TESTING

ALTERNATOR

For tesfing this system, use

a

voltmeter-ohmmeter

such

as

a

Simpson

270.

Listed below are various

alternator problems with individual test procedures

following.

No

Output

-

Stator Assembly

Examine 1ead.wires for loose or broken connections at

the regutator and rectifier. Use the

Rxl

scale on the

ohmmeter for detecting opens

in

the stator. Dis-

connect the three wires that come from alternator

stator (two black, one red). Connect ohmmeter test

leads

to

red leadwire and ground to check continuity.

The ohmmeter reading should be about 2.0-ohms.

See Figure 18.

Next connect meter

to

black leadwires and ground.

Approximately 0.1-ohm should be read from either

black lead

to

ground. If noconnection existsbetween'

ground and black leads, stator assembly should be

replaced.

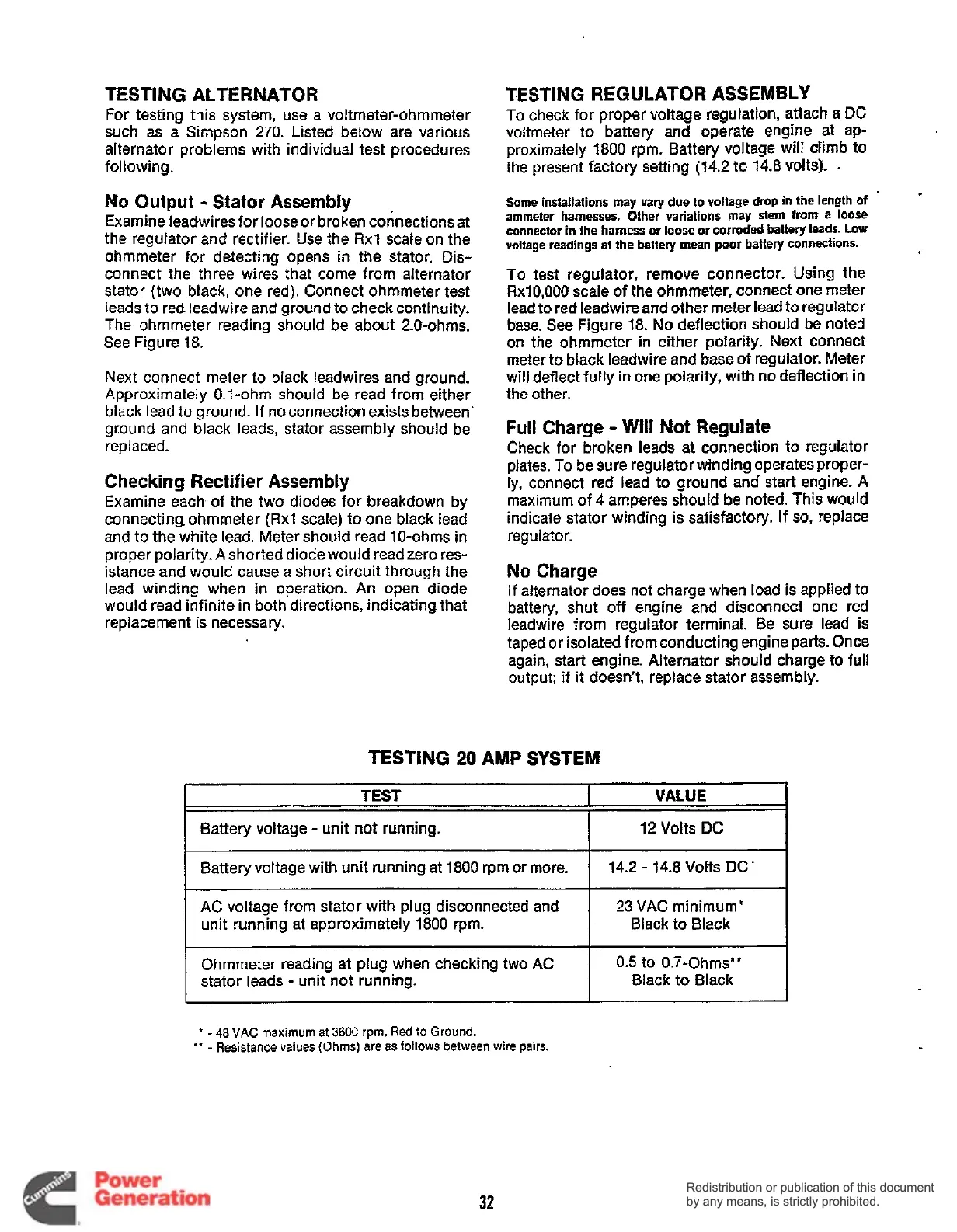

TEST

Battery voltaye

-

unit

not

running.

Checking Rectifier Assembly

Examine each of the two diodes for breakdown by

connecting. ohmmeter (Rxl scale) to one black lead

and to the white lead. Meter should read 10-ohms

in

proper polarity.

A

shorted diode would readzero res-

istance and would cause a short circuit through the

lead winding when in operation. An open diode

would read infinite in both directions, indicating that

replacement is necessary.

VALUE

12 Volts

DC

TESTING

REGULATOR

ASSEMBLY

To

check for proper voltage regulation, attach a

DC

voltmeter to battery and operate engine at ap-

proximately

I800

rpm. Battery voltage will climb to

the present factory setting (14.2 to

14.8

volts).

.

Some installations may vary due to voltage drop

in

the length

of

ammeter harnesses. Other variations may stem from a

loose

connector in the harness or loose or corroded battery

leads.

LOW

voltage readings at the battery mean poor battery connections.

To

test regulator, remove connector. Using the

Rx10,OOO scale of the ohmmeter, connect one meter

lead to red leadwire arid other meter lead to regulator

base. See Figure 18.

No

deflection should be noted

on the ohmmeter

in

either polarity. Next connect

meter

to

black leadwire and base of regulator. Meter

will

deflect fuily

in

one polarity, with no deflection in

the other.

AC

voltage from stator with plug disconnected and

unit running at approximately 1800

rpm.

Ohmmeter reading at plug when checking two AC

stator leads

-

unit not running.

Full

Charge

-

Will

Not Regulate

Check for broken leads at connection to regulator

plates.

To

be sure regulator winding operates proper-

ly,

connect red lead to ground and start engine.

A

maximum

of

4

amperes should be noted. This would

indicate stator winding is satisfactory.

If

so,

replace

regulator.

23

VAC

minimum'

.

Black to Black

0.5

to 0.7-Ohms"

Black to Black

No

Charge

If

alternator does not charge when load

is

applied to

battery, shut off engine and disconnect one red

leadwire from regulator terminal. Be sure lead is

taped or isolated from conducting engine

parts.

Once

again, start engine. Alternator should charge

to

full

output; if it doesn't, replace stator assembly.

TESTING

20

AMP

SYSTEM

I

Battery voltage with

unit

running at

1800

rpm

or

more.

1

14.2

-

14.8

Volts

DC

'

I

-

-

48

VAC

maximum at

3600

rpm, Red

to

Ground.

**

-

Resistance values (Ohms) are as follows between wire pairs.

32

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...