Starting

System

’

STARTER

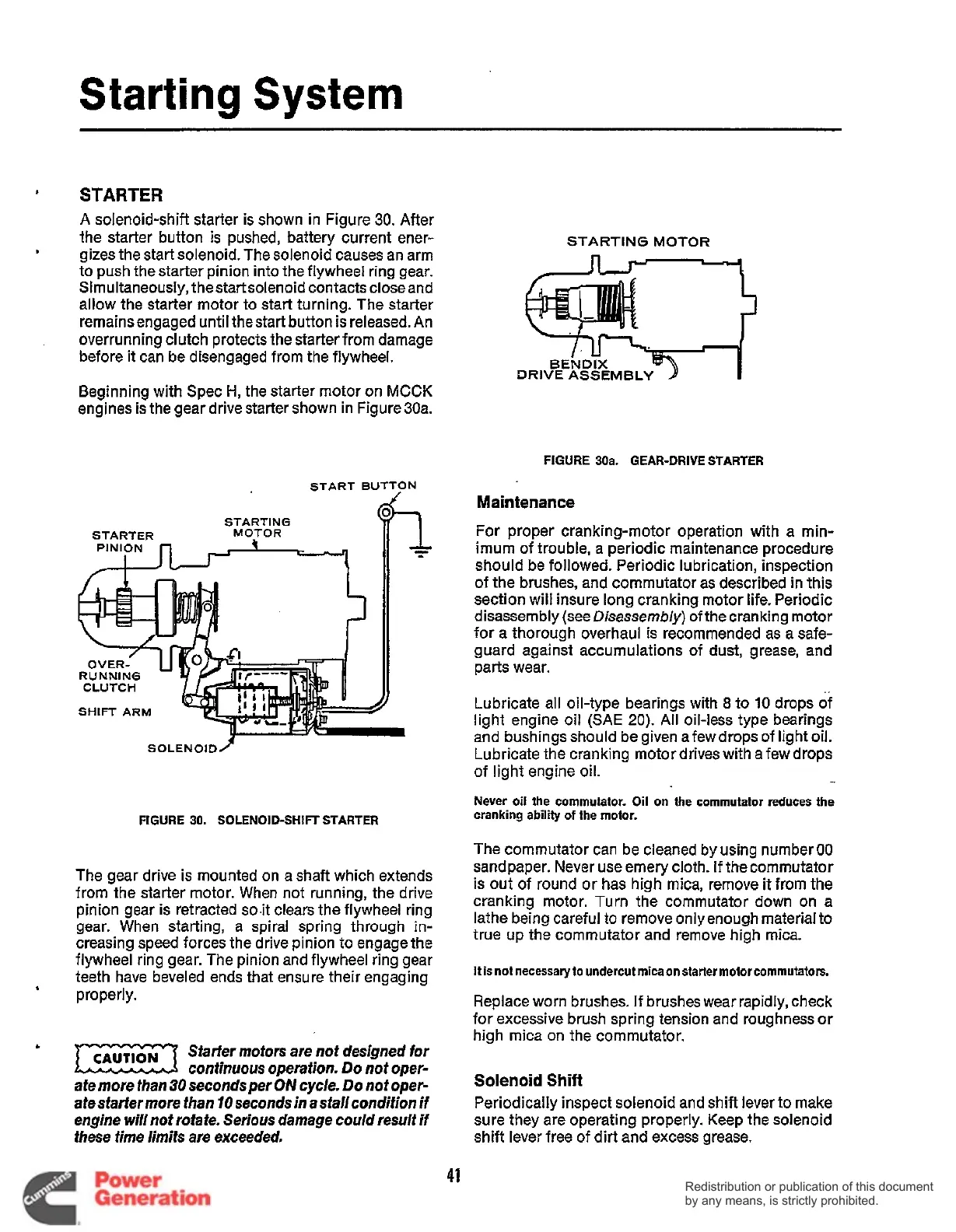

A

solenoid-shift starter is shown in Figure

30.

After

the starter button is pushed, battery current ener-

gizes the start solenoid. The solenoid causes an arm

to push the starter pinion into the flywheel ring gear.

Simultaneously, the start solenoid contacts close and

allow the starter motor to start turning. The starter

remainsengaged until thestart button is released. An

overrunning clutch protects the starter from damage

before it can be disengaged from the flywheel.

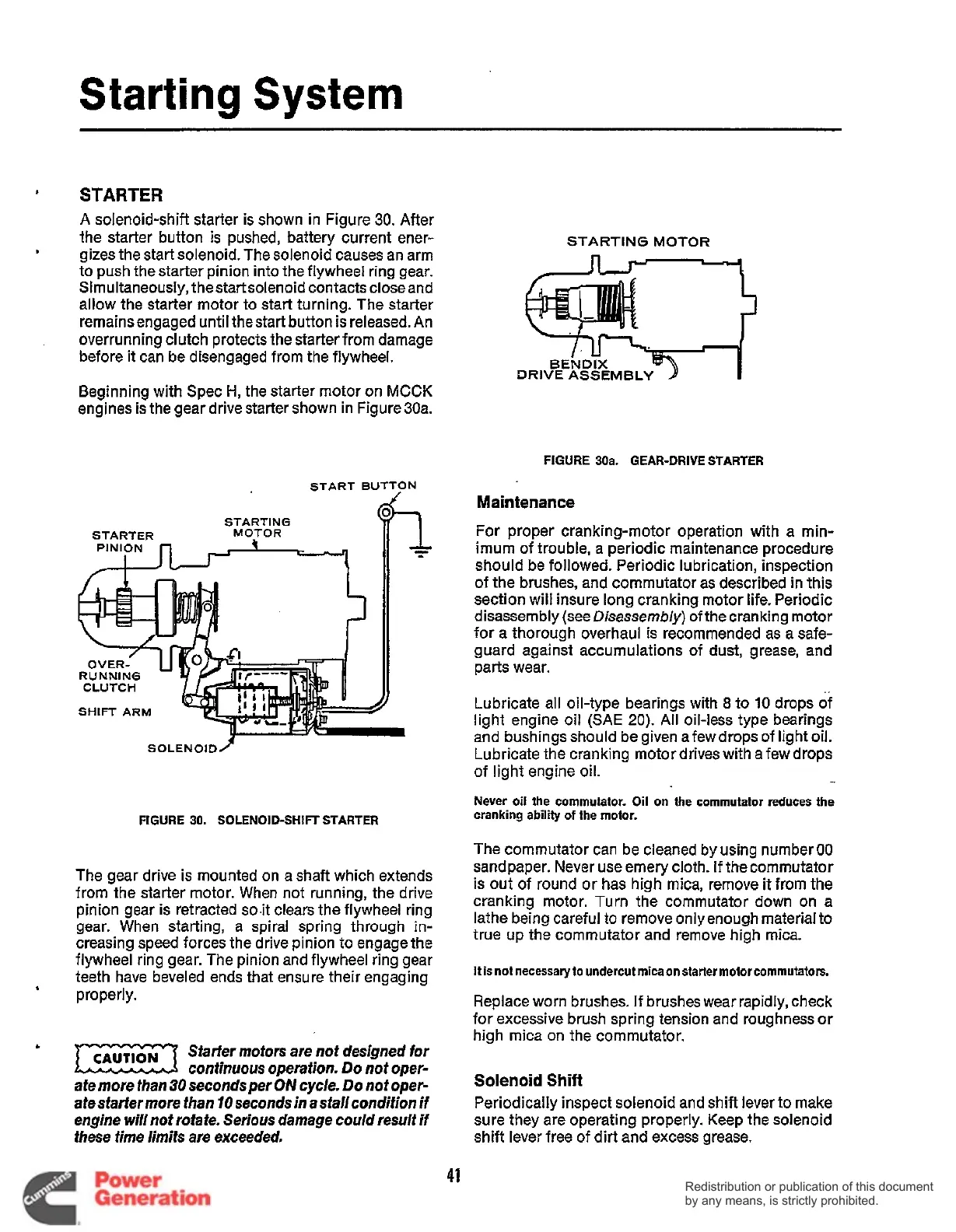

Beginning with Spec

H,

the starter motor on MCCK

engines

is

the gear drive starter shown in Figure 30a.

STARTING MOTOR

’

.

FIGURE 30a. GEAR-DRIVE STARTER

START

BUTTON

Maintenance

For proper cranking-motor operation with a min-

imum of trouble, a periodic maintenance procedure

should be followed. Periodic lubrication, inspection

of the brushes, and commutator as described in this

section will insure long cranking motor life. Periodic

disassembly (see

Disassembly)

of

the cranking motor

for a thorough overhaul is recommended as a safe-

guard against accumulations of dust, grease, and

parts wear.

Lubricate all oil-type bearings with

8

to

10

drops

of

light engine oil

(SAE

20).

All

oil-less type bearings

and bushings should be given afewdrops of light oil.

Lubricate the cranking motor drives with afew drops

of light engine oil.

-

CLUTCH

SHIFT

ARM

SOLENOID

Never

oil

the commutator. Oil

on

the commutator reduces the

FIGURE 30.

SOLENOID-SHIFT

STARTER cranking ability

of

the motor.

The commutator can be cleaned by using number

00

The gear drive is mounted on a shaft which extends

from the starter motor. When not running, the drive

pinion gear is retracted soit clears the flywheel ring

gear. When starting, a spiral spring through in-

creasing speed forces the drive pinion to engage the

flywheel ring gear. The pinion and flywheel ring gear

teeth have beveled ends that ensure their engaging

properly.

*

b

Starter motors are not designed

for

continuous operation.

Do

not oper-

ate more than

30

secondsper

ON

cycle.

Do

not oper-

ate starter more fhan

70

seconds in a stall condition

if

engine will not rotate. Serious damage could result

if

these time limits are exceeded.

sandpaper. Never use emery cloth. If the commutator

is out

of

round or has high mica, remove

it

from the

cranking motor. Turn the commutator down on

a

lathe being careful to remove onlyenough material to

true up the commutator and remove high mica.

It

is not necessaryto undercut micaon

startermotorcommutators.

Replace worn brushes. If brushes wear rapidly, check

for excessive brush spring tension and roughness or

high mica on the commutator.

Solenoid

Shift

Periodically inspect solenoid and shift lever to make

sure they are operating properly. Keep the solenoid

shift lever free of dirt and excess grease.

41

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...