MCCK

Cooling

System

DESCR

I

PTI

0

N

The MCCK cooling system is a pressure type system

which uses an engine mounted rubber impeller pump

to draw and circulate raw water throughout the

system.

In open type cooling systems, water enters the pump

located on the front right side of engine. The pump

delivers water to the cylinder jacket. Water flows

through the jacket and out openings in cylinder

heads controlled by thermostats.' For engine warm-

up, with thermostats closed, a by-pass from the

cylinder block to the thermostat allows water flow.

From thermostat, water passes through the water-

cooled exhaust manifold and out engine cooling

system.

MAINTENANCE

Cooling system maintenance includes periodic in-

spection for leaks, inspection of the rubber pump

impeller, and flushing and cleaning.

Confacf

wifh

hof

coolanf

mighf

result

n

in serious burns.

Do

not bleed

hot,

pressurized coolant from

a

closed cooling sysfem.

The rubber impeller, because of continuous flexing,

will, in time, need replacement. If impeller fails after

short service (usually under'500 hours), check for

possible defects, such as severe pitting or abrasion

caused by dirt in

the

cooling system.

Cooling system MUST be kept clean to function

properly. Scale reduces heat transfer and restricts

water flow. Flush system at least once a year and

more often if operation indicates clogged passages,

pump wear, or overheating.

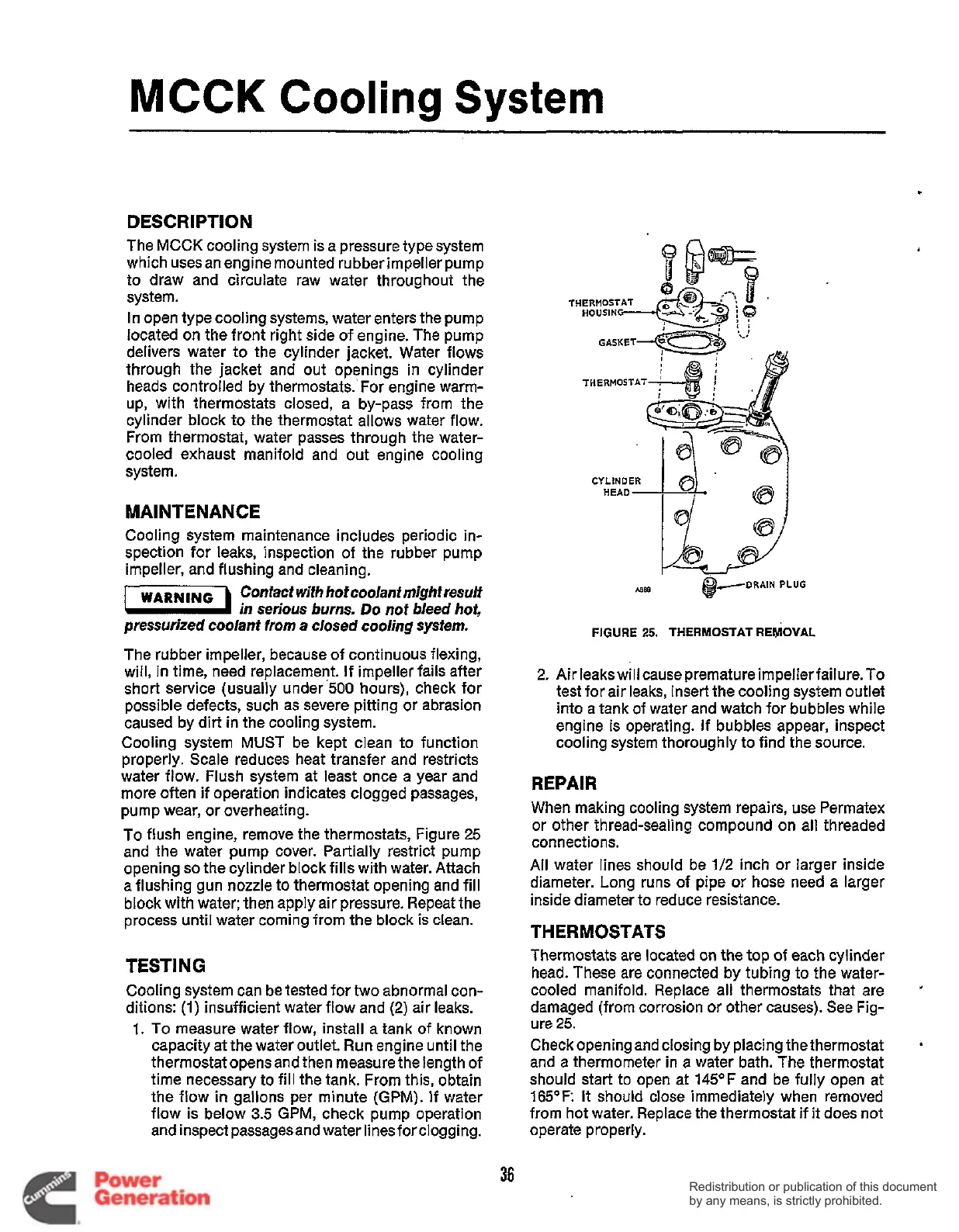

To flush engine, remove the thermostats, Figure

25

and the water pump cover. Partially restrict pump

opening

so

the cylinder block fills with water. Attach

a flushing gun nozzle to thermostat opening and fill

block with water; then apply air pressure. Repeat the

process until water coming from the block is clean.

WARNING

TESTING

Cooling system can be tested for two abnormal con-

ditions:

(1)

insufficient water flow and

(2)

air leaks.

1.

To

measure water flow, install a tank of known

capacity at the water outlet. Run engine until the

thermostat opens and then measure the length of

time necessary to fill the tank. From this, obtain

the flow

in

gallons per minute

(GPM).

If water

flow is below

3.5

GPM, check pump operation

and inspect passages and water linesforclogging.

THERMOSTAT

As888

@-DRAIN

PLUG

FIGURE

25.

THERMOSTAT

REMOVAL

2.

Air leaks will cause premature impeller failure.To

test for air leaks, insert the cooling system outlet

into a tank of water and watch for bubbles while

engine is operating. If bubbles appear, inspect

cooling system thoroughly to find the source.

REPAIR

When making cooling system repairs, use Permatex

or other thread-sealing compound on all threaded

connections.

All

water lines should be

1/2

inch or larger inside

diameter. Long runs of pipe or hose need a larger

inside diameter to reduce resistance.

THERMOSTATS

Thermostats are located on the

top

of each cylinder

head. These are connected by tubing to the water-

cooled manifold. Replace all thermostats that are

damaged (from corrosion or other causes). See Fig-

ure

25.

Check opening and closing by placing thethermostat

and a thermometer in a water bath. The thermostat

should start

to

open at

145OF

and be fully open at

165OF:

It should close immediately when removed

from hot water. Replace the thermostat if

it

does not

operate properly.

"

.

36

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...