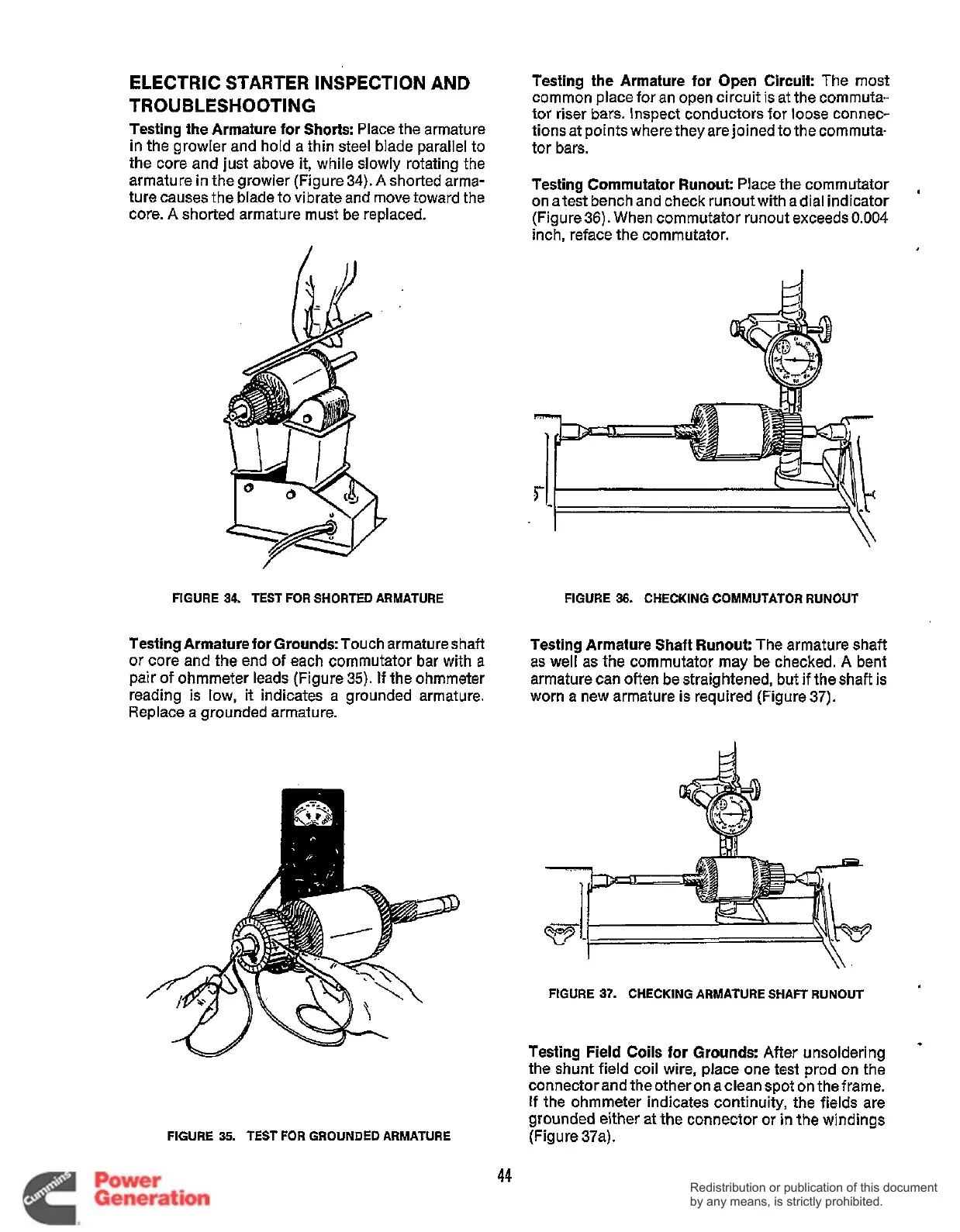

Testing the Armature for Shorts: Place the armature

in the growler and hold a thin steel blade parallel to

the core and just above

it,

while slowly rotating the

armature in the growler (Figure

34).

A

shorted arma-

ture causes the blade to vibrate and move toward the

core.

A

shorted armature must be replaced.

Testing the Armature for Open Circuit: The most

common place for an open circuit is at the commuta-

tor riser bars. inspect conductors for loose connec-

tions at points where they are joined to the commuta-

tor bars.

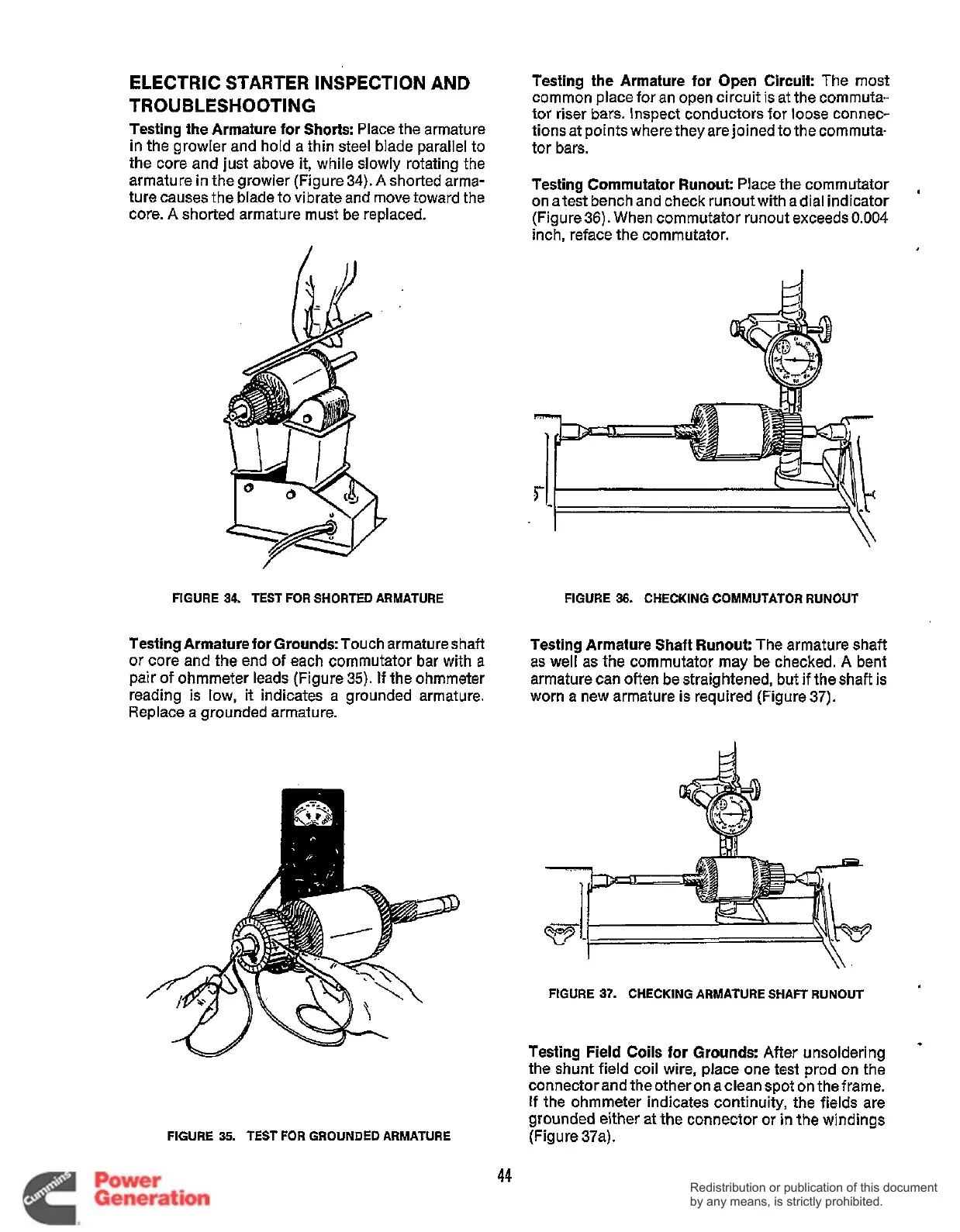

Testing Commutator Runout: Place the commutator

on a test bench and check runoutwith adial indicator

(Figure 36). When commutator runout exceeds

0.004

inch, reface the commutator.

,

d

FIGURE

34.

TEST FOR SHORTED ARMATURE FIGURE

36.

CHECKING COMMUTATOR RUNOUT

Testing Armature for Grounds: Touch armatureshaft

or core and the end of each commutator bar with

a

pair

of

ohmmeter leads (Figure 35). If the ohmmeter

reading is low,

it

indicates a grounded armature.

Replace a grounded armature.

Testing Armature Shaft Runout: The armature shaft

as well as the commutator may be checked.

A

bent

armature can often be straightened, but if the shaft is

worn a new armature is required (Figure

37).

FIGURE

35.

TEST

FOR GROUNDED ARMATURE

FIGURE

37.

CHECKING ARMATURE SHAFT RUNOUT

Testing Field Coils for Grounds: After unsoldering

the shunt field coil wire, place one test prod on the

connector and the other on a clean spot on the frame.

If

the ohmmeter indicates continuity, the fields are

grounded either at the connector or

in

the windings

(Figure 37a).

4

44

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...