When installing the gear cover oil seal, tap the seal

inward until it is

1-1/32

(26.2

mm) of an inch from the

mounting face

of

the cover.

t

L

When installing the bearing plate oil seal, tap the seal

into the bearing plate

bore

to bottom against the

shoulder in the plate bore. Use a seal expander.

or

place a piece

of

shim stock around the end of the

crankshaft when replacing the bearing plate to avoid

damaging the seal. Remove the shim stock as soon as

the plate

is

in place.

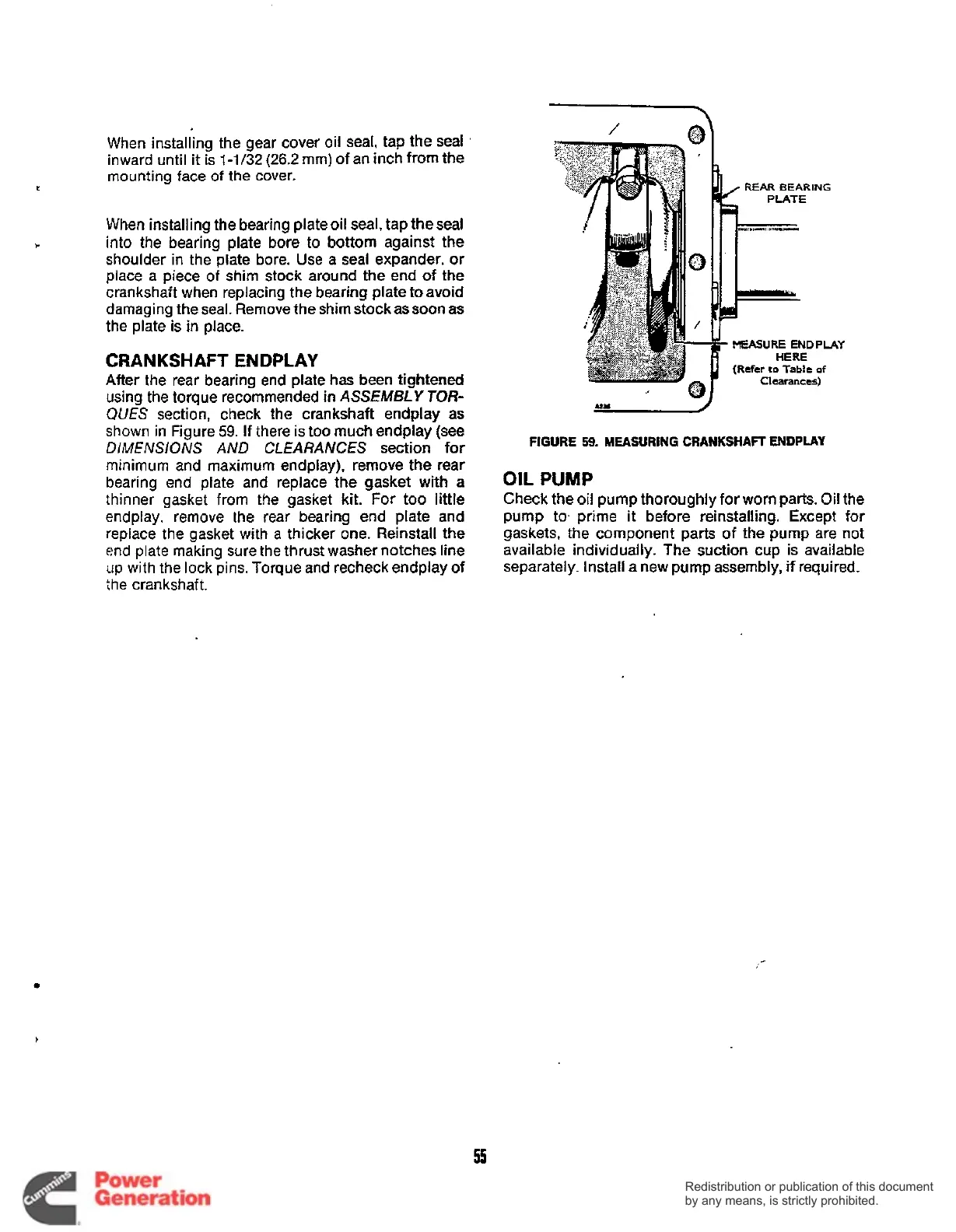

CRANKSHAFT

ENDPLAY

After the rear bearing end plate has been tightened

using the torque recommended

in

ASSEMBLY

TOR-

OIIES

section, check the crankshaft endplay as

shown in Figure

59.

If there

is

too much endplay (see

DIMENSIONS

AND

CLEARANCES

section

for

minimum and maximum endplay). remove the rear

bearing end plate and replace the gasket with a

thinner gasket from the gasket kit. For too little

endplay. remove the rear bearing end plate and

replace the gasket with

a

thicker one. Reinstall the

end plate making sure the thrust washer notches line

ap

with the lock pins. Torque and recheck endplay

of

the crankshaft.

WURE

ENDPLAY

(Refer

to

Table

of

Clearances)

FIGURE

59.

MEASURING

CRANKSHAFT

ENDPLAY

OIL

PUMP

Check the

oil

pump thoroughly for worn parts. Oil the

pump to. prime

it

before reinstalling. Except for

gaskets, the component parts of the pump are

not

available individually. The suction cup is available

separately. Install a new pump assembly, if required.

55

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...