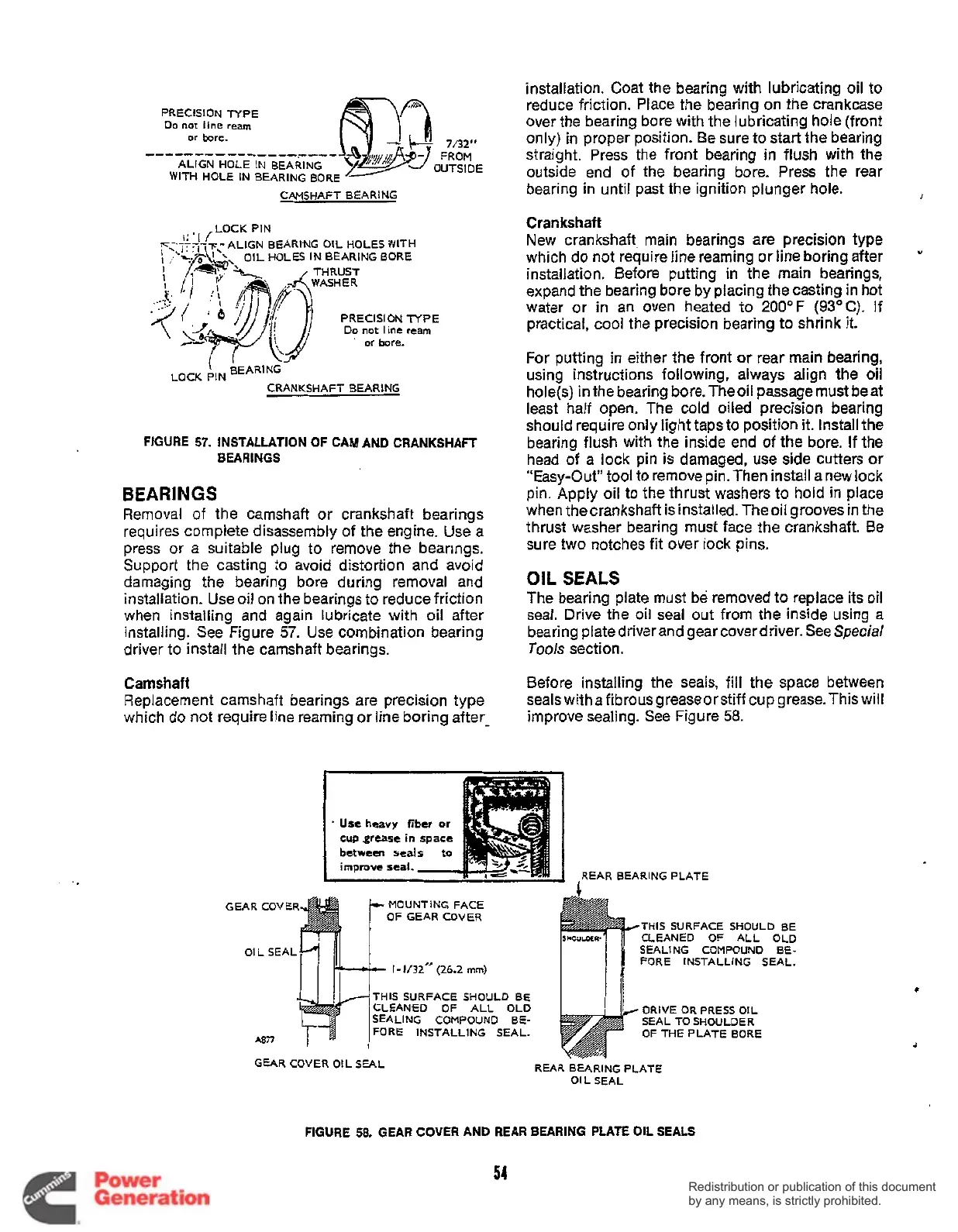

PRECISION TYPE

Do

not

line ream

or

bore.

------

----

-----.----

ALIGN HOLE IN BEARING

WITH HOLE IN BEARING BORE

CAMSHAFT BEARING

.

OIL

HOLES

IN BEARING BORE

1

BEARING

LOCK PIN

CRANKSHAFT BEARING

FIGURE

57.

INSTALLATION OF CAM AND CRANKSHAFT

BEARINGS

BEARINGS

Removal of the camshaft or crankshaft bearings

requires complete disassembly of the engine. Use a

press or a suitable plug to remove the bearings.

Support the casting to avoid distortion and avoid

damaging the bearing bore during removal and

installation. Use oil on the bearings to reduce friction

when installing and again lubricate with oil after

installing. See Figure

57.

Use combination bearing

driver to install the camshaft bearings.

Camshaft

Replacement camshaft bearings are precision type

which do not require line reaming or line boring after-

installation. Coat the bearing with lubricating oil to

reduce friction. Place the bearing on the crankcase

over the bearing bore with the lubricating hole (front

only) in proper position. Be sure to start the bearing

straight. Press the front bearing in flush with the

outside end of the bearing bore. Press the rear

bearing in until past the ignition plunger hole.

Crankshaft

New crankshaft, main bearings are precision type

which do not require line reaming or line boring after

installation. Before putting in the main bearings,

expand the bearing bore by placing the casting in hot

water or in an oven heated to 2OOOF

(93OC).

If

practical, cool the precision bearing to shrink it.

For putting in either the front or rear main bearing,

using instructions following, always align the oil

hole(s) in the bearing bore. Theoil passage must beat

least half open. The cold oiled precision bearing

should require only light taps to position it. Install the

bearing flush with the inside end of the bore.

If

the

head of a lock pin

is

damaged, use side cutters

or

"Easy-Out'' tool to remove pin. Then install a new lock

pin. Apply oil to the thrust washers to hold in place

when

thecrankshaftisinstalled.Theoi1groovesin

the

thrust washer bearing must face the crankshaft. Be

sure two notches fit over lock pins.

I

"

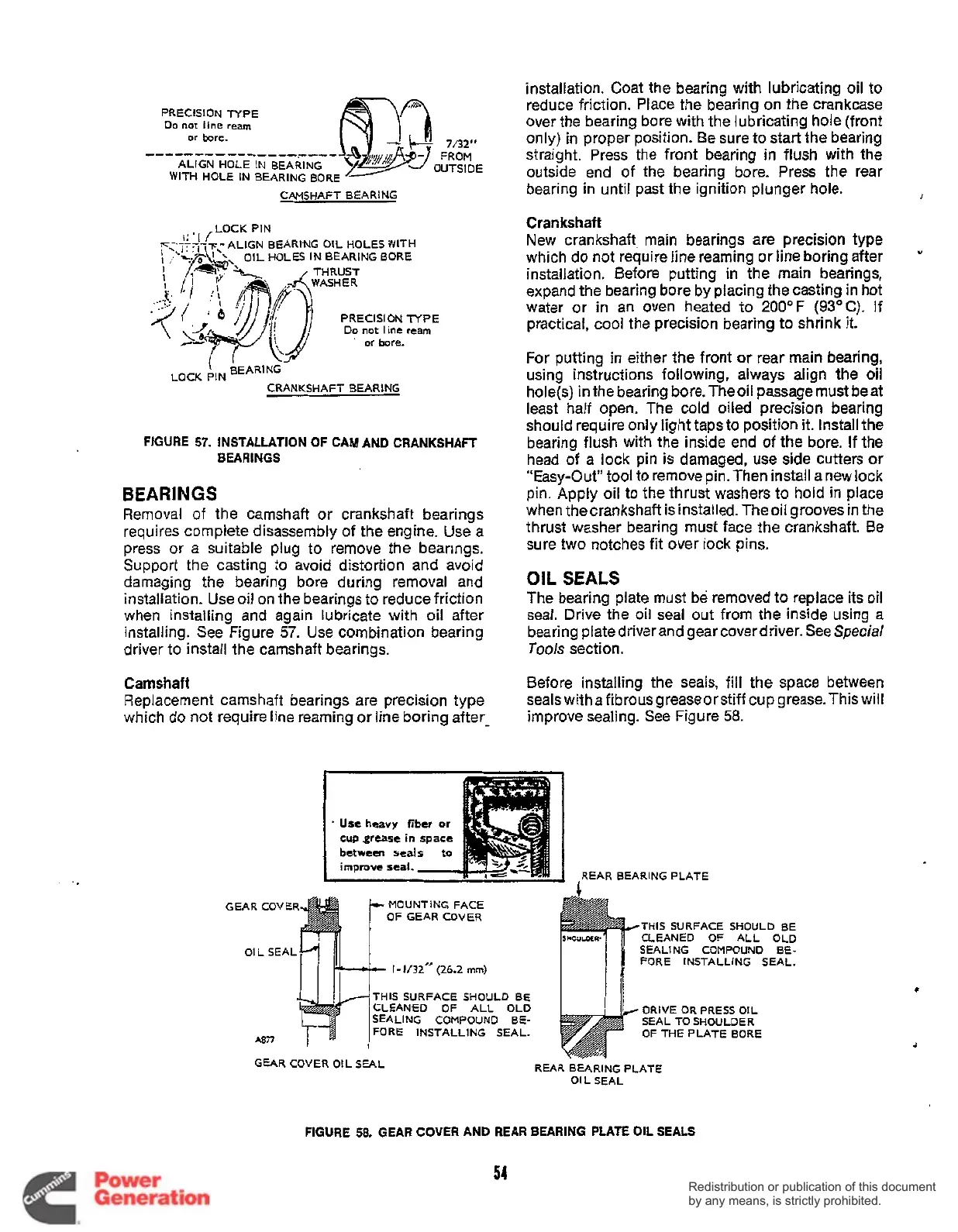

OIL

SEALS

The bearing plate must be removed to replace its oil

seal. Drive the oil seal out from the inside using a

bearing plate driver and gear cover driver. See

Special

Tools

section.

Before installing the seals, fill the space between

sealswith afibrousgreaseorstiff cup grease.Thiswil1

improve sealing. See Figure

58.

.

Use heavy fiber

or

cup .grease

in

between seal

improve seal.

MOUNTING FACE

OF GEAR COVER

GEAR COVER

OIL

SEAL^

/4

I-

1/32''

(26.2

mrn)

THIS SURFACE SHOULD BE

CLEANfD OF ALL OLD

SEALING COMPOUND BE-

FORE INSTALLING SEAL.

A877

1

REAR BEARING PLATE

THIS SURFACE SHOULD BE

CLEANED OF ALL OLD

SEALING COMPOUND BE-

FORE INSTALLING SEAL.

DRIVE

OR PRESS OIL

SEAL TO SHOULDER

OFTHEPLATEBORE

GEAR COVER O!L SEAL

REAR BEARING PLATE

OIL SEAL

FIGURE

58.

GEAR

COVER

AND REAR BEARING PLATE OIL SEALS

54

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...