If this does not occur, checkfor broken lead wires ora

defective solenoid coil. There must be slack in the

lead wires between the choke body and the bimetal

and heater assembly.

The

solenoid

coil

resistance

should be

2.09

to

2.31

ohms in a

12

volt system.

When replacing

the

cover

on

the

thermostat and

heater assembly, be certain that the choke heater

lead wires have been correctly installed in the choke

housing. Improper replacement

of

the lead wires can

cause the choke assembly to malfunction.

The wires enter the choke assembly through a small

notch that is cut in the edge of the housing.

A

cover

holds the wires in place and prevents movement

when tightened. When properly installed, the lead

wires will hang freely under the bimetal coil when the

choke is in either the open or closed position. The

end of the heater wire sleeve should be located from

1/8

inch inside the choke housing to flush with the

inside wall.

When assembling the thermo-magnetic choke, the

bimetal and heater assembly is connected asfollows:

1.

Lead tagged

G

goes to ground terminal on coil

2.

Lead tagged

H

goes to either

H1

terminal on sole-

solenoid.

noid core.

FUEL

PUMP

A

diaphragm type fuel pump is used. If fuel does not

reach the carburetor, check thefuel pump.

Todo

this,

disconnect the fu.el line at the carburetor and, while

cranking the engine slowly by hand, observewhether

fuel cornesthrough theline. Besurethereisfuel in the

tank. If the line is open and no fuel comes throug h, the

pump is defective. Failure of the pump is usually due

to a leaking diaphragm valve or valve gasket, a weak

or broken spring, or wear in the drive linkage. Oil

diluted with gasoline may indicate a faulty

diaphragm. If the operator chooses to repair the

pump rather than install a new one, the use of a

complete repair kit

is

recommended.

WARNING

Fuel leakage is a fire and explosion

=

hazard fbaf mighf cause severe per-

sonal injury

or

death.

Use

care when reassembling

fuel pump. All parts must align perfectly or pump will

leak fuel.

Fuel

Pump

Reconditioning

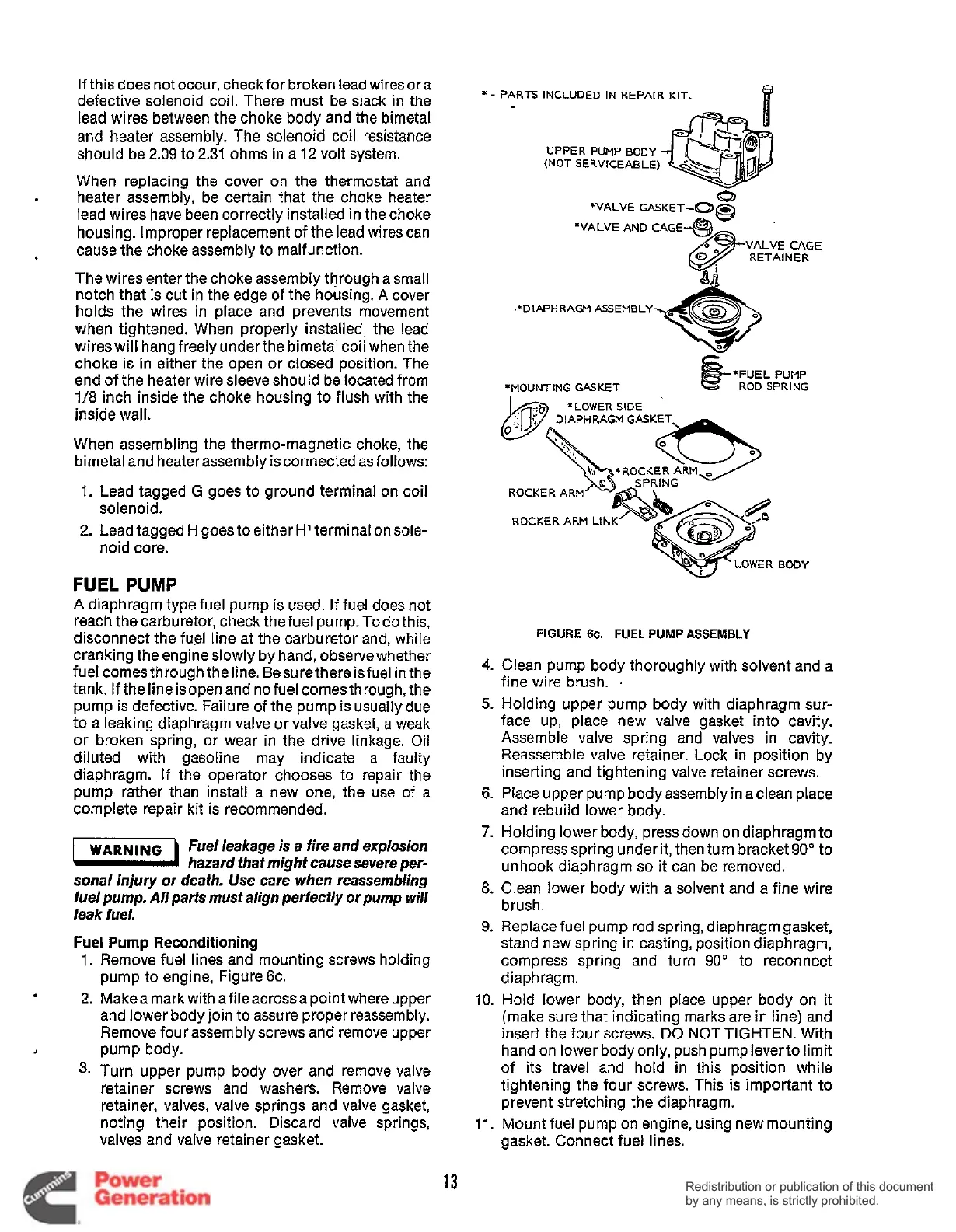

1.

2.

3.

Remove fuel lines and mounting screws holding

pump to engine, Figure 6c.

Makea mark with afileacrossapointwhere upper

and lower body join to assure proper reassembly.

Remove four assembly screws and remove upper

pump body.

Turn upper pump body over and remove valve

retainer screws and washers. Remove valve

retainer, valves, valve springs and valve gasket,

noting their position. Discard valve springs,

valves and valve retainer gasket.

i?

*

-

PARTS

INCLUDED

IN

REPAIR

KIT.

UPPERPUMPBODY

(NOT

SERVICEABLE)

*VALVE

GASKET-Q~

Q

*VALVE

AND

VALVE

CAGE

RETAINER

.*DIAPHRAGM

ASSEMBLY

*FUEL

PUMP

*MOUNTING

GASKET

ROD

SPRING

'LOWER

SIDE

DIAPHRAGM

GASKET

ROCKER

ROCKER

ARM

LINK'^^

BODY

4.

5.

6.

7.

a.

9.

10.

11.

FIGURE

6c.

FUEL

PUMP

ASSEMBLY

Clean pump body thoroughly with solvent and a

fine wire brush.

.

Holding upper pump body with diaphragm sur-

face up, place new valve gasket into cavity.

Assemble valve spring and valves in cavity.

Reassemble valve retainer. Lock in position by

inserting and tightening valve retainer screws.

Place upper pump body assembly in a clean place

and rebuild lower body.

Holding lower body, press down on diaphragmto

compress spring under it, then turn bracket

90"

to

unhook diaphragm

so

it

can be removed.

Clean lower body with a solvent and a fine wire

brush.

Replace fuel pump rod spring, diaphragm gasket,

stand new spring in casting, position diaphragm,

compress spring and turn

90"

to reconnect

d iap

h

rag m.

Hold

lower body, then place upper body on

it

(make sure that indicating marks are in line) and

insert the four screws.

DO

NOT

TIGHTEN.

With

hand

on

lower body only, push pump leverto limit

of its travel and hold in this position while

tightening the four screws. This is important to

prevent stretching the diaphragm.

Mount fuel pump on engine, using new mounting

gasket. Connect fuel lines.

13

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...