ADJUSTABLE

GOVERNOR

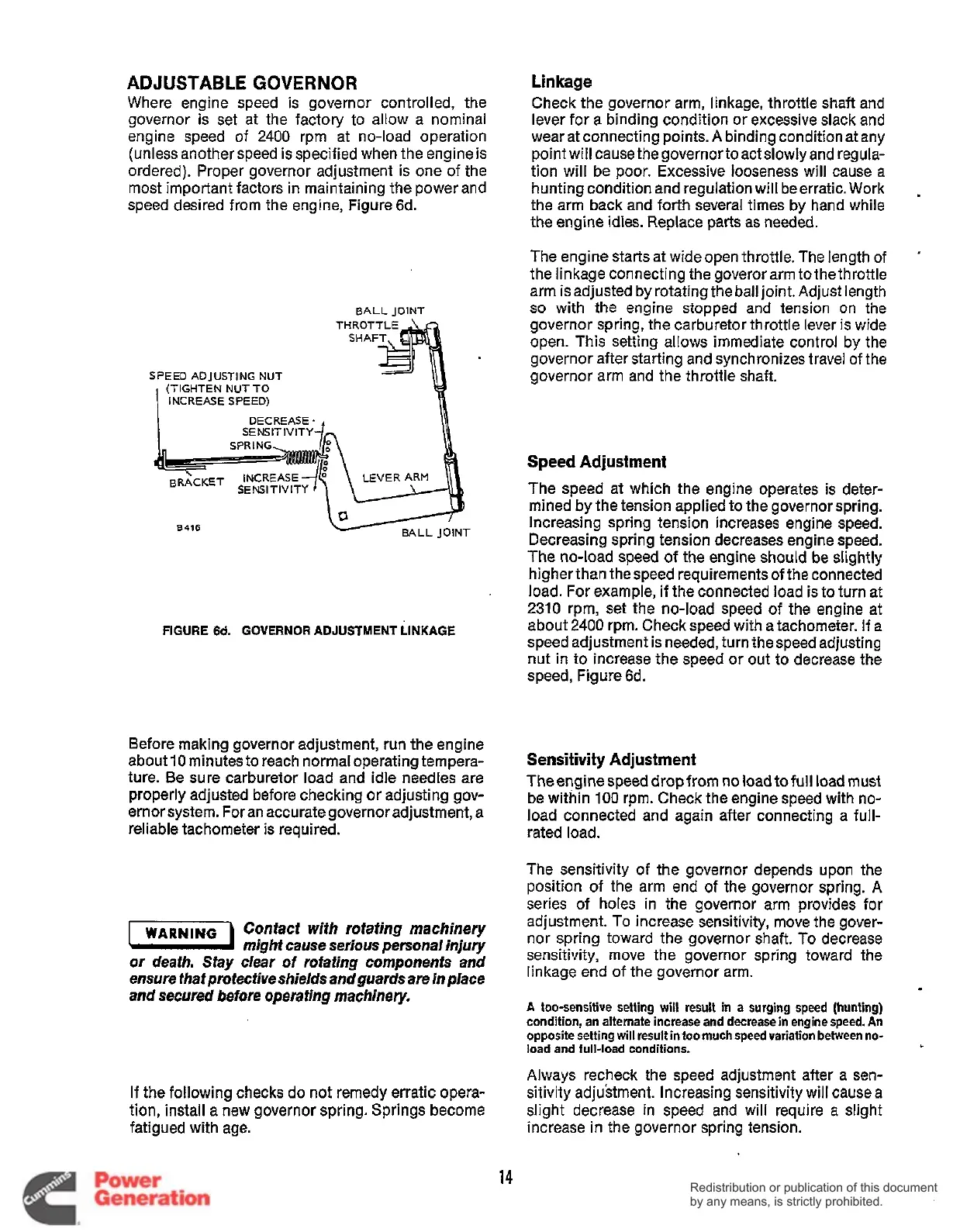

Where engine speed is governor controlled, the

governor is set at the factory to allow a nominal

engine speed of

2400

rprn

at no-load operation

(unless another speed

is

specified when the engine is

ordered). Proper governor adjustment

is

one of the

most important factors in maintaining the power and

speed desired from the engine, Figure 6d.

Linkage

Check the governor arm, linkage, throttle shaft and

lever for a binding condition or excessive slack and

wear at connecting points.

A

binding condition at any

point will cause thegovernortoact slowly and regula-

tion will be poor. Excessive looseness will cause a

hunting condition and regulation will beerratic. Work

the arm back and forth several times by hand while

the engine idles. Replace parts as needed.

.

The engine starts at wide open throttle. The length of

the linkage connecting the goverorarm tothethrottle

arm is adjusted by rotating the ball joint. Adjust length

so

with the engine stopped and tension on the

governor spring, the carburetor throttle lever is wide

open. This setting allows immediate control by the

governor after starting and synchronizes travel of the

governor arm and the throttle shaft.

'

BALL JOINT

SPEED ADJUSTING NUT

(TIGHTEN NUT TO

INCREASE SPEED)

SE NSlT IVlTY

Speed

Adjustment

The speed at which the engine operates

is

deter-

mined by

the

tension applied to the governor spring.

Increasing spring tension increases engine speed.

Decreasing spring tension decreases engine speed.

The no-load speed of the engine should be slightly

higher than the speed requirements

of

the connected

load. For example, if the connected load is to turn at

2310

rpm, set the no-load speed of the engine at

about

2400

rpm. Check speed with a tachometer. If a

speed adjustment is needed, turn the speed adjusting

nut in to increase the speed or out to decrease the

speed, Figure 6d.

8416

FIGURE 6d. GOVERNOR ADJUSTMENT LINKAGE

Before making governor adjustment, run the engine

about

10

minutes to reach normal operating tempera-

ture. Be sure carburetor load and idle needles are

properly adjusted before checking or adjusting gov-

ernor system. For an accurategovernor adjustment,

a

reliable tachometer is required.

Sensitivity Adjustment

Theenginespeeddropfrom no loadtofull load must

be within

100

rpm. Check the engine speed with no-

load connected and again after connecting a full-

rated load.

WARNING

Confacf wifh rofafing machinery

n

mighf cause serious personal injury

or

deafh. Say clear

of

rofating componenfs and

ensure that profecfive shields and guards are in place

and secured before operating machinery.

If the following checks

do

not remedy erratic opera-

tion, install a

new

governor spring. Springs become

fatigued with age.

The sensitivity of the governor depends upon the

position of the arm end of the governor spring.

A

series of holes in the governor arm provides for

adjustment. To increase sensitivity, move the gover-

nor spring toward the governor shaft.

To

decrease

sensitivity, move the governor spring toward the

linkage end of the governor arm.

A

too-sensitive setting will result in a surging speed (hunting)

condition, an alternate increase and decrease in engine speed. An

opposite setting

will

result in too

much

speed variation between no-

load and full-load conditions.

Always recheck the speed adjustment after a sen-

sitivity adjustment. Increasing sensitivity will cause a

slight decrease in speed and will require

a

slight

increase in the governor spring tension.

14

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...