FUEL

PUMP

TEST

PUMP

ASSEMBLY

I

Test the fuel pump by checking the pump outlet pres-

sure. Use the following procedure.

1.

Remove the fuel line from the pump outlet and

install a pressure gauge.

2. Press the START switch and hold it for several

seconds until pressure reading is constant.

3. Pressure reading should be 2-112 to 3-1/4 psi

(17.2 to 22.4 kPa). If the retension is good,

the

pressure should stay constant or drop

off

very

slowly.

A

low pressure reading with little or no pressure drop

indicates a weak or broken diaphragm or diaphragm

spring, worn linkage or leaky check valves. If pres-

sure is above maximum, the pump diaphragm

is

too

tight or the diaphragm (or plunger) return spring

is

too strong. Any of the above conditions are cause for

repair or replacement

of

the pump.

ELECTRIC FUEL

PUMP

The Facet and Bendix pumps incorporate a hollow

stainless steel plunger in a brass cylinder. The plunger

has no gland or seal, but is freely fitted. The fluid

being pumped provides the seal by filling the small

clearance between the plunger and cylinder. Energiz-

ing the pump's electric solenoid pulls the plunger

downward, compressing the return spring. When the

solenoid is de-energized, the return spring drives the

plunger back, delivering fuel to the pump outlet.

DO

not substitute automotive type

electric fuel pumps for sfandard

Onan supplied electric pumps. The output pressure

is much higher and can cause carburetor flooding or

fuel leakage, creating a fire hazard.

Fuel

Pump

Repair

Service of the Facet pump is limited to the bottom

cover, filter, plunger tube, and plunger assembly.

All

parts

of

the electric system are hermetically sealed

in

a gas atmosphere and are not serviceable. If electrical

failure occurs, replace the pump.

Do not tamper with the seal at the

Lzz2

center of the mounting bracket on

the side of the pump as it retains the dry gas which

surrounds the electrical system. Electrical system

components are not serviceable.

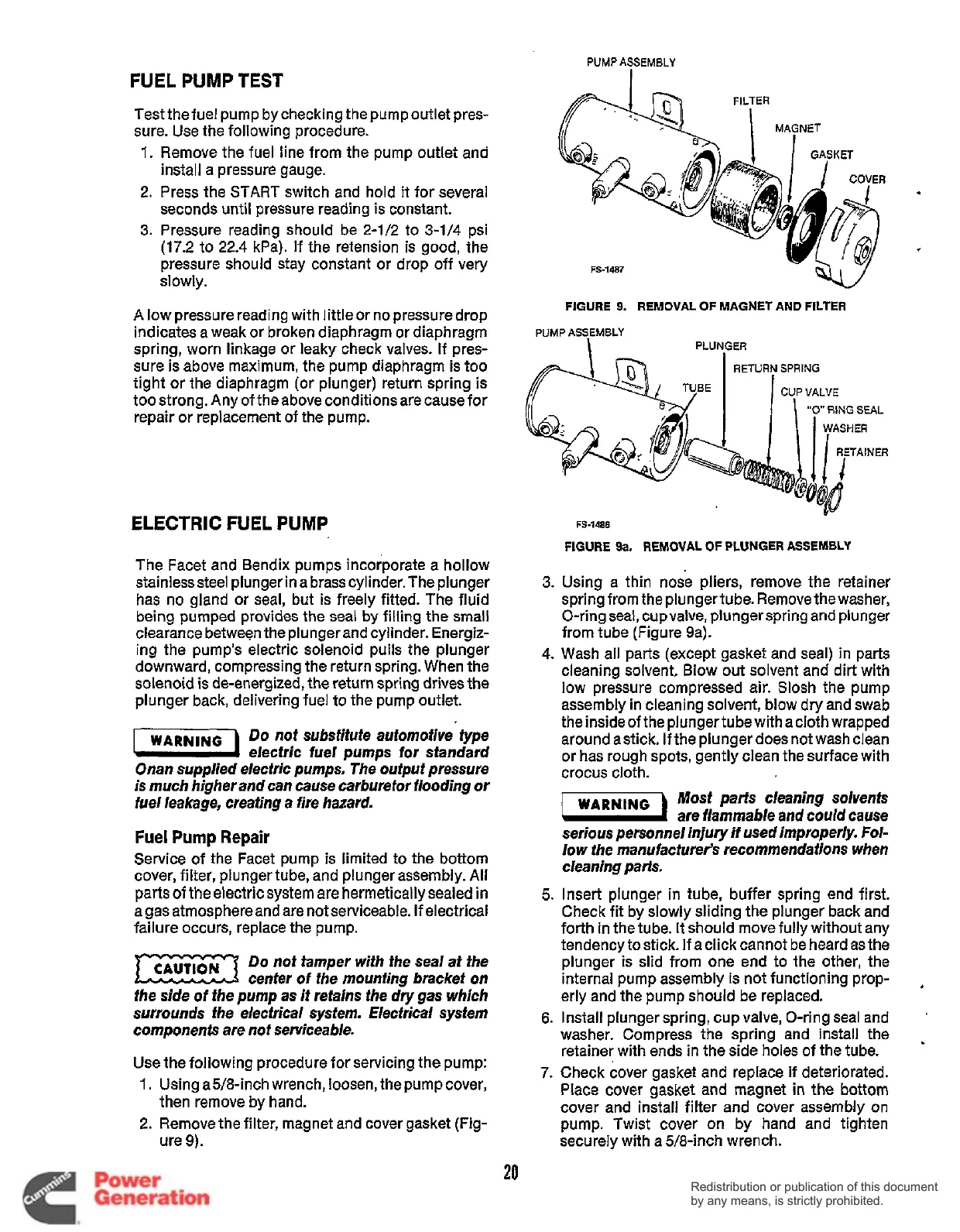

Use the following procedure for servicing the pump:

1.

Using a5/8-inch wrench, loosen, the pump cover,

2.

Remove

the

filter, magnet and cover gasket (Fig-

then remove by hand.

ure 9).

81

a]

1

1

GASKET

%

1

COVER

FS-1487

FIGURE

9.

REMOVAL

OF

MAGNET AND

FILTER

PUMP

ASSEMBLY

PLUNGER

"0"

RING

SEAL

WASHER

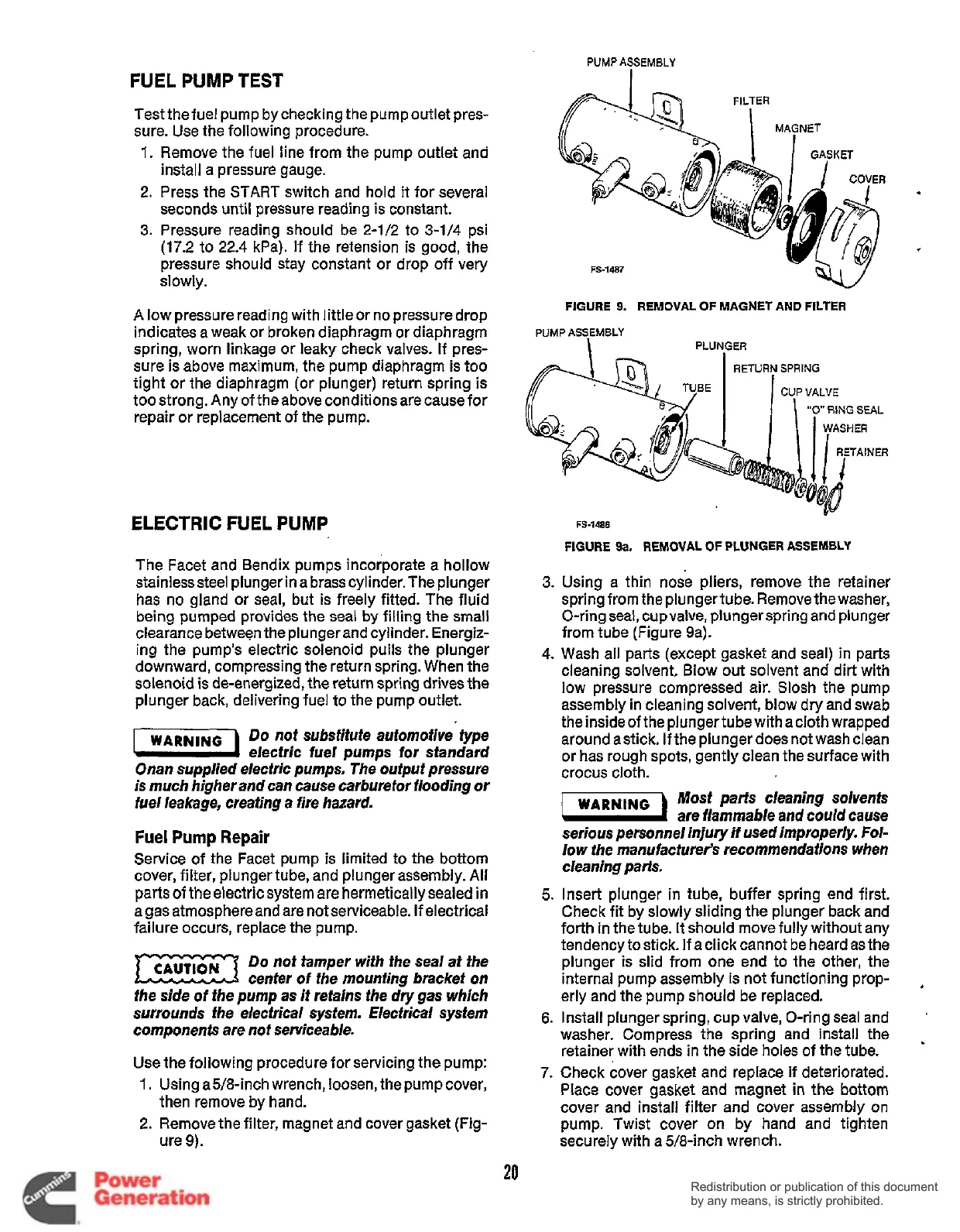

3.

4.

5.

6.

7.

FS-1486

FIGURE

9a.

REMOVAL

OF

PLUNGER ASSEMBLY

Using a thin nose pliers, remove the retainer

spring from the plungertube. Removethewasher,

O-ring seal, cup valve, plunger spring and plunger

from tube (Figure sa).

Wash all parts (except gasket and seal) in parts

cleaning solvent, Blow out solvent and dirt with

low pressure compressed air. Slosh the pump

assembly in cleaning solvent, blow dry and swab

the inside of the plungertube with a cloth wrapped

around astick. If the plunger does not wash clean

or has rough spots, gently clean the surface with

crocus cloth.

Most parts cleaning solvents

are flammable

and

could cause

serious personnel injury if used improperly. Fol-

low the manufacturer's recommendations when

cleaning parts.

Insert plunger in tube, buffer spring end first.

Check fit by slowly sliding the plunger back and

forth in the tube.

It

should move fully without any

tendency tostick. If aclick cannot be heard as the

plunger

is

slid from one end

to

the other, the

internal pump assembly is not functioning prop-

erly and the pump should be replaced.

Install plunger spring, cup valve, O-ring seal and

washer. Compress the spring and install the

retainer with ends in the side holes of the tube.

Check cover gasket and replace if deteriorated.

Place cover gasket and magnet in the bottom

cover and install filter and cover assembly on

pump. Twist cover on by hand and tighten

securely with a 5/8-inch wrench.

20

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...