Battery

Charging

System

BATTERYCARE

Check battery cells with a hydrometer. The specific

gravity reading should be approximately 1.260 at

77°F (25OC).

If

one or more cells are low on water, add distilled

water and recharge. Keep the battery case clean and

dry. An accumulation of moisture will lead to a more

rapid discharge and battery failure.

Keep the battery terminals clean and tight. Push the

cable terminal down flush with or slightly below the

top of the battery post. After making connections,

coat the terminals with a light application of petro-

leum jelly or grease to retard corrosion.

Poor contact at the battery cable connections

is

oflen a source

of

trouble. Make sure battery cables are in good condition and that

contacting surfaces are clean and tightly connected.

Do

not

reverse battery leads. Use recommended battery tools when dis-

connecting leads to avoid mechanical battery damage.

WARNING

Ignition

of

explosive battery gases

i

might cause severe personal iniury.

Do

not smoke while servicing batteries.

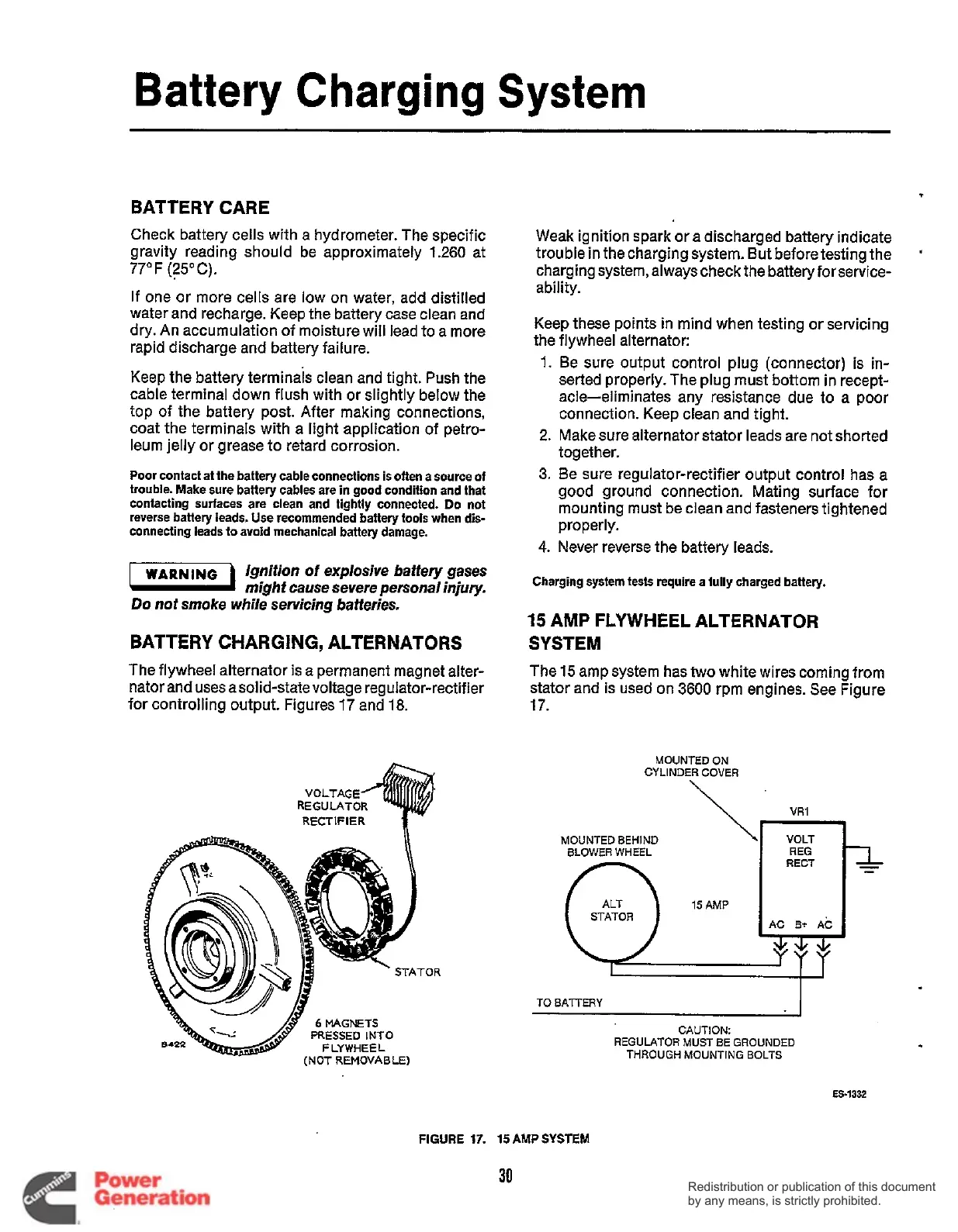

BATTERY CHARGING, ALTERNATORS

The flywheel alternator is a permanent magnet alter-

nator and uses

asolid-state voltage

regulator-rectifier

for controlling output. Figures

17

and

18.

VOLTAGE

REGULATO

RECTIFIER

PRESSED INTO

FLYWHEEL

(NOT REMOVABLE)

TOR

Weak ignition spark or a discharged battery indicate

trouble

in

the charging system. But before testing the

charging system, always check the battery for service-

ability.

'

Keep these points in mind when testing

or

servicing

the flywheel alternator:

1.

Be sure output control plug (connector)

is

in-

serted properly. The plug must bottom in recept-

acle-eliminates any resistance due to a poor

connection. Keep clean and tight.

2.

Make sure alternator stator leads are not shorted

together.

3.

Be sure regulator-rectifier output control has a

good ground connection. Mating surface for

mounting must be clean and fasteners tightened

properly.

4.

Never reverse the battery leads.

Charging system tests require a

fully

charged battery.

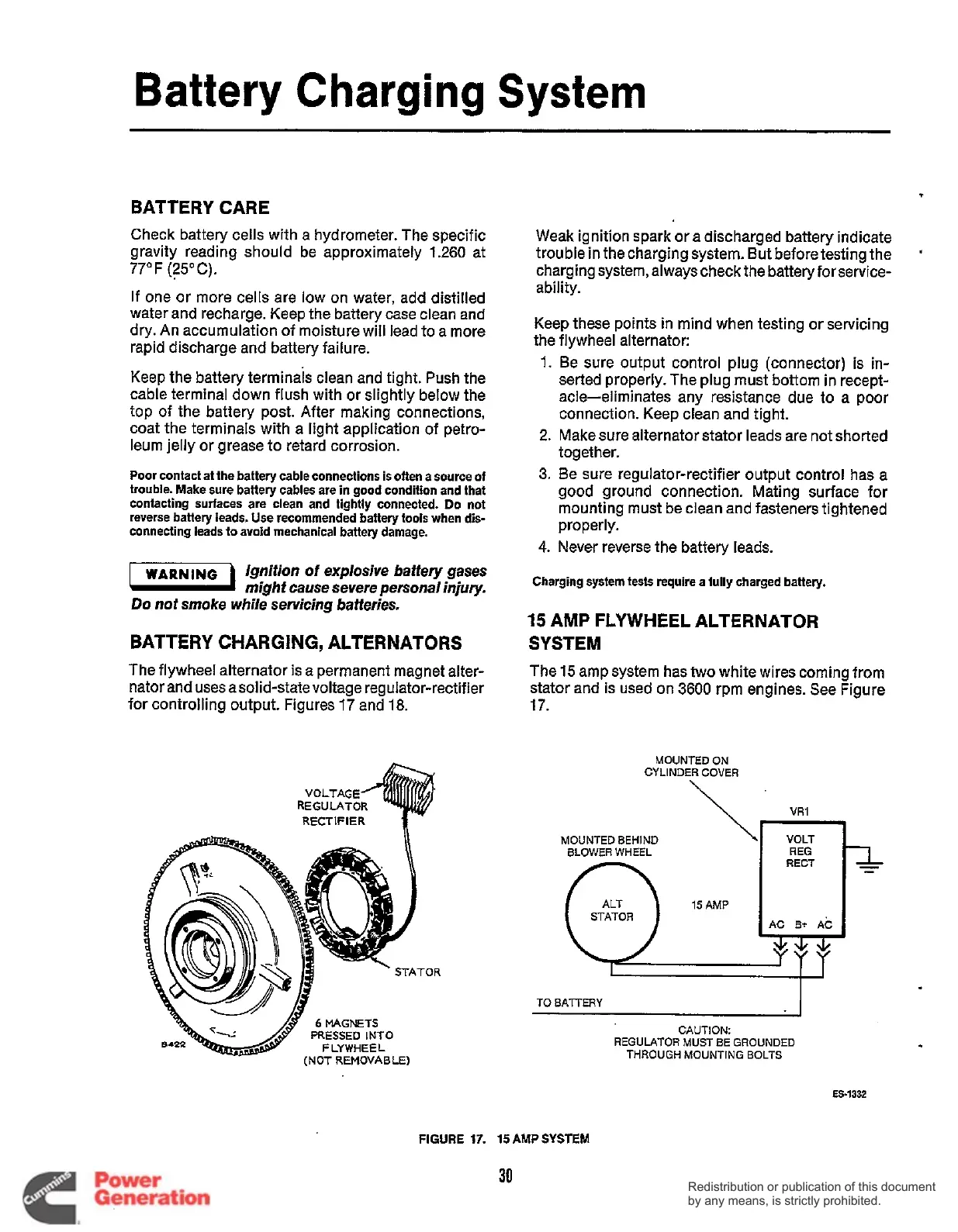

15

AMP FLYWHEEL ALTERNATOR

SYSTEM

The

15

amp system has

two

white wires coming from

stator and is used on

3600

rpm engines.

See

Figure

17.

MOUNTED ON

CYLINDER COVER

\

MOUNTED BEHIND

\

BLOWER WHEEL

VR1

VOLT

REG

RECT

AC

B+

AC

TO

BATTERY

CAUTION:

REGULATOR MUST

BE

GROUNDED

THROUGH MOUNTING BOLTS

ES-1332

FIGURE

17.

15

AMP

SYSTEM

30

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...