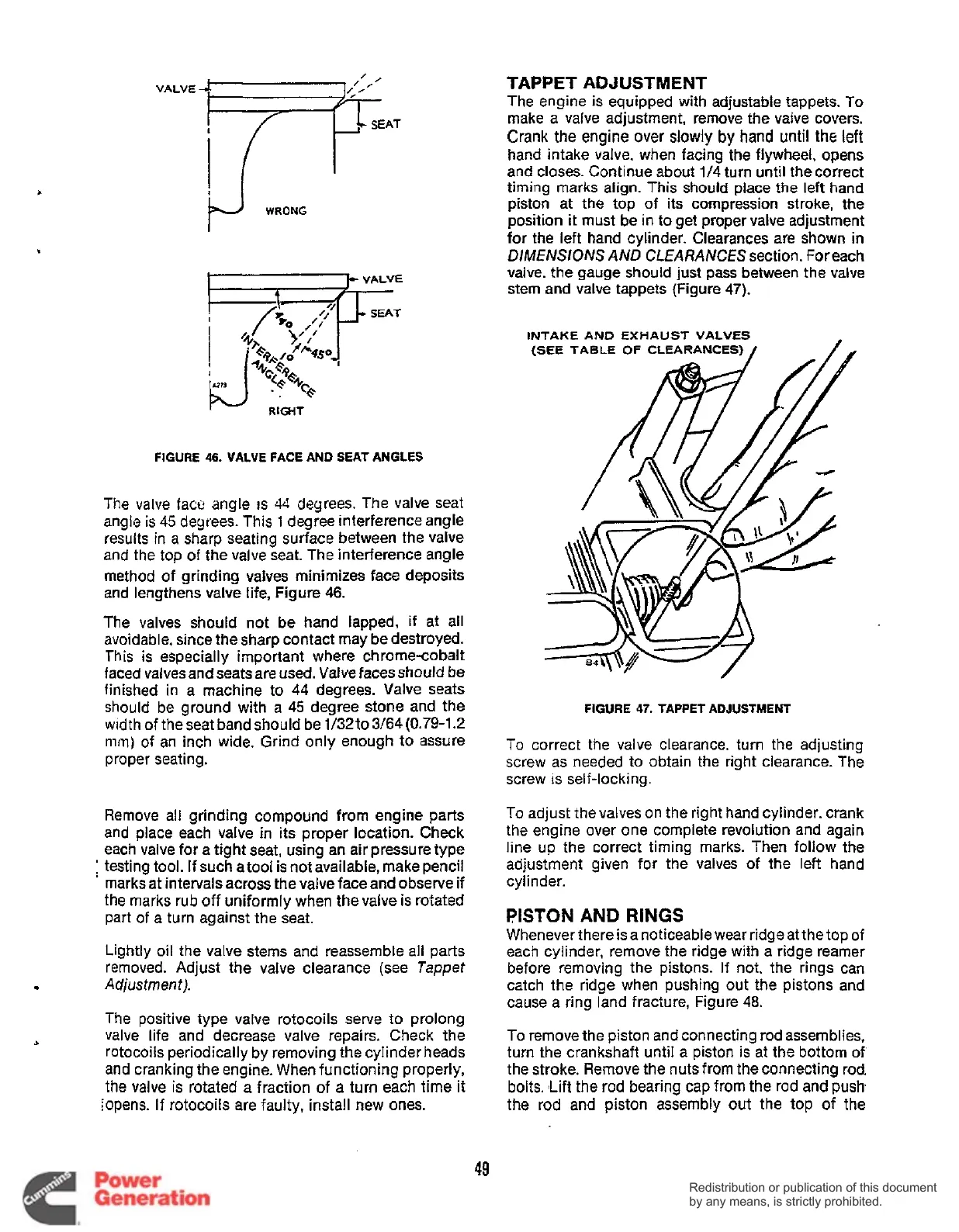

FIGURE

46.

VALVE FACE AND

SEAT

ANGLES

The valve face angle

IS

44

degrees. The valve seat

angle

is

45

degrees. This

1

degree interference angle

results in a sharp seating surface between the valve

and the top

of

the valve seat. The interference angle

method of grinding valves minimizes face deposits

and lengthens valve life, Figure

46.

The valves should not be hand lapped,

if

at all

avoidable, since the sharp contact may be destroyed.

This is especially important where chromecobalt

faced valves and seats are used. Vaive faces should be

finished in a machine to

44

degrees. Valve seats

should be ground with

a

45

degree stone and the

width of theseat bandshould be 1/32to3/64(0.79-1.2

mm)

of an inch wide. Grind only enough to assure

proper seating.

Remove all grinding compound from engine parts

and place each valve in its proper location. Check

each valve for a tight seat, using an air pressure type

:

testing tool. If such a tool

is

not available, make pencil

'

marks at intervals across the valve face and observe if

the marks rub off uniformly when the valve

is

rotated

part

of

a turn against the seat.

Lightly oil the valve stems and reassemble all parts

removed. Adjust the valve clearance (see

Tappet

Adjustment

j.

The positive type valve rotocoils serve to prolong

valve

life

and decrease valve repairs. Check the

rotocoils periodically by removing the cylinder heads

and cranking the engine. When functioning properly,

the

valve

is rotated

a

fraction of

a

turn each time it

iopens. If rotocoils are faulty, install new ones.

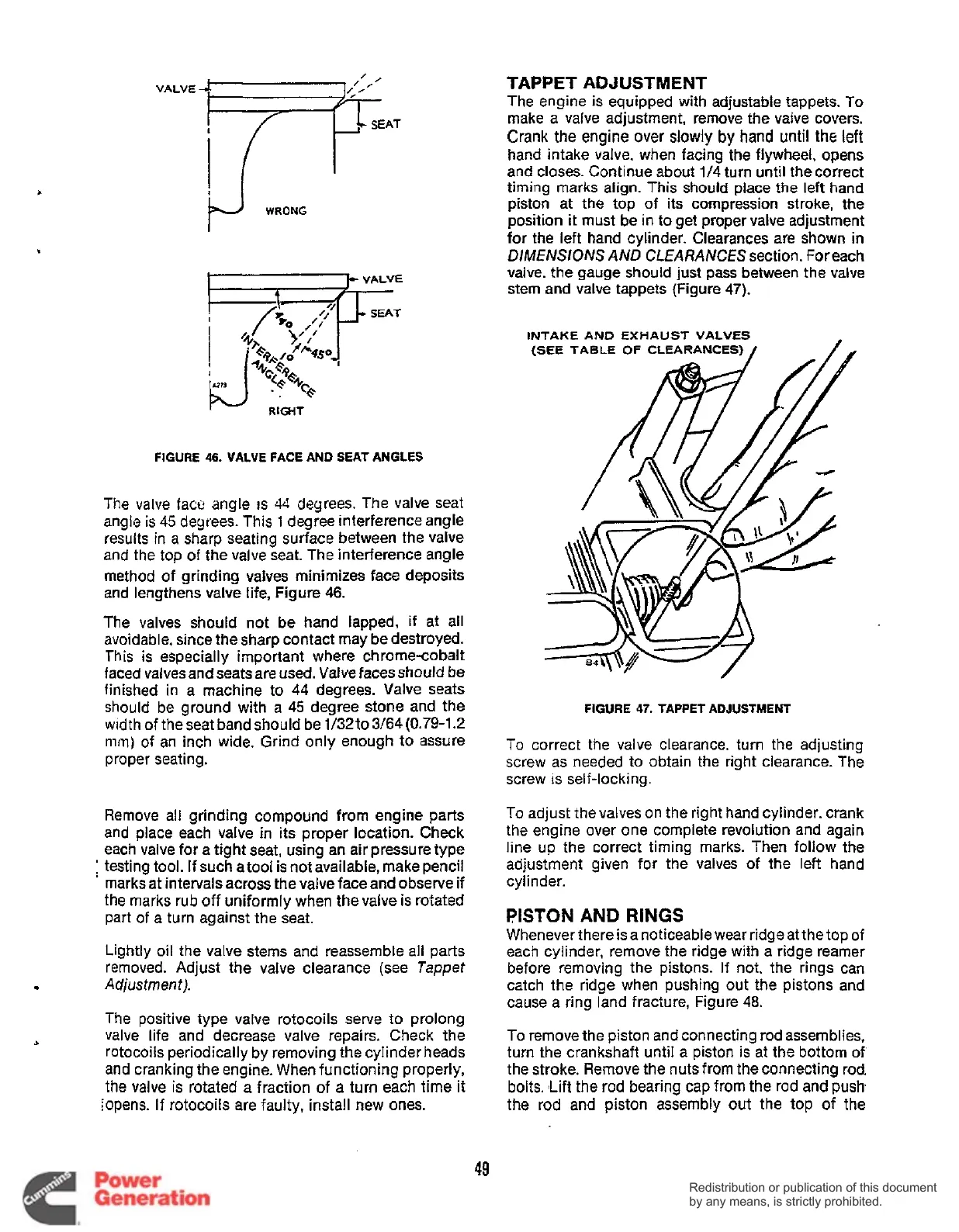

TAPPET ADJUSTMENT

The engine

is

equipped with adjustable tappets. To

make a valve adjustment, remove the valve covers.

Crank the engine

over

slowly

by

hand

until

the

left

hand intake valve. when facing the flywheel, opens

and closes. Continue about

1/4

turn until the correct

timing marks align. This should place

the

left hand

piston at the top of its compression stroke, the

position

it

must be in to get proper valve adjustment

for the left hand cylinder. Clearances are shown

in

DIMENSIONS

AND CLEARANCES

section. For each

valve. the gauge should just pass between the valve

stem and valve tappets (Figure

47).

INTAKE

AND

EXHAUST

VALVES

(SEE

TABLE

OF

CLEARANCE

FIGURE

47.

TAPPET

ADJUSTMENT

To

correct the valve clearance, turn the adjusting

screw as needed to obtain the right clearance. The

screw

is

self-locking.

To adjust the valves on the right hand cylinder. crank

the engine over one complete revolution and again

line up the correct timing marks. Then follow the

adjustment given for the valves of the left hand

cylinder.

PISTON AND

RINGS

Whenever there is a noticeable wear ridge at the top

of

each cylinder, remove the ridge with a ridge reamer

before removing the pistons.

If

not. the rings can

catch the ridge when pushing out the pistons and

cause a ring land fracture, Figure

48.

To remove the piston and connecting rod assemblies,

turn the crankshaft until a piston

is

at the bottom of

the stroke. Remove the nuts from the connecting rod,

bolts. ILift the rod bearing cap from the rod and push

the rod and piston assembly out the top of the

49

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...