Repair:

If choke will not heat properly, check for

broken heater wire, high-resistance connections, or

broken lead wires to the bi-metal and heater assem-

bly. With the element at room temperature, check the

heater resistance with an ohmmeter. The resistance

should be about 30.6 to 37.4 ohms for a 12 volt sys-

tem. If the heater is defective, replace

it

with a new

one. When the start button is engaged, the solenoid

should cause the spring-loaded armature to contact

the solenoid core.

If this does not occur, check for broken lead wiresora

defective solenoid coil. There must be slack in the

lead wires between the choke body and the bi-metal

'

and heater assembly. The solenoid coil resistance

should be 2.09 to 2.31 ohms in a 12 volt system.

When replacing the cover on the thermostat and

heater assembly, be certain that the choke heater

lead wires have been correctly installed in the choke

housing. Improper replacement of the lead wires can

cause the choke assembly to malfunction.

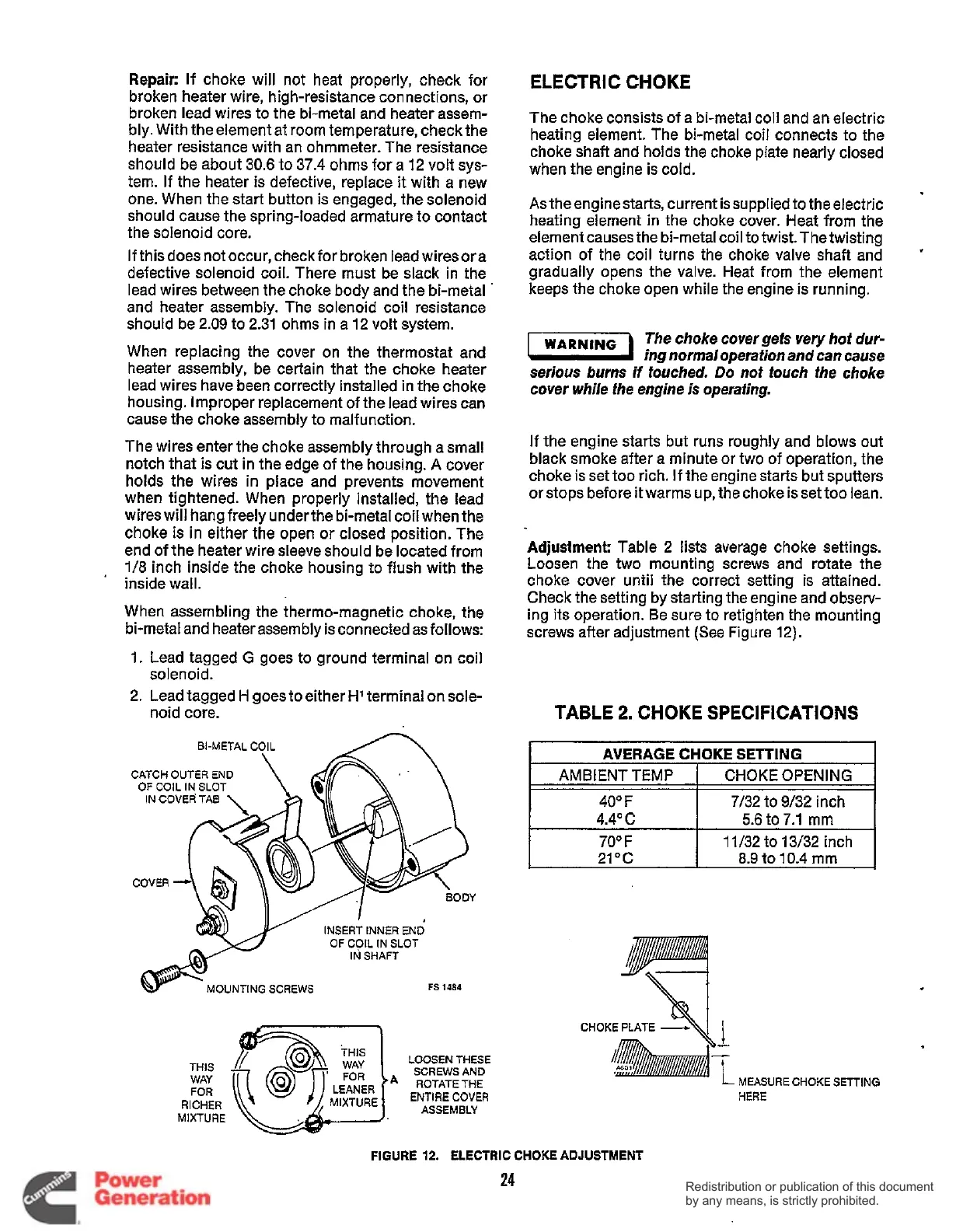

The wires enter the choke assembly through a small

notch that is cut in the edge

of

the housing.

A

cover

holds the wires in place and prevents movement

when tightened. When properly installed, the lead

wires will hang freely underthe bi-metal coil when the

choke is in either the open or closed position. The

end of the heater wire sleeve should be located from

1/8

inch inside the choke housing to flush with

the

When assembling the thermomagnetic choke, the

bi-metal and heater assembly is connected as follows:

1. Lead tagged

G

goes to ground terminal on coil

2. Lead tagged

H

goes to either

H1

terminal on sole-

'

inside wall.

solenoid

.

noid core.

CATCH

OUTER

END

OF

COIL

IN

SLOT

IN

COVER

TAB

COVER

INSERT

INNER

END

OF

COIL

IN SLOT

IN

SHAFT

MOUNTING

SCREWS

FS

1484

THIS

WAY

FOR

RICHER

MIXTURE

'

FOR

A

LEANER

MIXTURE

i

LOOSEN

THESE

SCREWS

AND

ROTATE

THE

ENTIRE

COVER

ASSEMBLY

ELECTRIC CHOKE

The choke consists

of

a bi-metal coil and an electric

heating element. The bi-metal coil connects to the

choke shaft and holds the choke plate nearly closed

when the engine is cold.

As theenginestarts, current is supplied to the electric

heating element in the choke cover. Heat from the

element causes the bi-metal coil to twist. The twisting

action of the coil turns the choke valve shaft and

gradually opens the valve. Heat from the element

keeps the choke open while the engine is running.

'

WARNlNG

The choke cover gets very hot

dur-

-

ing normal operation and can cause

serious burns

if

touched.

Do

not touch the choke

cover while the engine

is

operating.

If

the engine starts but runs roughly and blows out

black smoke after a minute or two of operation, the

choke is set too rich. If the engine starts but sputters

or stops before it warms up, the choke is set too lean.

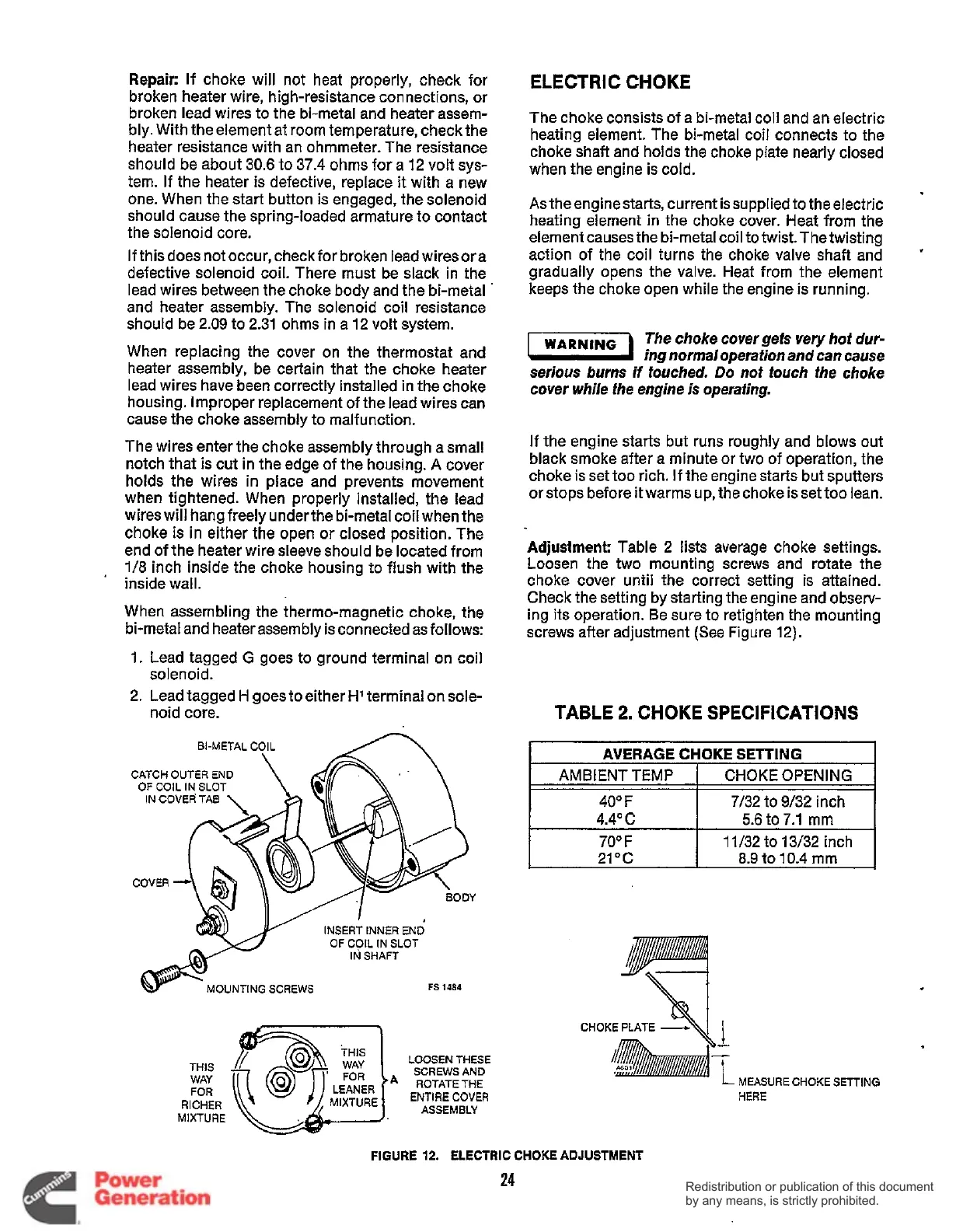

Adjustment:

Table 2 lists average choke settings.

Loosen the two mounting screws and rotate the

choke cover until the correct setting is attained.

Check the setting by starting the engine and observ-

ing its operation. Be sure to retighten the mounting

screws after adjustment

(See

Figure 12).

TABLE

2.

CHOKE SPECIFICATIONS

L

AVERAGE

CHOKE

SETTING

I

AMBIENT TEMP

I

CHOKE OPENING

I

40"

F

I

7/32 to 9/32 inch

4.4O

c

5.6 to

7.1

rnm

I

70'

F

I

11/32 to 13/32 inch

I

21°C

8.9

to 10.4 mm

CHOKE

PLATE

L

MEASURE

HERE

CHOKE

SETTING

FIGURE

12.

ELECTRIC CHOKE ADJUSTMENT

24

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...