Thus,

1800

rprn gives a

60

hertz frequency, and

1500

rprn gives

50

hertz frequency.

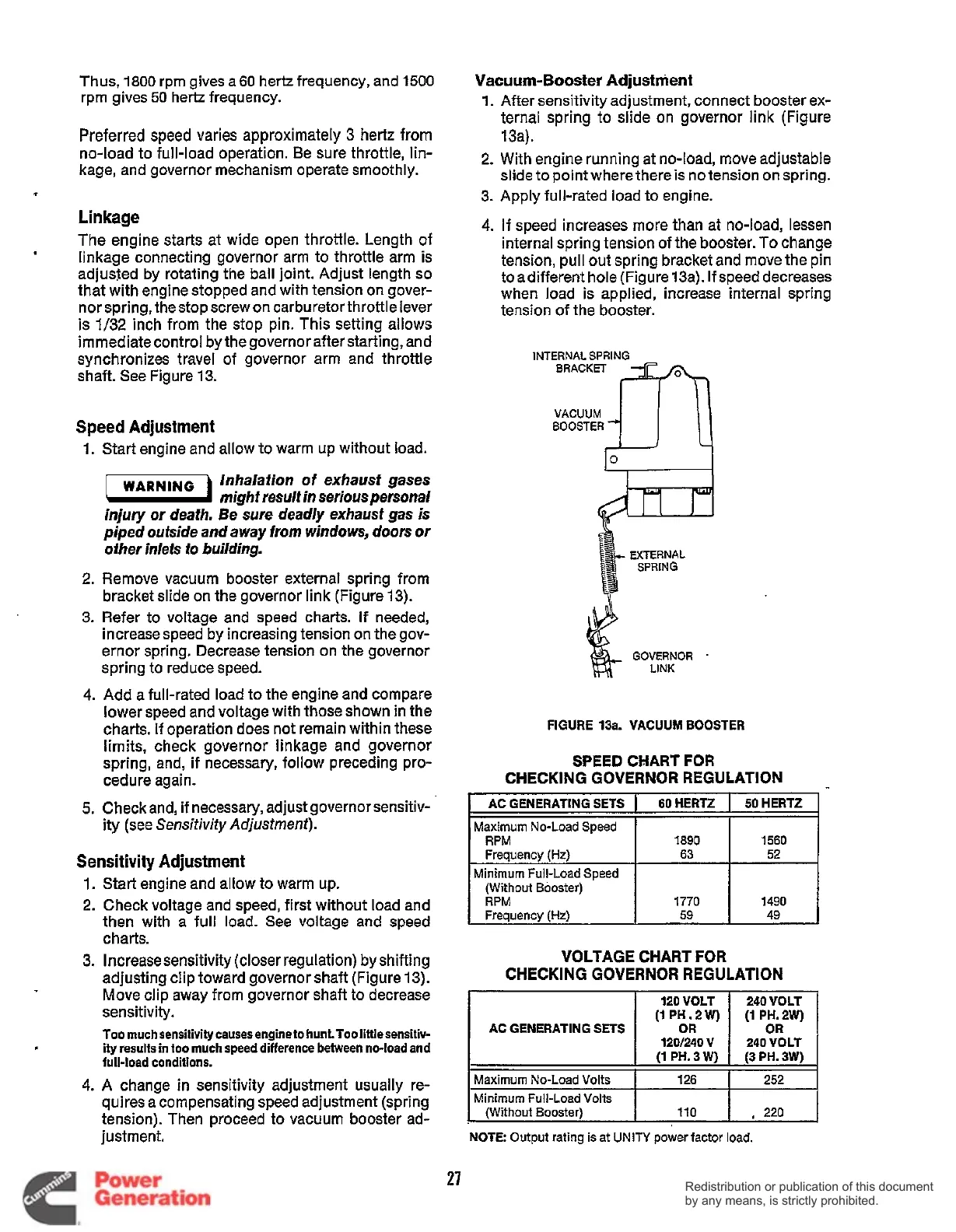

AC GENERATING SETS

Maximum No-Load Speed

RPM

Preferred speed varies approximately

3

hertz from

no-load to full-load operation. Be sure throttle, lin-

kage, and governor mechanism operate smoothly.

60

HERTZ

50

HERTZ

1890

1560

Linkage

The engine starts at wide open throttle. Length of

linkage connecting governor arm to throttle arm is

adjusted by rotating the ball joint. Adjust length

so

that with engine stopped and with tension on gover-

nor spring, the stop screw on carburetor throttle lever

is 1/32 inch from the stop pin. This setting allows

immediate control by the governor after starting, and

synchronizes travel of governor arm and throttle

shaft. See Figure 13.

*

(Without Booster)

RPM

Frequency

(Hz)

Speed Adjustment

1770

1490

59

49

1.

2.

3.

4.

5.

AC GENERATING

SETS

Maximum No-Load Volts

Minimum Full-Load

Volts

(Without Booster)

Start engine and allow to warm up without load.

WARNING

Inhalation

of

exhaust gases

n

might result in serious personal

injury

or

death. Be sure deadly exhaust gas is

piped outside and away from windows,

doors

or

other inlefs to building.

Remove vacuum booster external spring from

bracket slide on the governor link (Figure 13).

Refer to voltage and speed charts. If needed,

increase speed by increasing tension on the gov-

ernor spring. Decrease tension on the governor

spring to reduce speed.

Add a full-rated load to the engine and compare

lower speed and voltage with those shown in the

charts. If operation does not remain within these

limits, check governor linkage and governor

spring, and, if necessary, follow preceding pro-

cedure again.

Check and, if necessary, adjust governor sensitiv-

ity (see

Sensitivity

Adjustment).

120 VOLT

240

VOLT

(1

PH.

2W)

OR

OR

1201240 V

240

VOLT

(1

PH.

3

W)

(3

PH.

3W)

(1 PH .2

W)

126

252

110

,

220

Sensitivity Adjustment

1.

Start engine and allow to warm up.

2.

Check voltage and speed, first without load and

then with a full load. See voltage and speed

charts.

3.

Increasesensitivity (closer regulation) by shifting

adjusting clip toward governor shaft (Figure 13).

Move clip away from governor shaft to decrease

sensitivity.

Too

much sensitivity causes engine

to

hunt.Toolittlesensitiv-

ity

results in

too

much speed difference between no-load and

full-load conditions.

4.

A change in sensitivity adjustment usually re-

quires a compensating speed adjustment (spring

tension). Then proceed to vacuum booster ad-

justment.

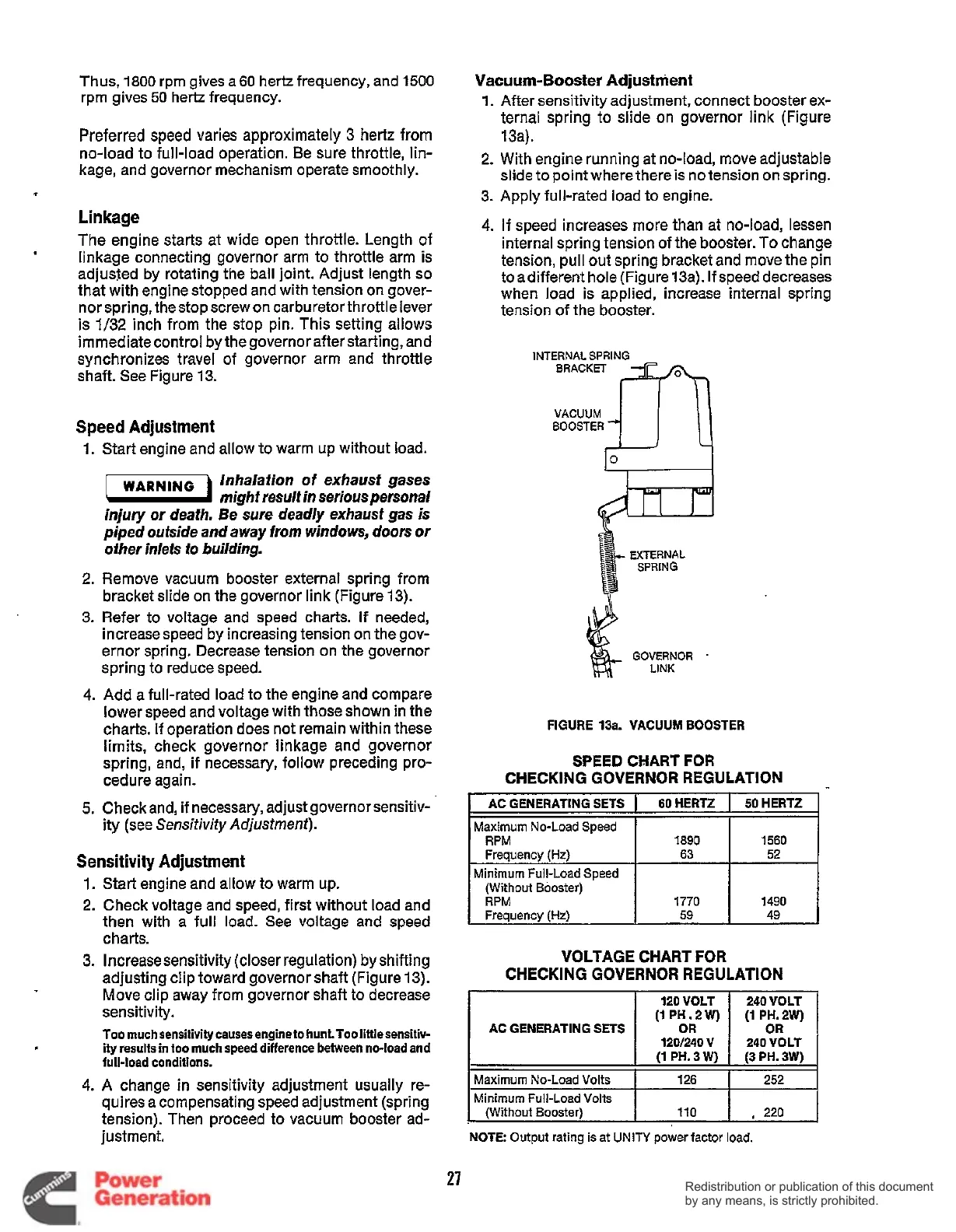

Vacuum-Booster

Adjustment

1.

After sensitivity adjustment, connect booster ex-

ternal spring to slide on governor link (Figure

13a).

2.

With engine running at no-load, move adjustable

slide to point where there

is

no tension on spring.

3. Apply full-rated load to engine.

4.

If

speed increases more than at no-load, lessen

internal spring tension of the booster. To change

tension, pull out spring bracket and move the pin

toadifferent hole (Figure 13a). If speed decreases

when load is applied, increase internal spring

tension of the booster.

VACUUM

BOOSTER

EXTERNAL

SPRING

FIGURE 13a. VACUUM BOOSTER

SPEED

CHART FOR

CHECKING GOVERNOR REGULATION

Frequency

(Hz)

I

63

I

52

Minimum Full-Load

Speed

I

VOLTAGE CHART FOR

CHECKING GOVERNOR REGULATION

27

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...